Kaleb

Senior Member

- Joined

- Jan 3, 2010

- Messages

- 272

- Reaction score

- 27

I've got a drill press vice that was jamming up on me, so I took it apart to see where the problem was, and I quickly discovered just how poorly made it was. There were numerous issues.

As you can see, there is a heap of slop between the screw and the movable jaw. I've also had problems with the end of the screw popping out when it's loosened.

And here's why. The groove in the end of the screw does not line up with either of those holes. As for the jamming problem, take a close look at the bottom of this jaw. Can you see the other problem?

You guessed it, bad surface finish. Interestingly, the tool marks indicate that it was faced in a lathe rather than milled. This seems a bit unusual for a mass produced item. I'm certain of what was being done wrong, tool was being fed way too fast. I've heard of increasing feeds to get better productivity but this is ridiculous! The finish is so bad that I wonder why they even bothered machining that surface!

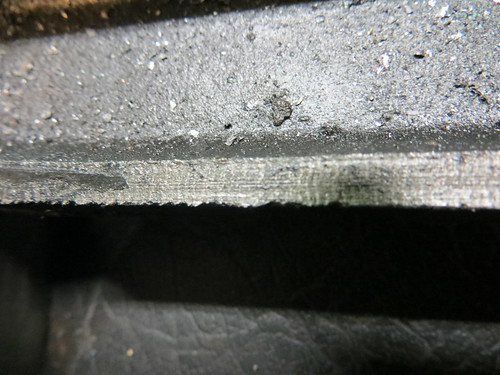

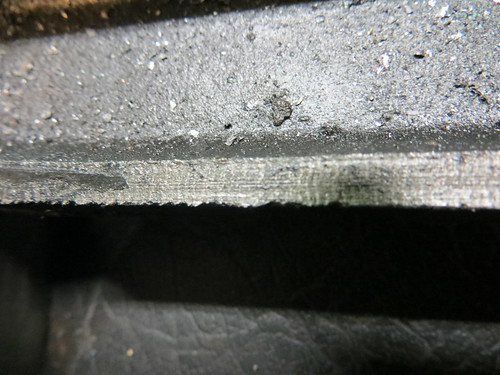

The surface where the jaw plate screws on is also pretty bad. Again, it seems the tool was fed way too fast here.

The other thing that confounds me is the variation in the quality between parts. The base of the vice looks to be a bit better done, and the screw looks a lot better made. Also the fixed jaw has definitely been milled.

But these voids make it look like a bad casting.

And the milled strips down here seem a bit poor as well.

I've started making improvements to take these flaws out where I can. However, does anyone have any ideas to explain the seemingly odd choices of machining methods, and the variation in quality, not to mention how such poor work was allowed to leave the factory?

As you can see, there is a heap of slop between the screw and the movable jaw. I've also had problems with the end of the screw popping out when it's loosened.

And here's why. The groove in the end of the screw does not line up with either of those holes. As for the jamming problem, take a close look at the bottom of this jaw. Can you see the other problem?

You guessed it, bad surface finish. Interestingly, the tool marks indicate that it was faced in a lathe rather than milled. This seems a bit unusual for a mass produced item. I'm certain of what was being done wrong, tool was being fed way too fast. I've heard of increasing feeds to get better productivity but this is ridiculous! The finish is so bad that I wonder why they even bothered machining that surface!

The surface where the jaw plate screws on is also pretty bad. Again, it seems the tool was fed way too fast here.

The other thing that confounds me is the variation in the quality between parts. The base of the vice looks to be a bit better done, and the screw looks a lot better made. Also the fixed jaw has definitely been milled.

But these voids make it look like a bad casting.

And the milled strips down here seem a bit poor as well.

I've started making improvements to take these flaws out where I can. However, does anyone have any ideas to explain the seemingly odd choices of machining methods, and the variation in quality, not to mention how such poor work was allowed to leave the factory?