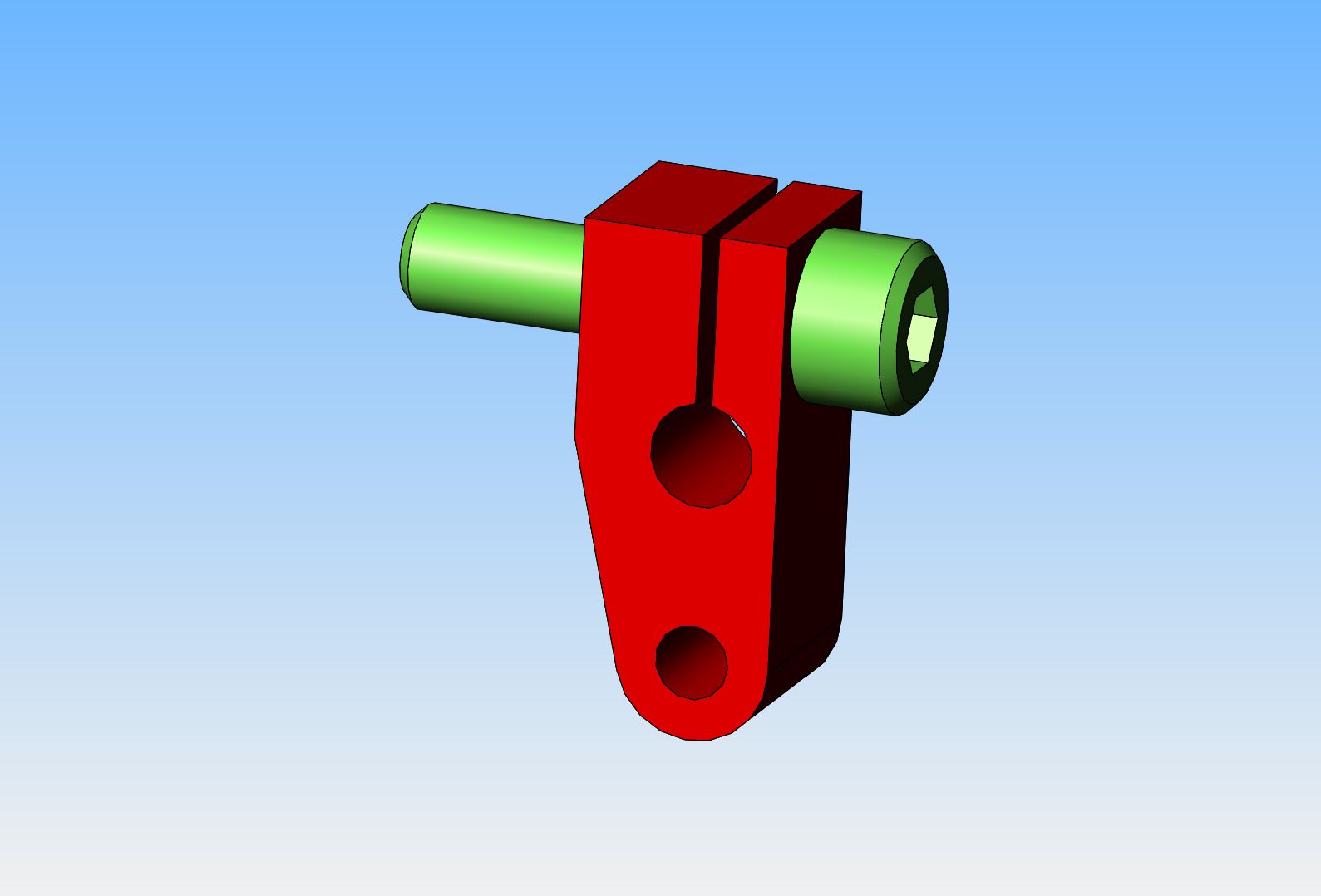

Yes that is the solid part, also see my additional reply on MEM

It's just like any other slide valve equiped steam engine, when the valve is in mid position both passages to the ends of the cylinder are closed by the valve

It's just like any other slide valve equiped steam engine, when the valve is in mid position both passages to the ends of the cylinder are closed by the valve