- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

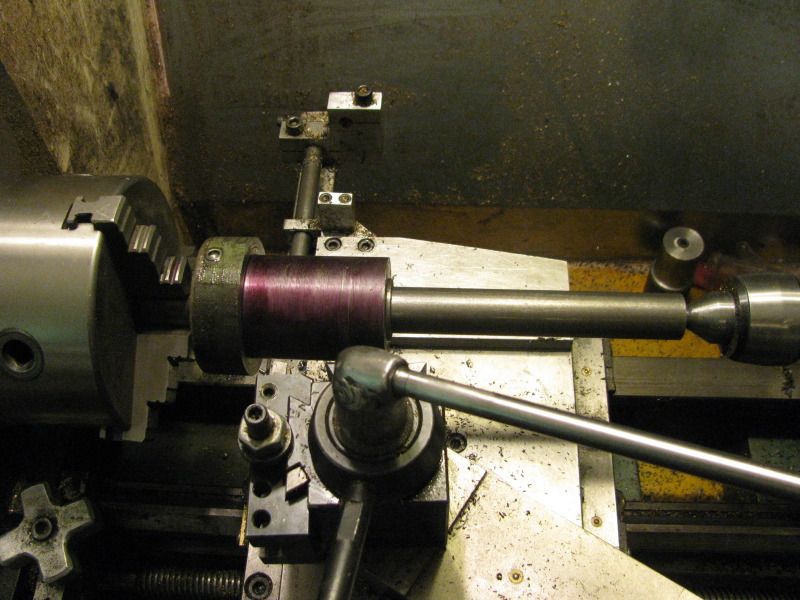

.53" removed at .01/pass would have strained my patience level ;D

Now that one end is down to 2", I'd think you could reverse the direction and use the normal jaw for drilling/boring/reaming. If you can drill out to the largest size you can and then bore with small cuts, you should get a straight hole.

Now that one end is down to 2", I'd think you could reverse the direction and use the normal jaw for drilling/boring/reaming. If you can drill out to the largest size you can and then bore with small cuts, you should get a straight hole.