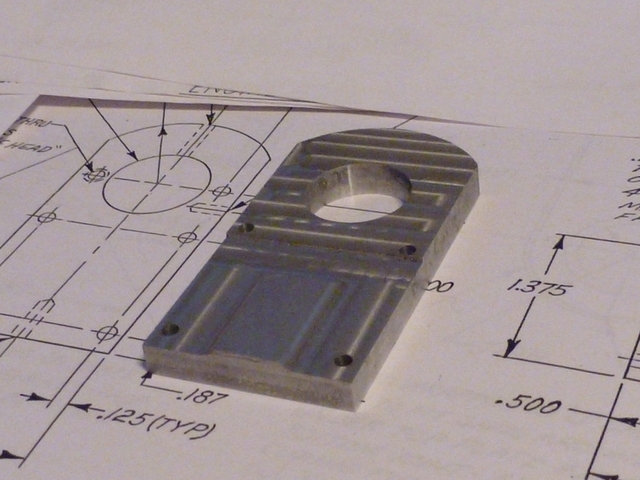

With a couple of steam engines under my belt, I've been wanting to build an

internal combustion type. I did some research and read some build logs here,

and it finally came down to Jerry Howell's Farm Boy or one of the Upshur farm

engines. After obtaining the plans, I really liked the Farm Boy, and I even

built a rocker arm and rocker arm post for it before the Upshur plans arrived.

After studying these, I decided to do a horizontal water-cooled Upshur farm

engine instead, as it seemed simpler to build.

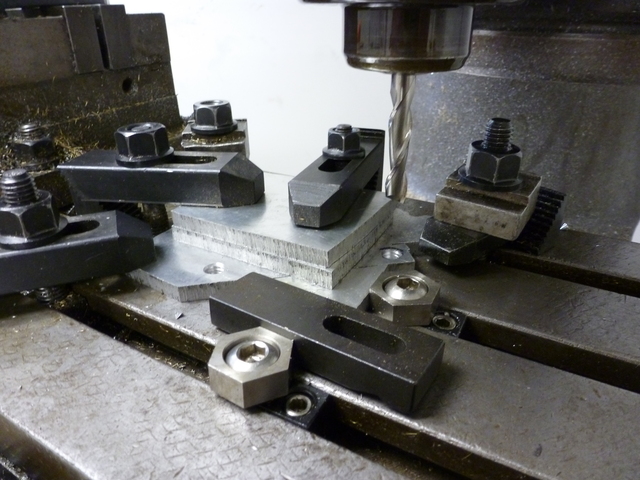

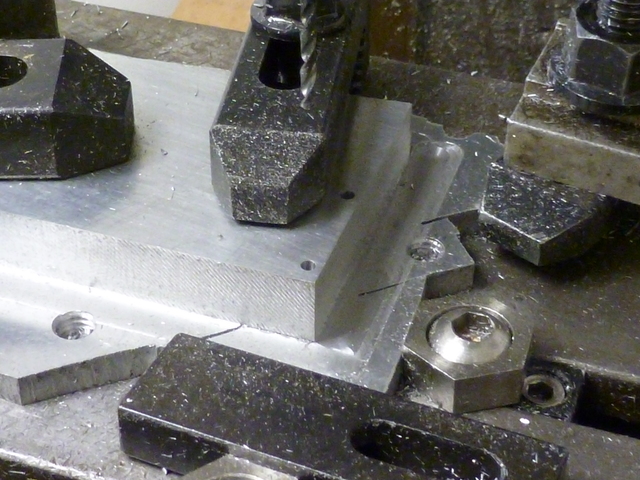

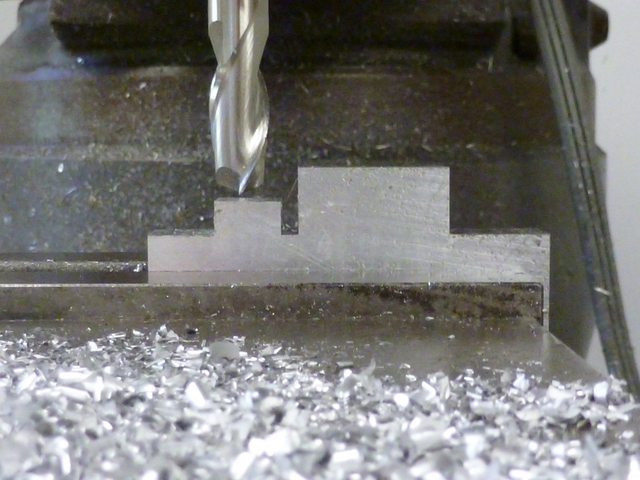

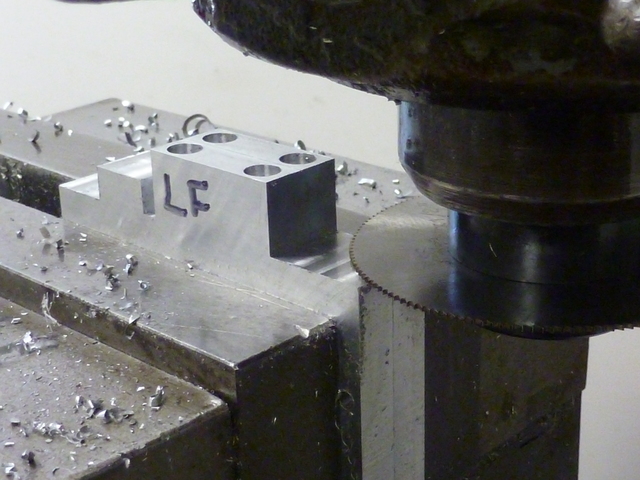

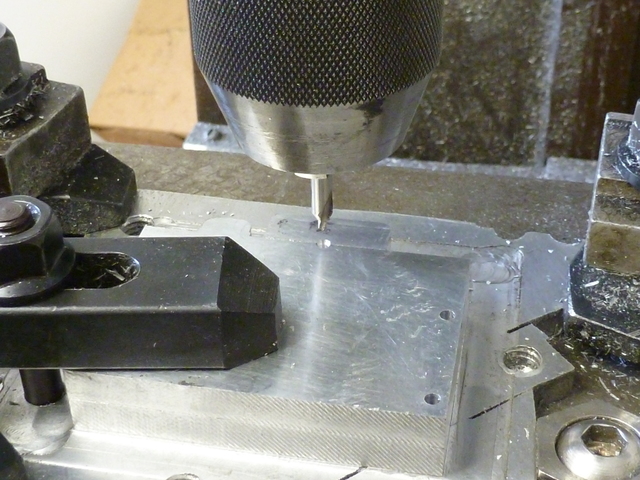

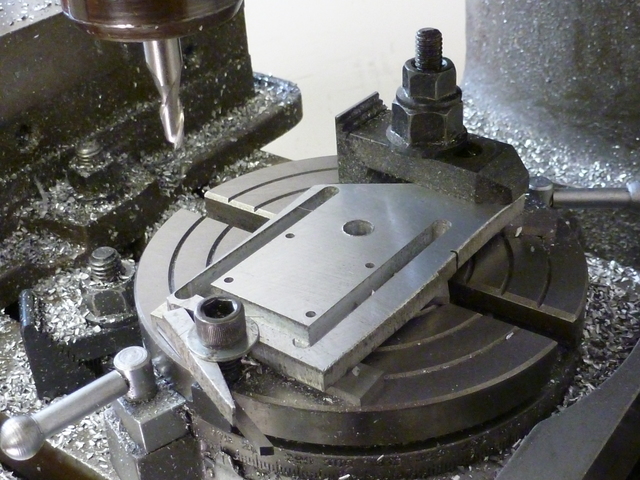

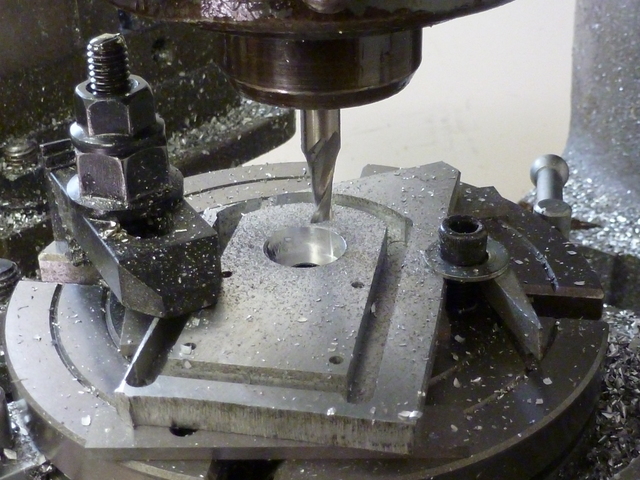

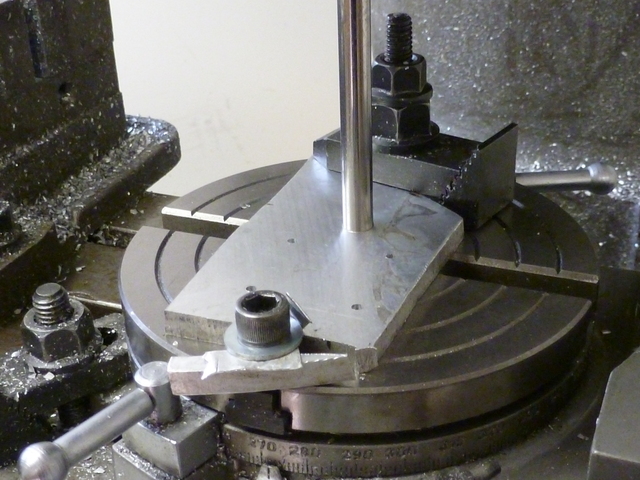

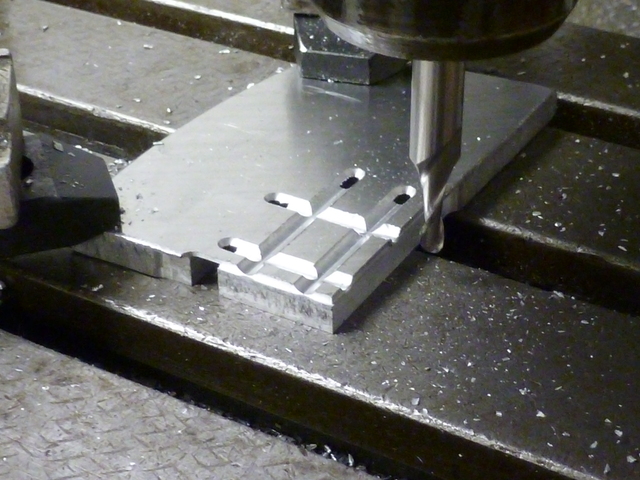

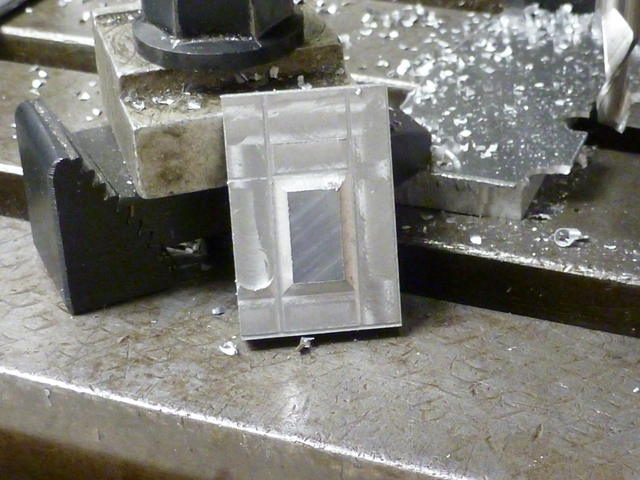

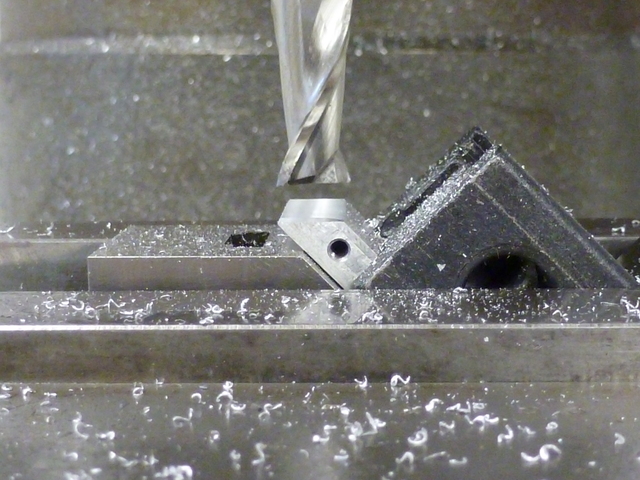

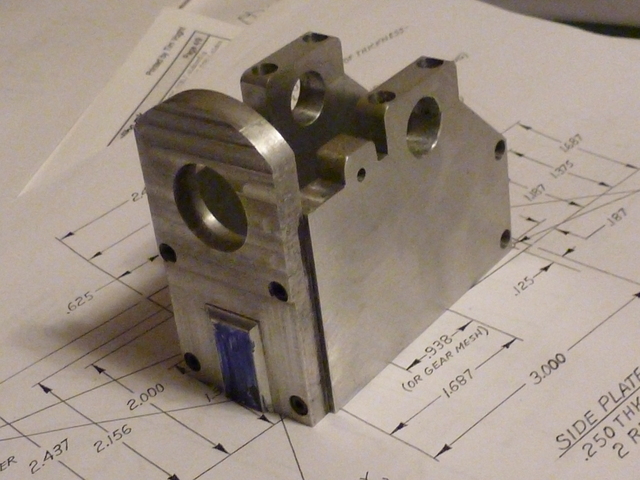

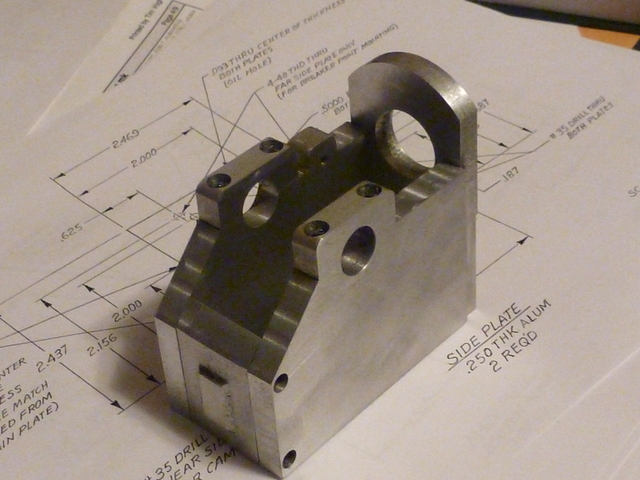

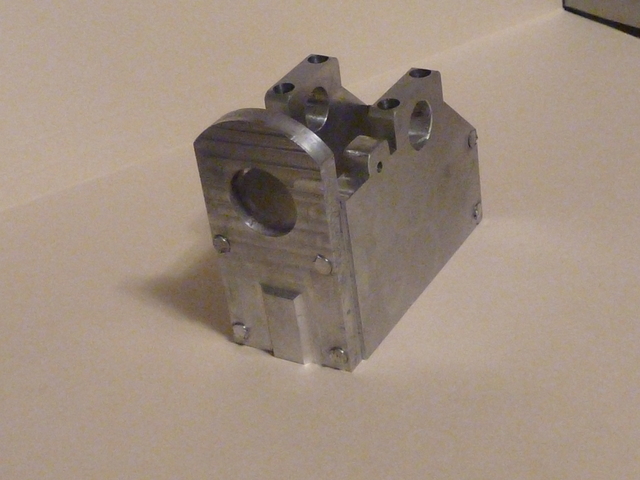

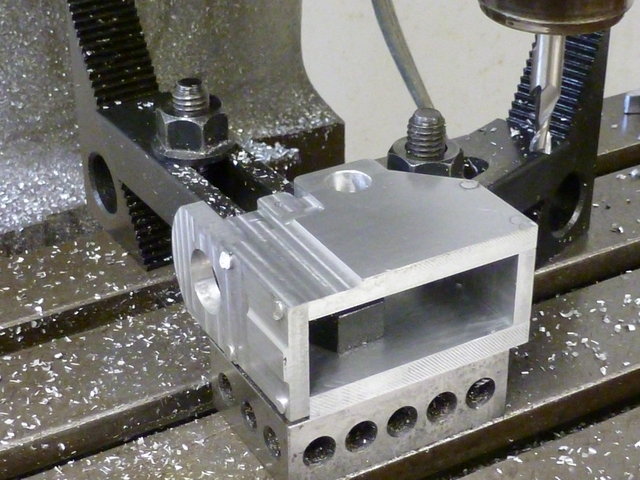

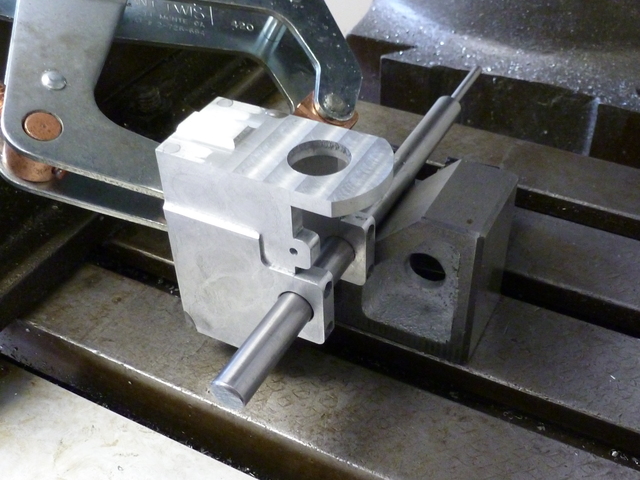

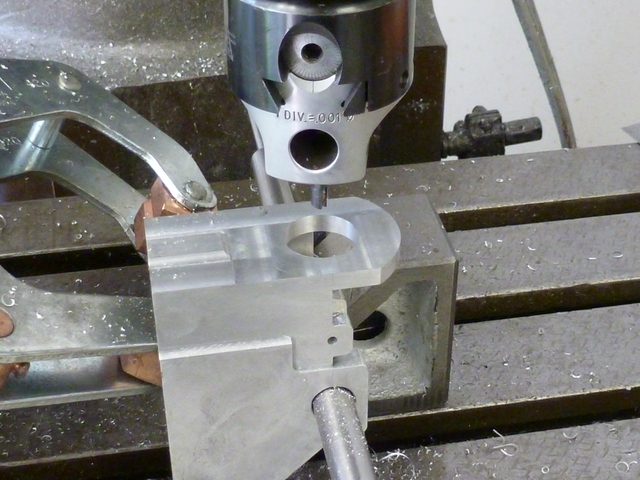

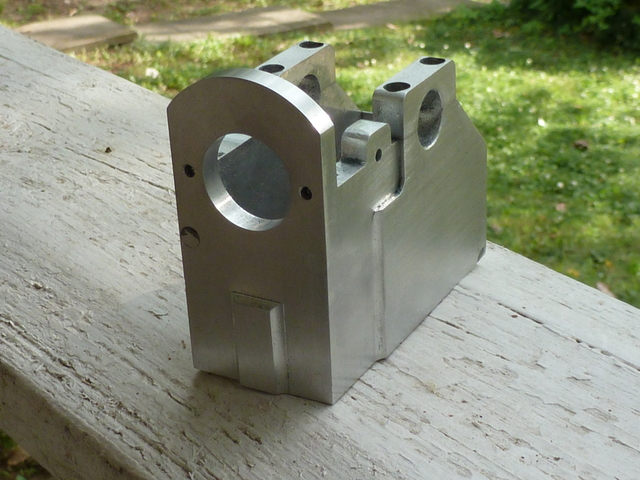

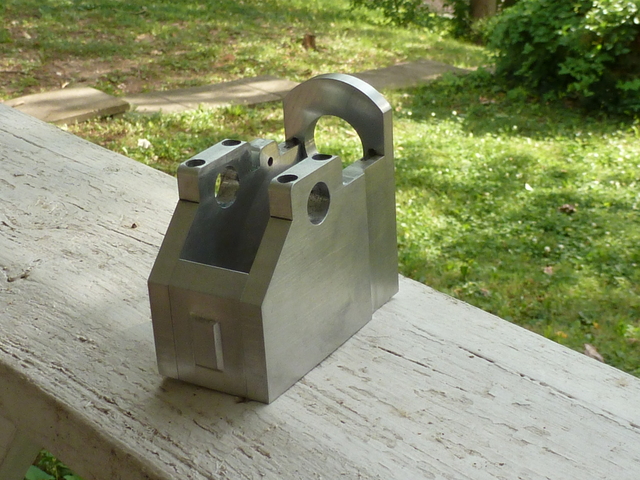

I'm starting this log after having completed enough to have the confidence to

continue, so I'll be starting with a short burst of accumulated photos.

I make no claims to having photography skills, and if a photo is poorly

focused, I included it because I thought it essential to the story.

I welcome any and all criticism. I'm here to learn.

internal combustion type. I did some research and read some build logs here,

and it finally came down to Jerry Howell's Farm Boy or one of the Upshur farm

engines. After obtaining the plans, I really liked the Farm Boy, and I even

built a rocker arm and rocker arm post for it before the Upshur plans arrived.

After studying these, I decided to do a horizontal water-cooled Upshur farm

engine instead, as it seemed simpler to build.

I'm starting this log after having completed enough to have the confidence to

continue, so I'll be starting with a short burst of accumulated photos.

I make no claims to having photography skills, and if a photo is poorly

focused, I included it because I thought it essential to the story.

I welcome any and all criticism. I'm here to learn.