- Joined

- Dec 14, 2007

- Messages

- 1,181

- Reaction score

- 31

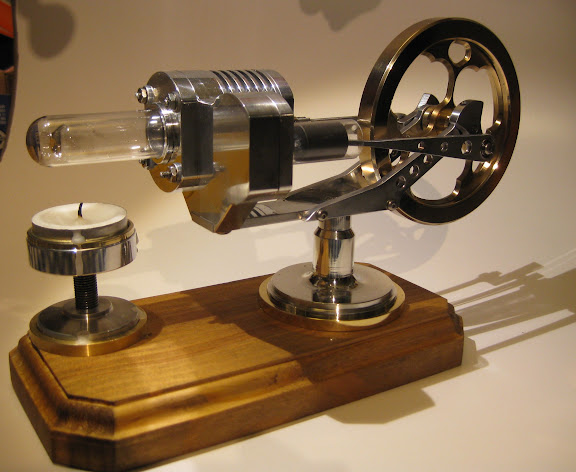

I have always wanted an engine that would run off of a tea light. Jan Ridders' "Bas" will fit the bill nicely.

I won't get any work done until the Hoglet is put to rest, but for now I just wanted to get some computer modeling practice in;

[ame]http://www.youtube.com/watch?v=9NOLnUc3QP0[/ame]

Here is Jan's finished model;

[ame]http://www.youtube.com/watch?v=VCkjdJzIXQE[/ame]

Have fun!

I won't get any work done until the Hoglet is put to rest, but for now I just wanted to get some computer modeling practice in;

[ame]http://www.youtube.com/watch?v=9NOLnUc3QP0[/ame]

Here is Jan's finished model;

[ame]http://www.youtube.com/watch?v=VCkjdJzIXQE[/ame]

Have fun!