rake60

Well-Known Member

- Joined

- Jul 8, 2007

- Messages

- 4,756

- Reaction score

- 124

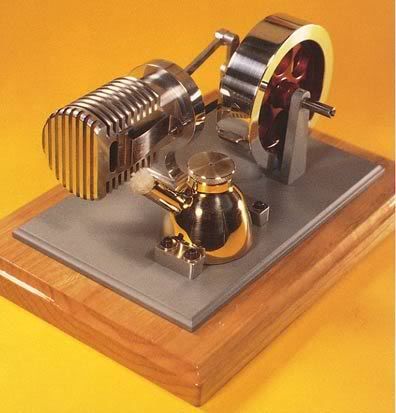

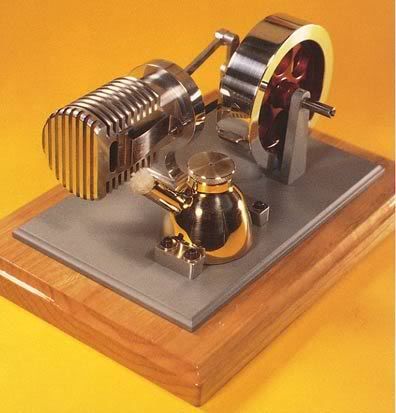

I've seen pictures of this Flame Licker design a few places and I've been

searching for the plans.

It seems a young man re-drew the plan as a high school drafting project.

He posted his work on his web site at:

http://www.anthonydavies.org/inv1.html

Another one on the things to build list.......

searching for the plans.

It seems a young man re-drew the plan as a high school drafting project.

He posted his work on his web site at:

http://www.anthonydavies.org/inv1.html

Another one on the things to build list.......