- Joined

- Dec 12, 2012

- Messages

- 2,220

- Reaction score

- 1,285

I am currently running a thread on making a model shaper

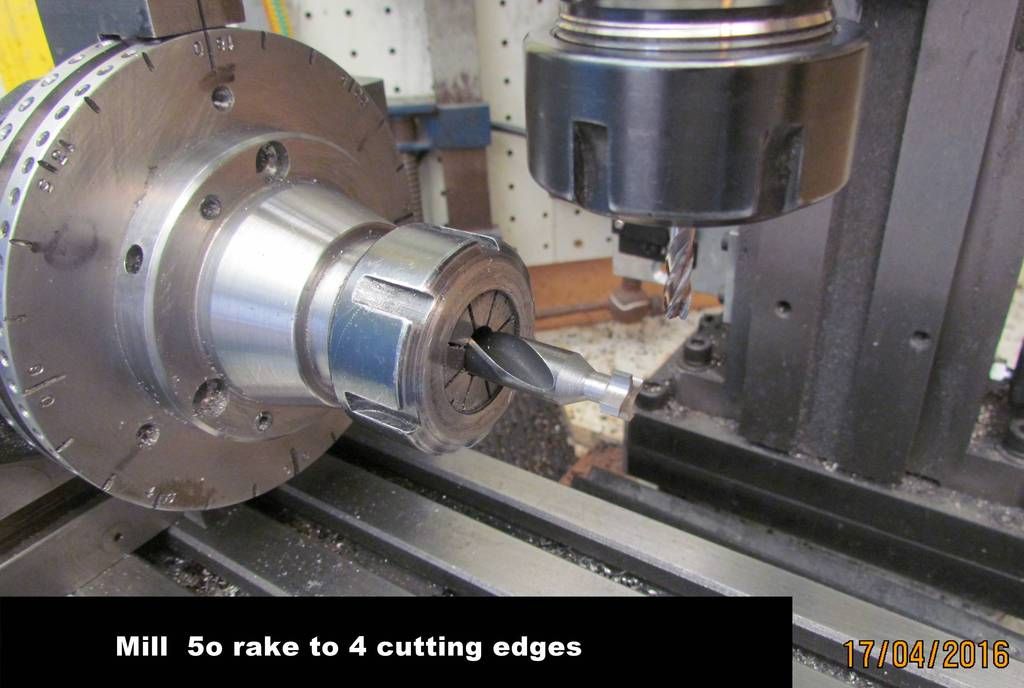

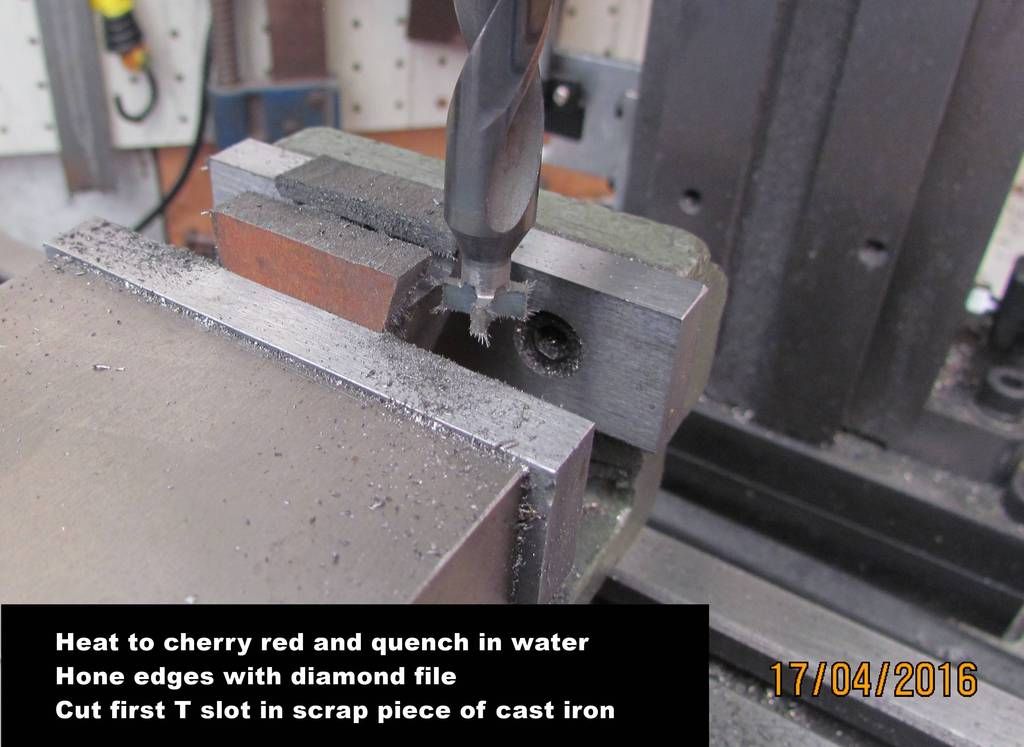

At the moment I am fabricating the table.Starting with a piece of 50x50x8 ms angle.The top of the table I wanted to use cast iron and to machine small

T slots,so decided to make a T slot cutter.My limited supply of silver steel

had nothing suitable,what I did have was a box old drills.So I turned down the shank of an 11mm drill made the cutter,hardened and ground it works better than a bought one and I can still use the drill

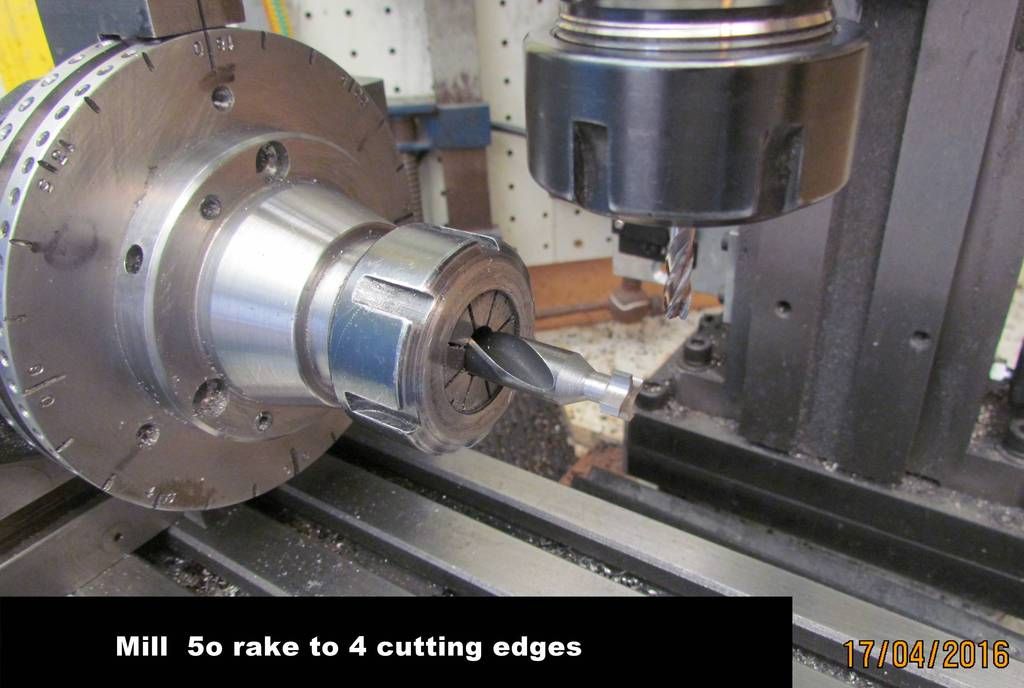

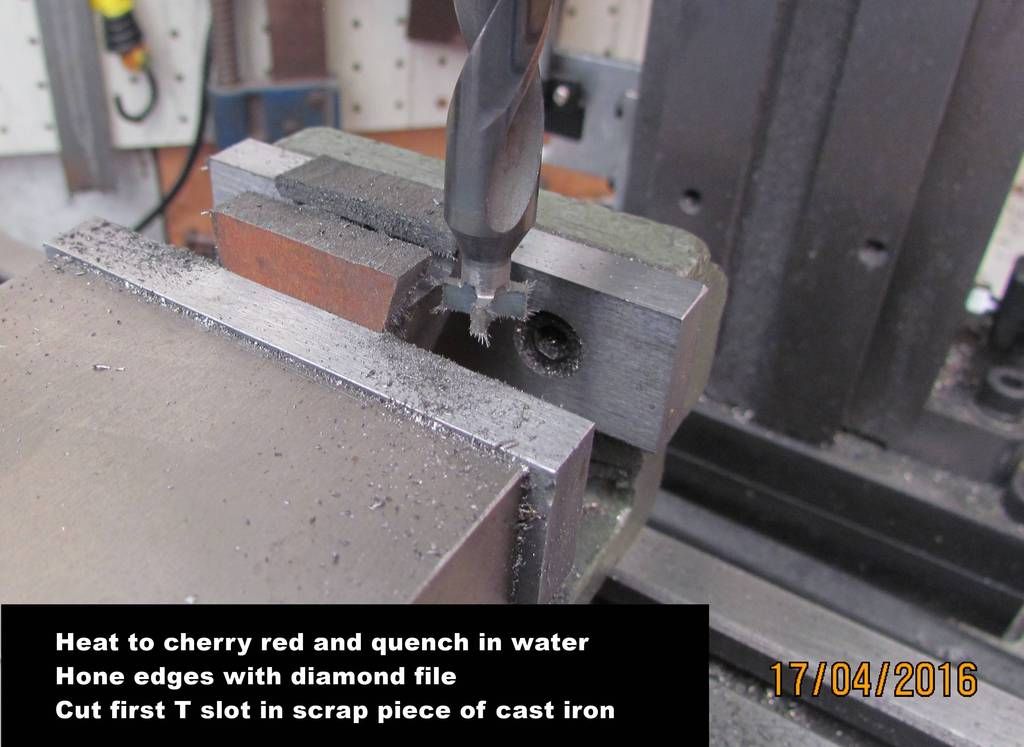

At the moment I am fabricating the table.Starting with a piece of 50x50x8 ms angle.The top of the table I wanted to use cast iron and to machine small

T slots,so decided to make a T slot cutter.My limited supply of silver steel

had nothing suitable,what I did have was a box old drills.So I turned down the shank of an 11mm drill made the cutter,hardened and ground it works better than a bought one and I can still use the drill