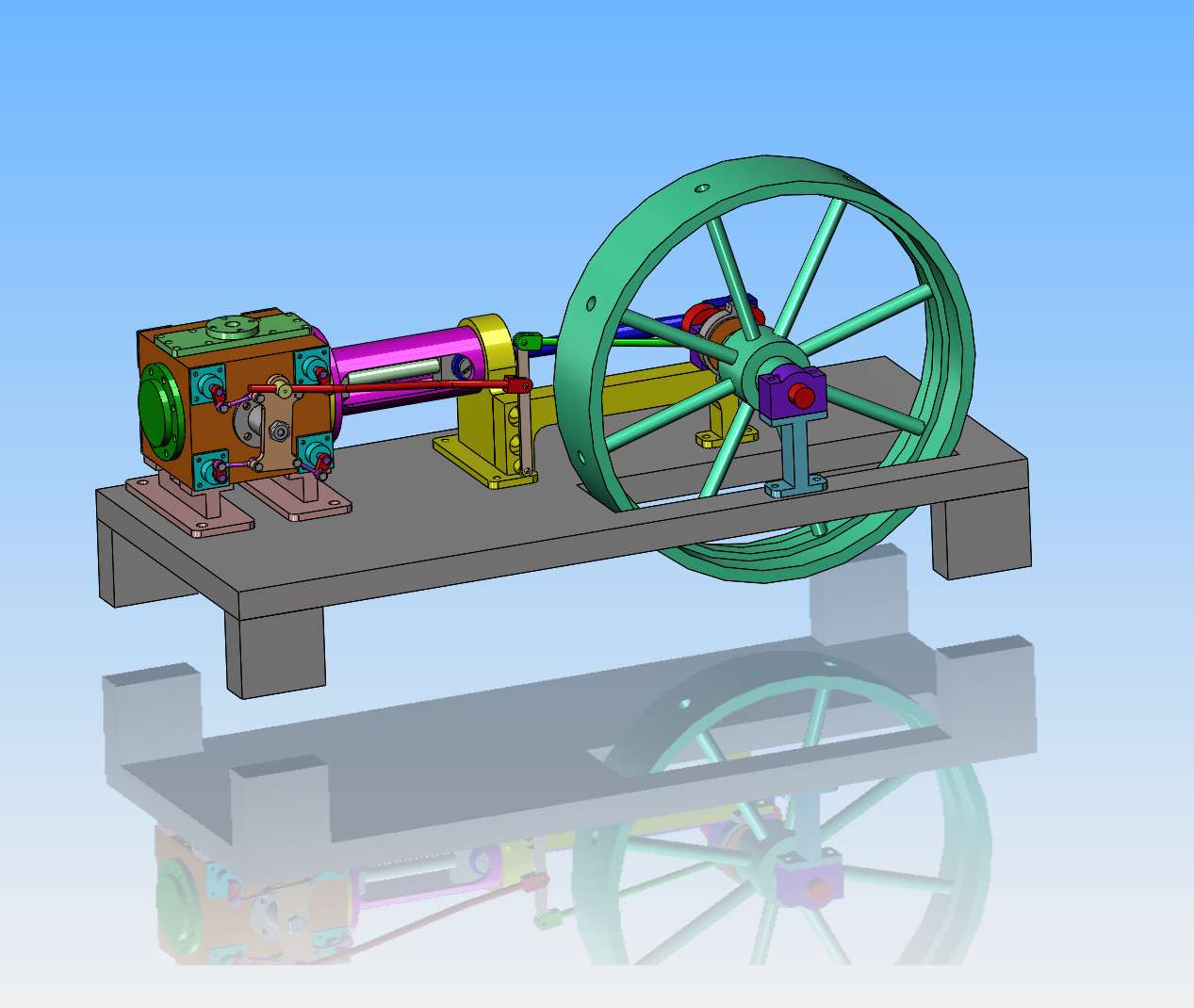

Brian, this will be an exciting build for me to see, I run one when I was a little fellow, I was told keep the boiler full and all the oil drips full, it was installed in 1895 at an Irrigation company in south Louisiana that pumped water for the Bayou raising it 26 feet to the irrigation canal that went for four miles to another crude oil engine that raised the water 15 feet, I would spend a lot time there with the old men and they taught me a lot, so I probably 13 running the 11-7 shift, I thought I was good till one night it started pounding like the floor was going to break, went around the valve side and on to the square bushing had a worn edge and that dashpot would drip the valve early, I stood there for four hours lifting it so it could close, little kid did not know where others were to replace, guess I did not learn a lot after all, the old fellow came to take my place at 7 AM and stat on a bucket and rolled his cigarette, started smoking, not looking to the kid, I let that valve drop then he coming running, go a fresh on screwed it and run perfect, the flywheel was in two halves, Hughe nuts on the shaft and the outer ring had several nuts on the inside, I had one rope that was three inch diameter it was continues from one pulley to the other, sure I figure it out even learned how to weave rope, then in 1974 big boss steam out in went a Wakesha, with two jack stands, would not pump as slow nor as fast, we were stuck it, the original was fired by wood, that is all the did cut and split wood for the boilers, they worked year around, then they discovered oil in 1901, switch to burring crude oil then later switch it to natural gas, that got the boiler up quick, I will try to get some photos together, I would love purchase some plans of that, that would bring back a lot of fine remembering , sill love the smell of steam and oil, would you consider selling me a print