J

JorgensenSteam

Guest

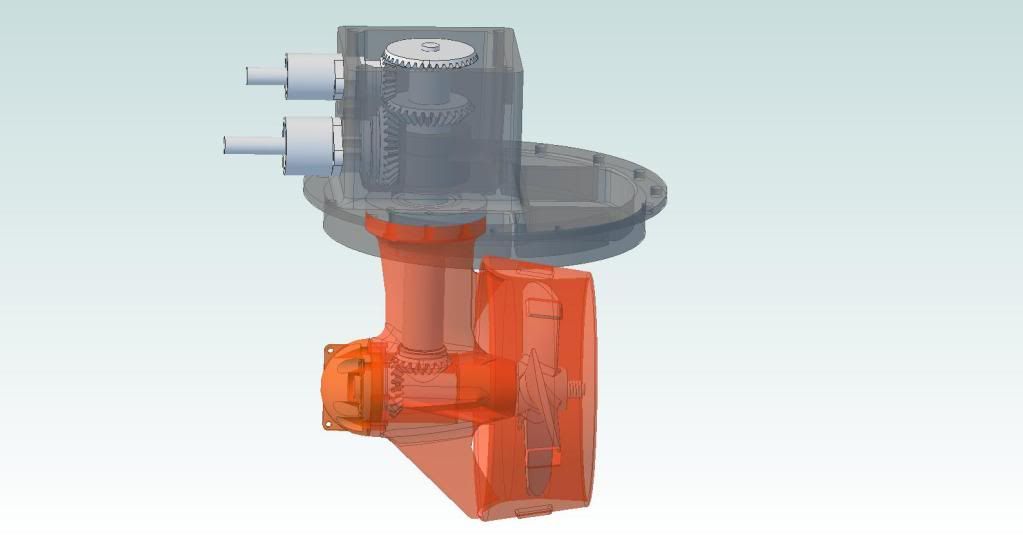

Assemblies are easy, not much trouble there.

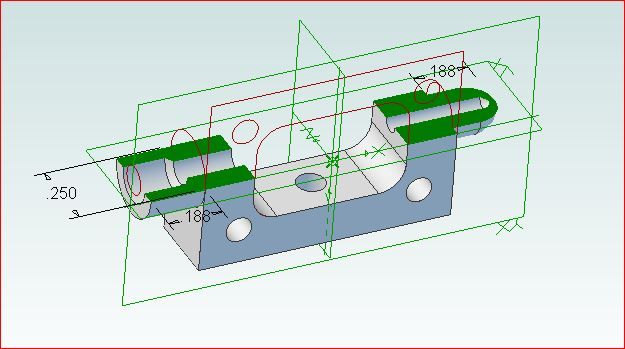

Oh I thought of that one pat but by the time I found the save as button(under the jewel) I had figured out how to edit sketches and extrude parameters.As a work-around, I would make a sketch, extrude it, and then save it as "File-01". Then make a second sketch, extrude it, then save as "File-02", etc. A new file for every added sketch/feature. Then when I botched the part, I would just open the previous file, and try it again.

Enter your email address to join: