You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anybody want to guess---

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Brian,

Thanks for the link and thanks for the learning experience, it looks great and again appreciate the as you go photos, hope to get me closed in shop ready by late summer when the days are 100 degrees and start some of your designs and builds, again thanks, Lathe Nut

Thanks for the link and thanks for the learning experience, it looks great and again appreciate the as you go photos, hope to get me closed in shop ready by late summer when the days are 100 degrees and start some of your designs and builds, again thanks, Lathe Nut

- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

Brian

Thanks for this very interesting build. Anyone who has not built an IC engine (that includes me) should now feel that it is within their reach. Where your builds go slightly off and you make adjustments or refinements to bring it back on course is the what inspires us all to attempt more difficult projects. It may be difficult to show the goofs but everyone here should know, that's life in the shop. Congratulations on getting it running! And getting it tuned. And showing us all how it was done! th_wav

Jerry

Thanks for this very interesting build. Anyone who has not built an IC engine (that includes me) should now feel that it is within their reach. Where your builds go slightly off and you make adjustments or refinements to bring it back on course is the what inspires us all to attempt more difficult projects. It may be difficult to show the goofs but everyone here should know, that's life in the shop. Congratulations on getting it running! And getting it tuned. And showing us all how it was done! th_wav

Jerry

putputman

Senior Member

- Joined

- Nov 22, 2008

- Messages

- 600

- Reaction score

- 55

Congratulations Brian!!!!!! :bow: :bow:

Hearing that first "pop" of the engine is always a thrill. From here on it's just a matter of fine tuning the timing and carb.

An idea you might consider. When I made my Webster, I made a small pulley that fit on the crankshaft. Put a small notch in one of the flanges and used a small diameter nylon rope with a wooden handle on it for a rope starter. Just tie a fair size knot in the rope that will hook in the flange and release after each pull. That way you can start your engine anywhere and don't need electricity.

Hearing that first "pop" of the engine is always a thrill. From here on it's just a matter of fine tuning the timing and carb.

An idea you might consider. When I made my Webster, I made a small pulley that fit on the crankshaft. Put a small notch in one of the flanges and used a small diameter nylon rope with a wooden handle on it for a rope starter. Just tie a fair size knot in the rope that will hook in the flange and release after each pull. That way you can start your engine anywhere and don't need electricity.

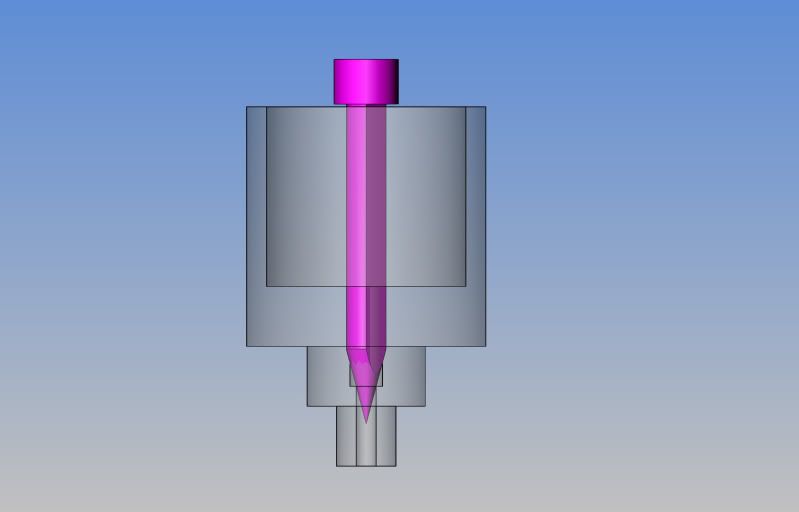

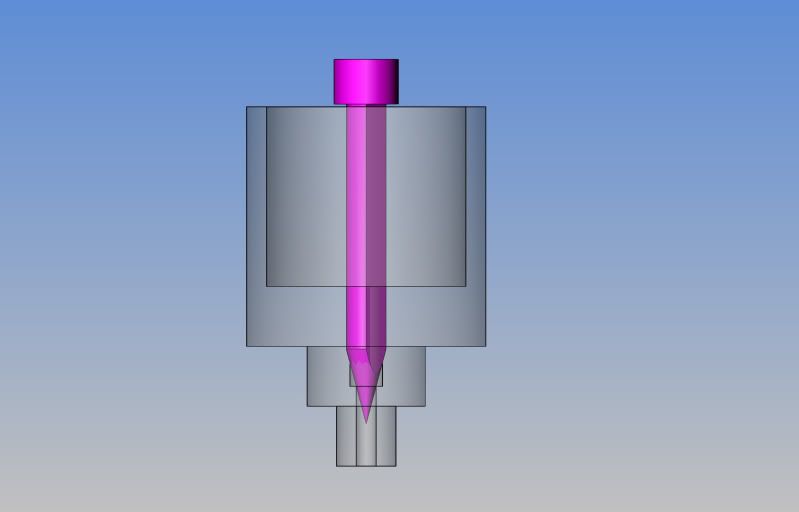

Just as I suspected, there is something wrong with the design of the large oiler that screws onto the cylinder barrel. There is an internal #4-40 thread inside the oiler, and a #4-40 screw filed to a point that screws into the oil cup to control the amount of oil flow. I looked at it and thought---Thats not going to work!!! The oil has to migrate past all of the screw threads before it even gets to the tapered point which interfaces with the .063 hole in the bottom of the oil cup. However, websters plans were good up to this point, so I made the oiler and control screw as per plan. And yep, I was right. Even with the screw loose, not seated, there is no oil flow. Now I have to come up with a fix for that.---------------That turned out to be an easy enough fix. I ground the threads flat on two opposing sides of the screw, almost full length, leaving enough thread engaging to still hold the screw in the barrel. Now the oil doesn't have to migrate past the threads--it can run down both sides of the screw where I ground the material away untill it gets to the area where the taper on the screw seals against the step on the inside of the barrel where the diameter of the bore drops to .062".

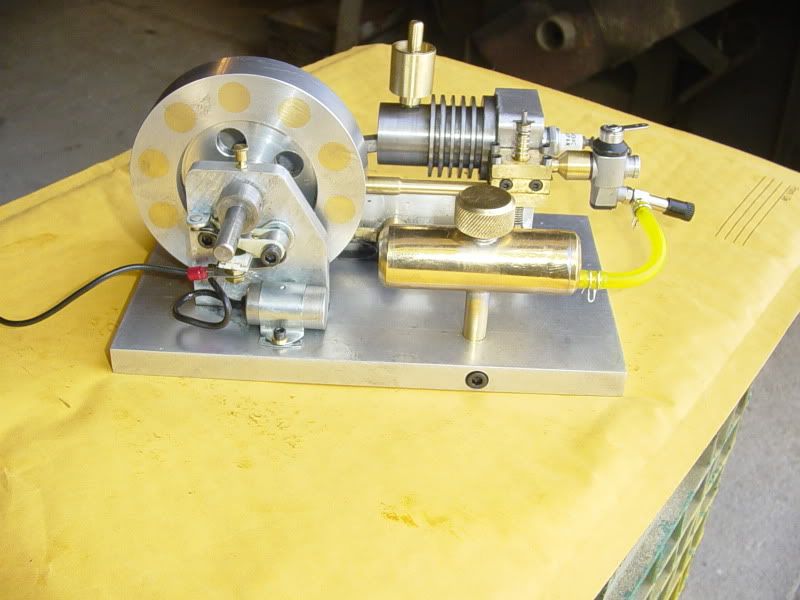

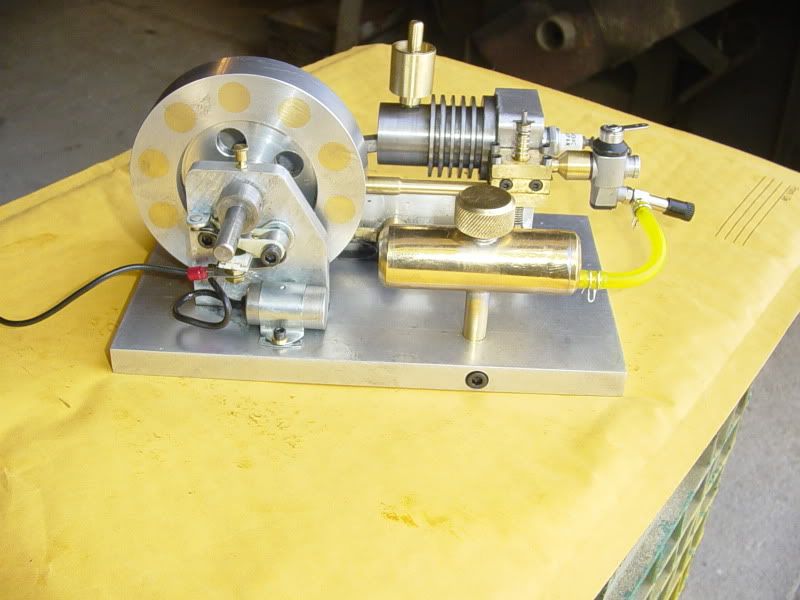

I have worked this morning dismantling the engine, cleaning it up, and adding the appropriate oil and grease cups. I am going to make a video within the hour, but I thought I would try and take at least 3 good quality still shots of the engine before I get it all dirty running it again. I have a couple of comments about this engine. #1--If you can build a small steam/air engine with no great difficulty, then you can build this engine from Websters plans. There is no level of complexity in making any of the parts for this engine that is greater than the machining found in making any of our small steam engines.

#2---This is not a cheap engine to build, even if you have all or most of the aluminum and brass bits laying around your shop.

Sparkplug---------------$20.00

Coil---------------------$50.00

Grease cups-------------$12.00

Carburetor--------------$45.00

Points and condenser----$16.00

Fuel line and clamps------$2.00

On/off switch and wire---$8.00

Gears--------------------$70.00

My battery was free, as its out of my boat, but you see what I mean---Thats a sum of $223.00 when you add it all up.

---Still, it is a great thrill for me to have built my first I.C. engine.------Brian

#2---This is not a cheap engine to build, even if you have all or most of the aluminum and brass bits laying around your shop.

Sparkplug---------------$20.00

Coil---------------------$50.00

Grease cups-------------$12.00

Carburetor--------------$45.00

Points and condenser----$16.00

Fuel line and clamps------$2.00

On/off switch and wire---$8.00

Gears--------------------$70.00

My battery was free, as its out of my boat, but you see what I mean---Thats a sum of $223.00 when you add it all up.

---Still, it is a great thrill for me to have built my first I.C. engine.------Brian

black85vette

Well-Known Member

- Joined

- Jan 18, 2009

- Messages

- 1,084

- Reaction score

- 24

Really impressive Brian. Appreciate all the thought, details and information you have put into this thread. Looking forward to the video. :bow:

Very Nice Brian,

I'm waiting on the vid too!

You kept the receipts? You never keep receipts in a hobby

You don't want to know :big:

You know that you can move that carb arm to any position you want. Loosen screw and move. You will have to hit the low or high stops then it will rotate

Tony

I'm waiting on the vid too!

You kept the receipts? You never keep receipts in a hobby

You don't want to know :big:

You know that you can move that carb arm to any position you want. Loosen screw and move. You will have to hit the low or high stops then it will rotate

Tony

congrats Brian on your first (and very well running!) IC engine :bow:

I envy your success on this build, because my first IC engine didn't run at all

occasionally I try to change some piece or setting to do a new test, but till now all the attempts have failed :-\

yours is a great engine [EDIT] and maybe that I adopt the idea of using a groove on the piston with an o-ring in it, hoping to solve my problems :

I envy your success on this build, because my first IC engine didn't run at all

occasionally I try to change some piece or setting to do a new test, but till now all the attempts have failed :-\

yours is a great engine [EDIT] and maybe that I adopt the idea of using a groove on the piston with an o-ring in it, hoping to solve my problems :

Hi, Brian. That is a fine engine you made there. :bow: :bow: I was wondering how low can you go on your idle speed? I have downloaded his plans and may build this for my first IC engine. I think I would like to try the propane fuel system by howell and the hall effect ignition as well. I would like to have an idle speed that is slow if possible. Do you think this would work ?

Best Regards skeeter ;D

Best Regards skeeter ;D

As promised, here is the video. This will answer some of the questions about idle speeds. I had to start the engine first, then take the video, as I'm here by myself and I don't seem to have enough arms and legs to start the engine while taking the video. Hope you like it. (I have no idea where the strange alien sound effects are coming from--the batteries were a bit low in my camera.)----Brian

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Congratulations Brian.

Gets me thinking about an IC engine too.

Thanks for posting.

Gets me thinking about an IC engine too.

Thanks for posting.

My thoughts---Well, with this i.c. engine at least, its a heck of a lot messier than an "air " engine. Are they harder to build than an air/steam engine?---Not at all. They cost more to build, but only because of the peripheral equipment they require i.e. carb, coil, points, sparkplug, etc. I am thrilled that in the course of 3 years I have went from a non machinist to someone capable of building an actual running i.c. engine. Will I build another.---Heck, I don't have a clue.

NEWS FLASH: "A new WEBSTER engine is on line and has been declared "A Runner" by its fans".......... Good job Brian and your log speaks well to relative newbies, the Webster being my 1st I/C engine too. Hope you add to the You Tube collection of Websters with a good video. Can't wait to see who here is gonna jump in on this novice ability gem...............cuzz you know someone will! Thm: Dave.

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

you need a gasket Hope Ms Tin in did not write unobtainium sheet on the customs slip LOL

Tin

Tin

Similar threads

- Replies

- 13

- Views

- 593