Sshire

Well-Known Member

- Joined

- Jun 29, 2011

- Messages

- 936

- Reaction score

- 259

Boring Head Presetting Tool

If youve followed (and how couldnt you) my Elmers #33 build log, you saw that I used a boring head to mill the inside and outside curves on the crank.

The question came up about how the head was set for the radius.

When I did the operations, I guessed a lot, did a lot of adjusting on the boring head and generally moved the X and Y handles until the tools path matched my layout lines on the part.

There had to be a better way and heres my take on it.

The Mark I Boring Head Presetter

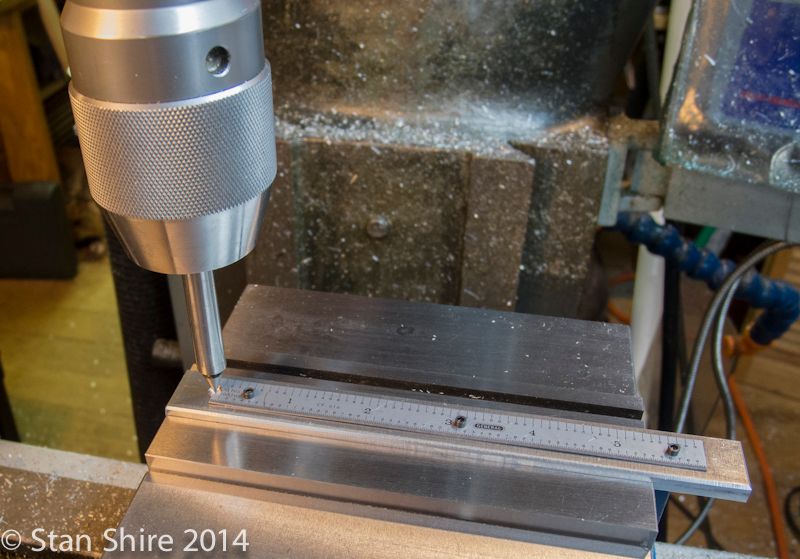

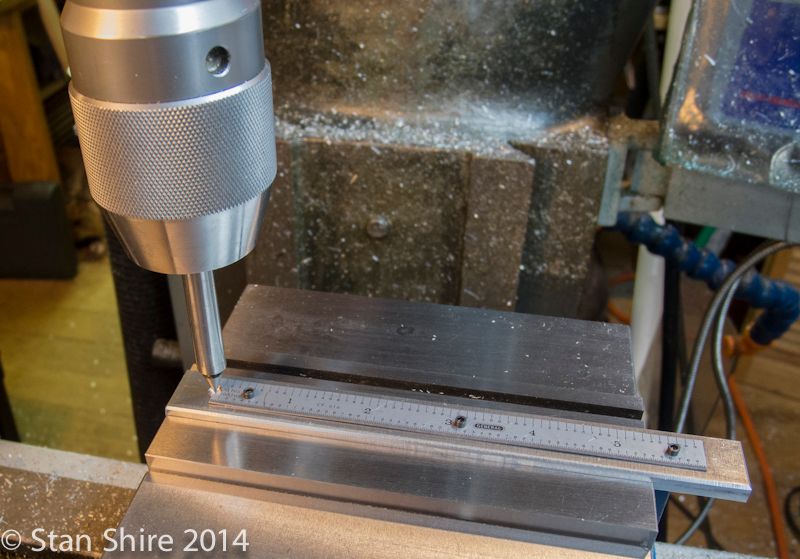

Nothing more than a 6061 flatbar with a 6 scale attached with 2-56 SHCS

The tool is zeroed under the spindle.

The boring head is mounted and the tool tip is brought close to the 6 scale

And, the boring head is adjusted to the desired radius.

Disclaimer

I havent tried this yet and dont know how precise it is. It should be close enough for a starting measurement. I think it could be very precise if a caliper was used instead of the 6 scale.

Enjoy!

If youve followed (and how couldnt you) my Elmers #33 build log, you saw that I used a boring head to mill the inside and outside curves on the crank.

The question came up about how the head was set for the radius.

When I did the operations, I guessed a lot, did a lot of adjusting on the boring head and generally moved the X and Y handles until the tools path matched my layout lines on the part.

There had to be a better way and heres my take on it.

The Mark I Boring Head Presetter

Nothing more than a 6061 flatbar with a 6 scale attached with 2-56 SHCS

The tool is zeroed under the spindle.

The boring head is mounted and the tool tip is brought close to the 6 scale

And, the boring head is adjusted to the desired radius.

Disclaimer

I havent tried this yet and dont know how precise it is. It should be close enough for a starting measurement. I think it could be very precise if a caliper was used instead of the 6 scale.

Enjoy!