Hi Bob !

What does the "C" at the end mean ?

The number 1 and the C get pronounced as "once".

Hi Bob !

What does the "C" at the end mean ?

Hi !

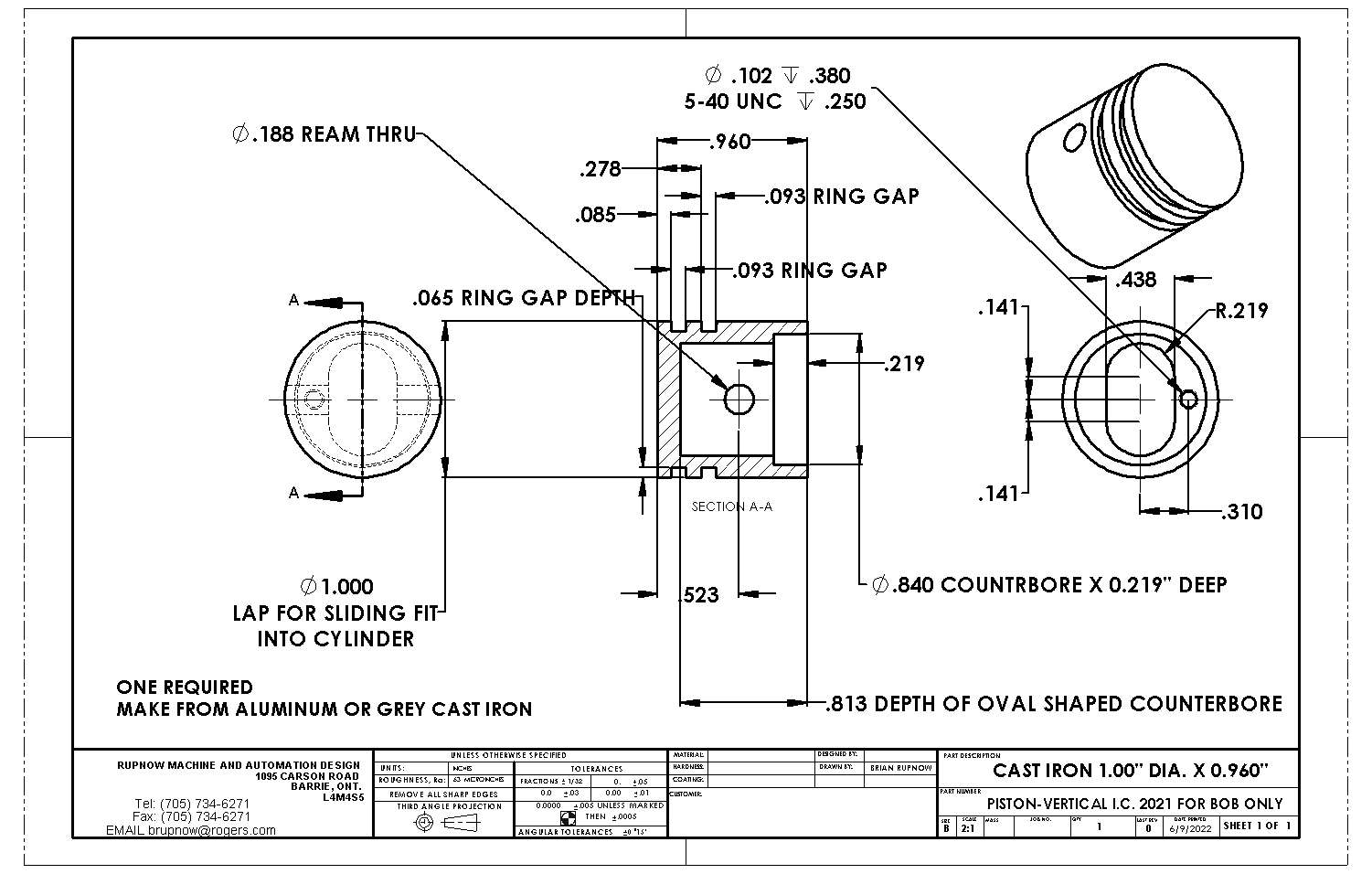

If you use a cast iron ring , one ring is not a problem .

Some of my engines have pistons without rings and they still run, so don't worry too much about a ring or two.

If you want two rings, a distance of about 1.5 - 1.8 is fine

the piston you made is only for Viton o-rings.

Sorry Bob--I never seen that email. I just talked to Hercules O-rings here in Barrie, and the o-rings are brown in color and have a 75 durometer hardness. They sell for 60 cents each, and you only need one o-ring on the cylinder.

Or you could buy 50 of part #5267T83 for $19.26 from McMaster-Carr

Or you could buy 50 of part #5267T83 for $19.26 from McMaster-Carr

Good start on the crank, This what i use

https://littlemachineshop.com/products/product_view.php?ProductID=4464

Sounds like serious no fun.Is thing still on? Tap... Tap...

To make a long story short, I'm going to not say much, but it has been a rough year for me. It started with my cat having some issues that have had him on medication every day since last March, and going to the vet every few weeks. Then it was my turn for some medical issues around the time of the last posts, and I'm in a waiting queue for a "minor" surgery in the next few weeks. Add in relatively minor damage from hurricane/tropical storm Ian that really decimated southwest Florida then went west of me there have been distinctly unpleasant things keeping me out of the shop.

However, since life has more or less stabilized, I was able to finish adding the piston ring grooves last talked about and I'm refreshing myself on what I was doing and what is planned.

The hurricane damage is going to involve some almost construction-level work that I'll need my machine tools for (repairing my ham radio tower) and some delays there, too. I won't be able to do anything strenuous after the surgery, so I have no idea how long things will remain unsettled.

Enter your email address to join: