Sshire

Well-Known Member

- Joined

- Jun 29, 2011

- Messages

- 936

- Reaction score

- 259

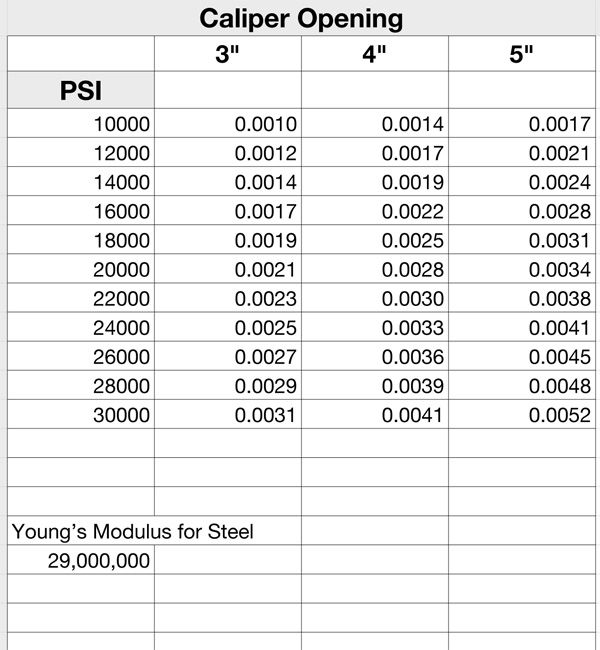

Harbor Freight Bandsaw Blade Tension Gauge

Had a few things to pick up at the market and on my way out "Oh look! Harbor Freight"

I had a coupon (that's like saying the Atlantic Ocean is wet). Even people who have no need for anything at HF and have never gone inside, have a coupon.

I had forgotten where I saw it, but there was an interesting technique for measuring the tension of bandsaw blades. It seems you open a pair of calipers to a fixed distance (makes no difference what distance as long as you know what it is. We can call it Jaw Opening), loosen the tension on the bandsaw, clamp the calipers to the blade, zero the calipers and then re-tension the blade until you get a specific reading.

It all has to do with Young's Modulus of Elasticity. (basically, how much tension stretches stuff.)

Young's Modulus for steel is 29,000,000.

Dividing that into the desired blade tension will give the amount of stretch per inch. Multiply that times the Jaw opening in inches and you know what movement you need to achieve a desired tension.

I did a quick spreadsheet.

Had a few things to pick up at the market and on my way out "Oh look! Harbor Freight"

I had a coupon (that's like saying the Atlantic Ocean is wet). Even people who have no need for anything at HF and have never gone inside, have a coupon.

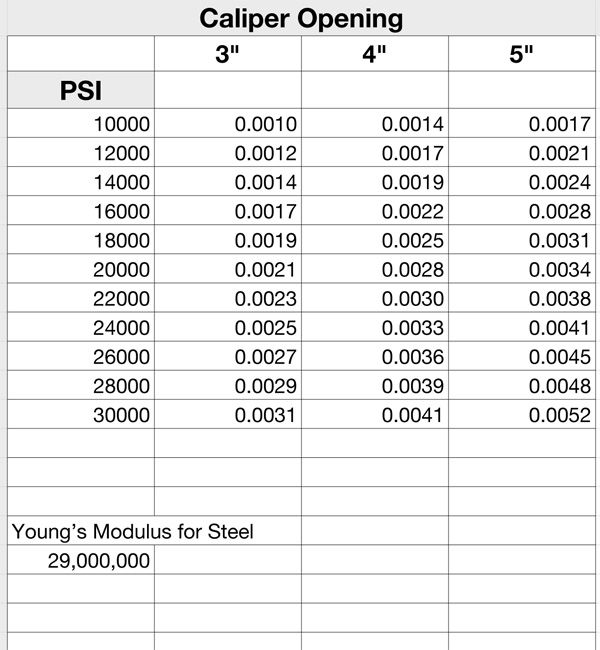

I had forgotten where I saw it, but there was an interesting technique for measuring the tension of bandsaw blades. It seems you open a pair of calipers to a fixed distance (makes no difference what distance as long as you know what it is. We can call it Jaw Opening), loosen the tension on the bandsaw, clamp the calipers to the blade, zero the calipers and then re-tension the blade until you get a specific reading.

It all has to do with Young's Modulus of Elasticity. (basically, how much tension stretches stuff.)

Young's Modulus for steel is 29,000,000.

Dividing that into the desired blade tension will give the amount of stretch per inch. Multiply that times the Jaw opening in inches and you know what movement you need to achieve a desired tension.

I did a quick spreadsheet.