kf2qd

Well-Known Member

- Joined

- Apr 1, 2008

- Messages

- 586

- Reaction score

- 76

I have a Hardinge UM from an old Navy vessel that is missing the power feed. I have an idea of the size to the worm wheel and wor.

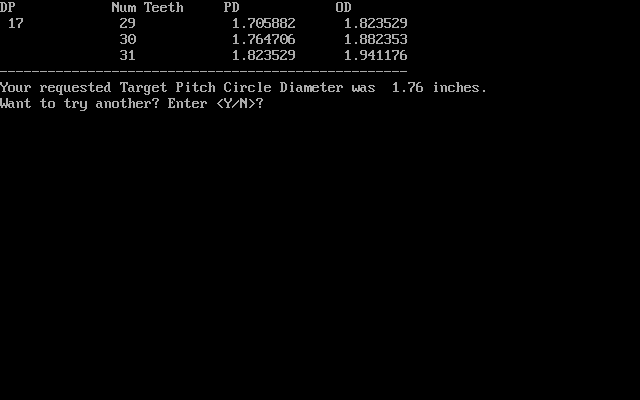

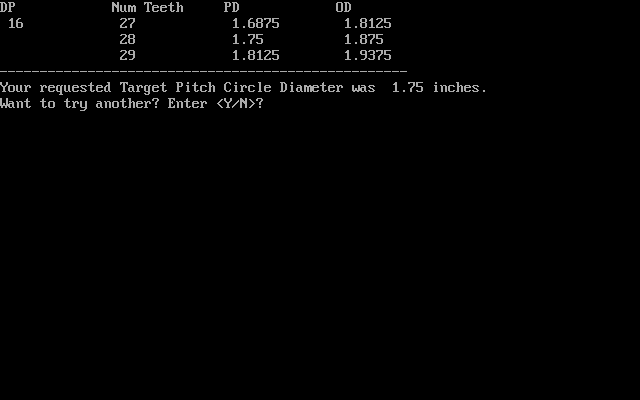

It would appear that the original had a 2 start worm and 30 tooth wheel. Bore on the worm was 5/8 and fit over the table lead screw with a key driving the screw.

It would appear from the pictures I have seen that the OD of the wheel was about 1-7/8and the worm about 1-1/4.

Any thoughts or ideas?

KF2QD

Pete

It would appear that the original had a 2 start worm and 30 tooth wheel. Bore on the worm was 5/8 and fit over the table lead screw with a key driving the screw.

It would appear from the pictures I have seen that the OD of the wheel was about 1-7/8and the worm about 1-1/4.

Any thoughts or ideas?

KF2QD

Pete