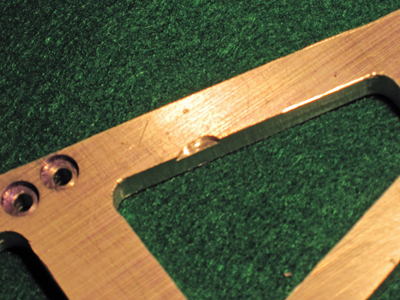

Help!!!

I had the piece bolted down to a fixture and ran the end mill just a little too close to one of the mounting screws.

The mill literally unscrewed the hold-down and the work shifted before I could get it turned off.

Here's the result:

Any ideas on how to hide it?? I really don't want to start over.

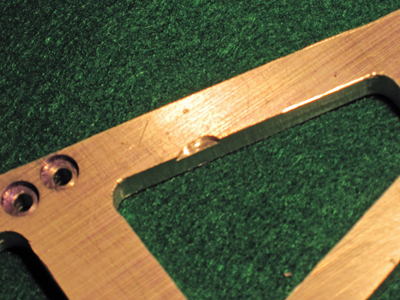

I had the piece bolted down to a fixture and ran the end mill just a little too close to one of the mounting screws.

The mill literally unscrewed the hold-down and the work shifted before I could get it turned off.

Here's the result:

Any ideas on how to hide it?? I really don't want to start over.