- Joined

- Aug 16, 2013

- Messages

- 1,033

- Reaction score

- 764

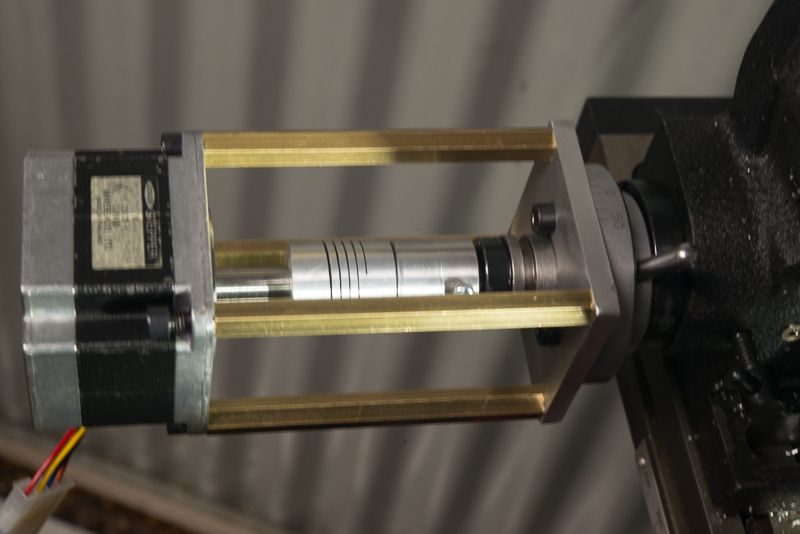

I want to be able to cut the gears, and to do that I needed an indexer or dividing head. Id looked at a lot of plans for different styles of mechanical indexers and was leaning toward A Fairly Simple Dividing Head http://www.deansphotographica.com/machining/projects/divider/dividinghead.html by Dean Williams.

Then I found Chuck Fellows 2012 thread Electronic Dividing Head using the Arduino http://www.homemodelenginemachinist.com/showthread.php?t=17896 and thought it looked like a much simpler way to go. As things worked out while looking through the surplus section at Princess Auto I found some Arduinos and shields in with the oversized TV remotes, selfie sticks and other bits of electronic detritus. Armed with my new toys I dug out and dusted off a breadboard and started trying to duplicate Chucks controller. Found a schematic for the SainSmart LCD Keypad Shield that Chuck used and after much cursing and searching for libraries I managed to get it to work. Messed around with it for a while but I just didnt like the button interface and the project want into the corner of the workshop dedicated to UFOs (Un Finished Objects).

I havent done much in the way of programing for many years but I liked the Arduino and ordered Arduino for Dummies and started going through the exercises. Back in January while looking around on the internet I found a thread on CNC Zone for a standalone CNC rotary table controller for Sherline. I liked the use of a keypad for enter as well as the 20x4 text display. Downloaded the sketch and after messing around with a few DIY worm gears I had it running but not well and it went back to the UFO corner.

[ame="https://www.youtube.com/watch?v=-hO4id64xDU"]https://www.youtube.com/watch?v=-hO4id64xDU[/ame]

Then I found Chuck Fellows 2012 thread Electronic Dividing Head using the Arduino http://www.homemodelenginemachinist.com/showthread.php?t=17896 and thought it looked like a much simpler way to go. As things worked out while looking through the surplus section at Princess Auto I found some Arduinos and shields in with the oversized TV remotes, selfie sticks and other bits of electronic detritus. Armed with my new toys I dug out and dusted off a breadboard and started trying to duplicate Chucks controller. Found a schematic for the SainSmart LCD Keypad Shield that Chuck used and after much cursing and searching for libraries I managed to get it to work. Messed around with it for a while but I just didnt like the button interface and the project want into the corner of the workshop dedicated to UFOs (Un Finished Objects).

I havent done much in the way of programing for many years but I liked the Arduino and ordered Arduino for Dummies and started going through the exercises. Back in January while looking around on the internet I found a thread on CNC Zone for a standalone CNC rotary table controller for Sherline. I liked the use of a keypad for enter as well as the 20x4 text display. Downloaded the sketch and after messing around with a few DIY worm gears I had it running but not well and it went back to the UFO corner.

[ame="https://www.youtube.com/watch?v=-hO4id64xDU"]https://www.youtube.com/watch?v=-hO4id64xDU[/ame]