M130

Member

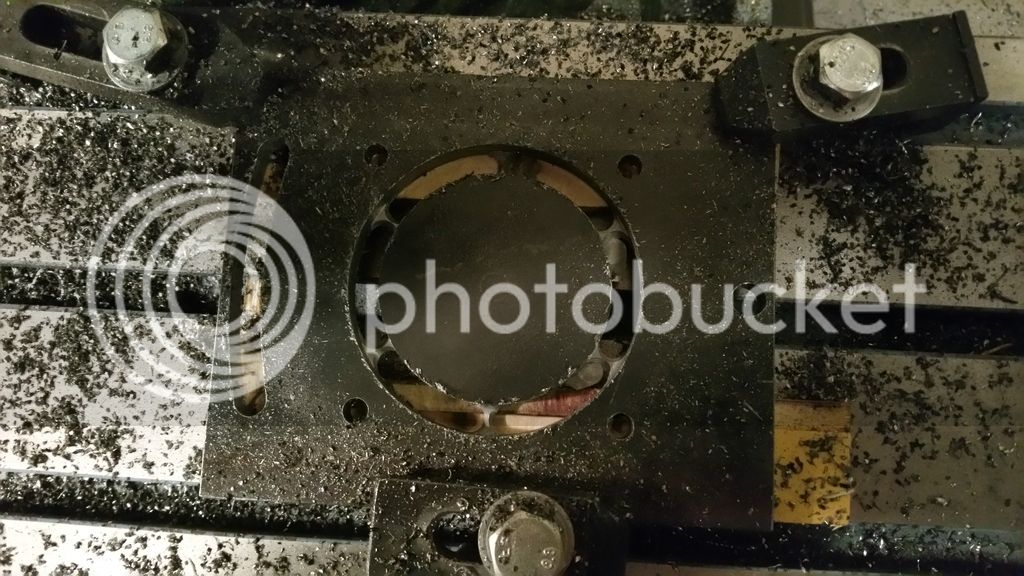

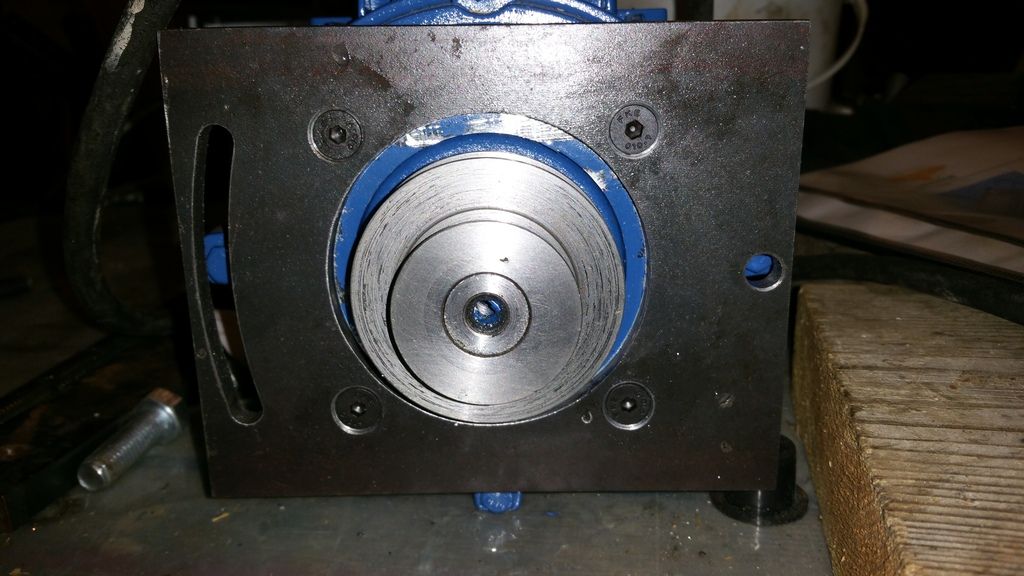

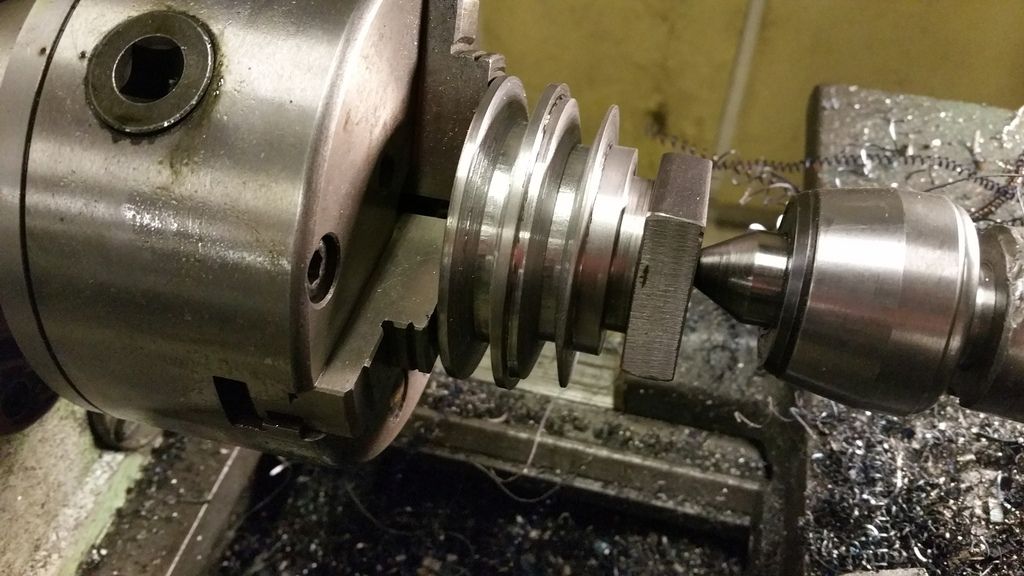

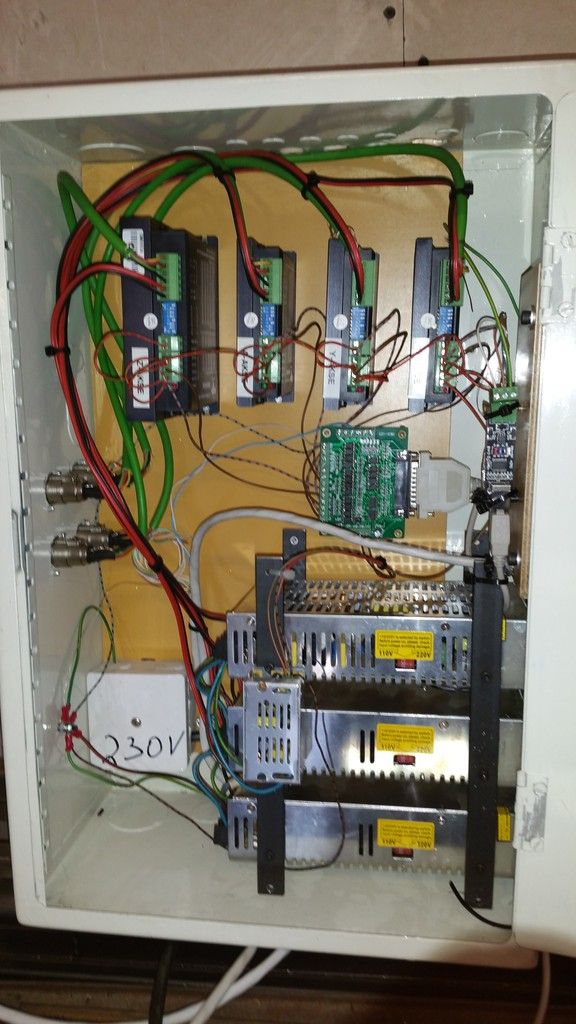

I have done a 3Phase conversion on my G0704 type mill. I have also done a cnc conversion on this mill, but in this thread I will show the motor and belt drive conversion as I have not found many such conversions with 3phase motor and vfd. The plans for the belt drive are purchased from hossmachine and I have made the conversion based on those.

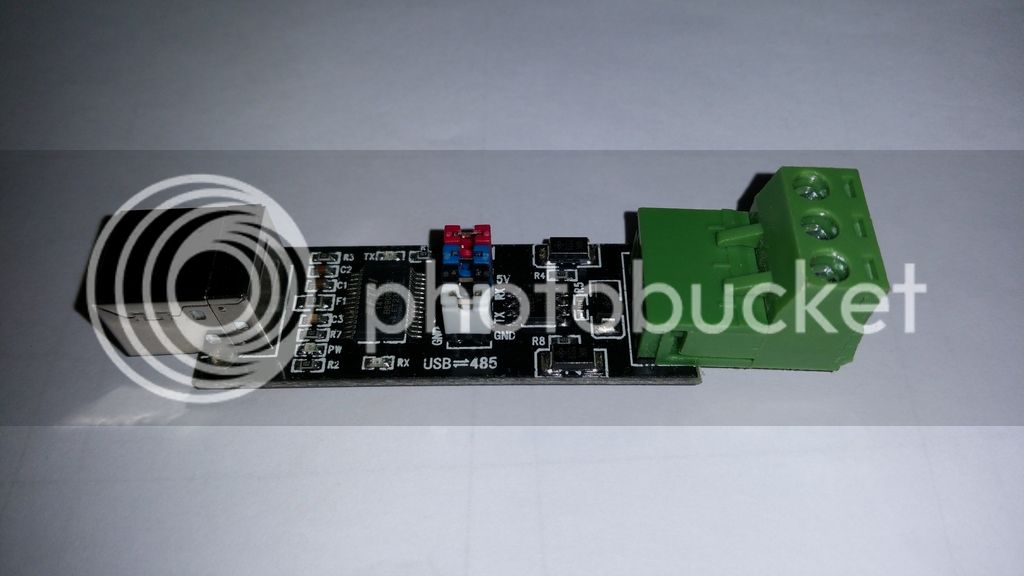

I'm using a Bevi 1hp/0.75 kw 50 Hz 4 pole motor and a 2.2 kw huangyang vfd. The motor is rated 1430 rpm/50hz and give about 2860 rpm/100hz.

Regards Morten

I'm using a Bevi 1hp/0.75 kw 50 Hz 4 pole motor and a 2.2 kw huangyang vfd. The motor is rated 1430 rpm/50hz and give about 2860 rpm/100hz.

Regards Morten

Last edited: