You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AL320G and HXX GCS900-3D - Lathe DRO Setup

- Thread starter joco-nz

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

joco-nz

Well-Known Member

- Joined

- Feb 21, 2016

- Messages

- 566

- Reaction score

- 209

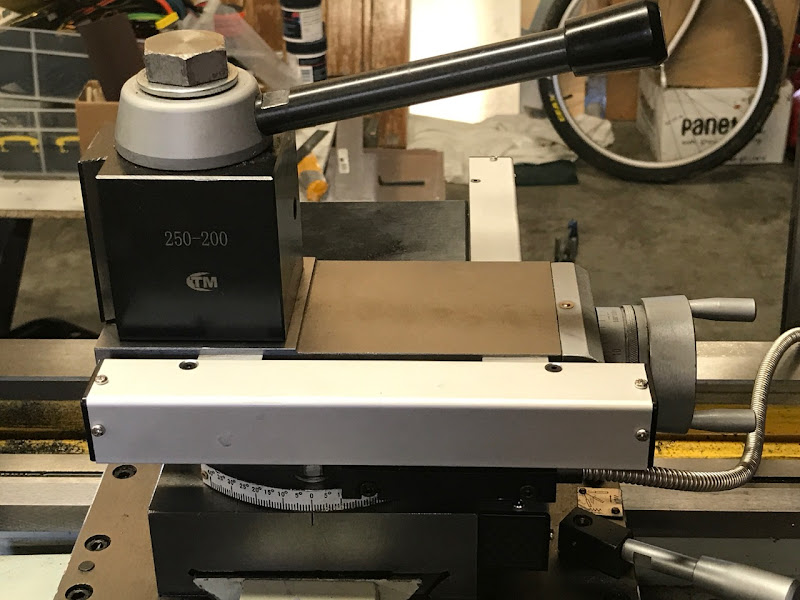

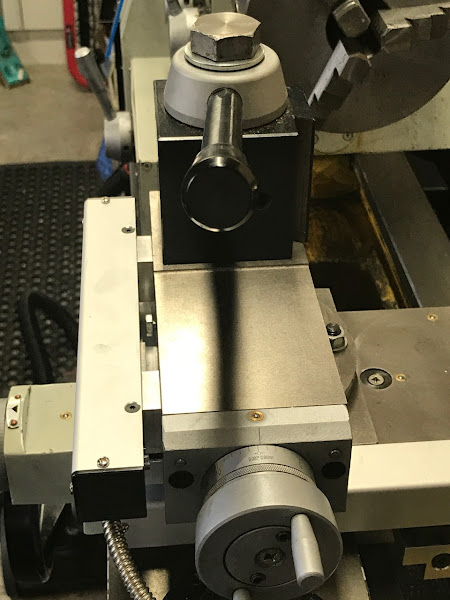

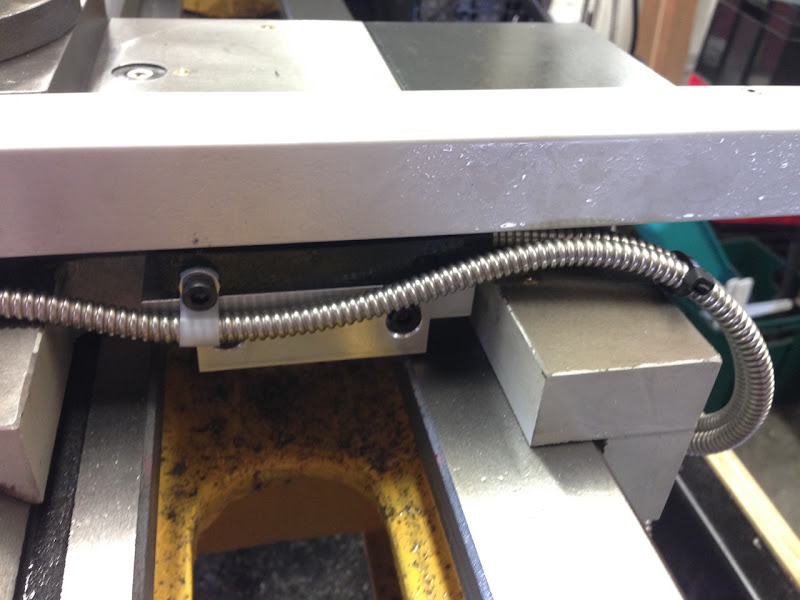

The top-slide (aka Compound) is done. I replaced the locking cap screw with a hex nut and the gap created by the stand-offs is sized to comfortably to put a 10mm spanner down to tighten the locking nut.

Next steps will be making all the cables tidy and controlled.

Cheers,

J.

Next steps will be making all the cables tidy and controlled.

Cheers,

J.

joco-nz

Well-Known Member

- Joined

- Feb 21, 2016

- Messages

- 566

- Reaction score

- 209

Nice work !

Now that has inspired me to fit the 3rd axis to my compound , i got this with the lathe but never really though about how to fit it .

Ian.

Thanks Ian. Im feeling pretty pleased with how its turning out.

joco-nz

Well-Known Member

- Joined

- Feb 21, 2016

- Messages

- 566

- Reaction score

- 209

This post is a little retrospective on the DRO display I purchased. So lets be up for front, I was doing this on a budget so cost was a big driver. The HXX DRO was a very good contender on that front. Also a mate has one and from all accounts its doing the business for him. So on that basis it was as good an option as any to go with.

When I got it the manual was bluntly wrong re the keyy needed to access the setup menu and then the manual was completely missing the config info. Hence why I created the videos I did.

I had initial trouble with some keys not working. Eg 1,2,3, divide and a Z-zeroing. However after lots of mucking about with setup menus these started to work. Cool.

This was a temporary situation. They soon stopped working period. So engaged in further discussion with the supplier an HXX factory store on AliExpress. I had already been asking questions on the setup front and politely pointing out some errors/omissions in the manual. So to head off any confusion in the opening we have a problem Houston message I provided a clear picture with annotations showing the keys that didnt work. I also did a video so that there was NO possible ambiguity and sent this to the contact I had already being dealing with.

Now you are probably thinking heres the punch line where its all going to go wrong. Well no, Im going to buck the internet trend we all seem to see on so much social media and provide praise.

Scenery Lou at HXX asked only a couple of reasonable questions and without me even prompting for it in any shape or form offered to ship a replacement unit. Honestly I have had more hassle getting warranty honored by local suppliers than this. Very happy and pleased at the customer focus, especially since its not a bulk order with a large buyer. More over the replacement came via DHL and was delivered within 3 days of shipping out of Malaysia! Now in all cases this experience depends on who you deal with, hence why I call out the individual not just the company. Although company policy/rules clearly support such behavior.

The upshot being I have a new unit installed, its working beautifully. Fingers crossed it holds. Like any electronic unit they tend to fail fast or last close to forever if looked after.

A bit of a ramble but perhaps interesting and a reminder to us that customer service is still alive and well even via the faceless medium of the internet and offshore buying/selling.

Cheers,

James.

When I got it the manual was bluntly wrong re the keyy needed to access the setup menu and then the manual was completely missing the config info. Hence why I created the videos I did.

I had initial trouble with some keys not working. Eg 1,2,3, divide and a Z-zeroing. However after lots of mucking about with setup menus these started to work. Cool.

This was a temporary situation. They soon stopped working period. So engaged in further discussion with the supplier an HXX factory store on AliExpress. I had already been asking questions on the setup front and politely pointing out some errors/omissions in the manual. So to head off any confusion in the opening we have a problem Houston message I provided a clear picture with annotations showing the keys that didnt work. I also did a video so that there was NO possible ambiguity and sent this to the contact I had already being dealing with.

Now you are probably thinking heres the punch line where its all going to go wrong. Well no, Im going to buck the internet trend we all seem to see on so much social media and provide praise.

Scenery Lou at HXX asked only a couple of reasonable questions and without me even prompting for it in any shape or form offered to ship a replacement unit. Honestly I have had more hassle getting warranty honored by local suppliers than this. Very happy and pleased at the customer focus, especially since its not a bulk order with a large buyer. More over the replacement came via DHL and was delivered within 3 days of shipping out of Malaysia! Now in all cases this experience depends on who you deal with, hence why I call out the individual not just the company. Although company policy/rules clearly support such behavior.

The upshot being I have a new unit installed, its working beautifully. Fingers crossed it holds. Like any electronic unit they tend to fail fast or last close to forever if looked after.

A bit of a ramble but perhaps interesting and a reminder to us that customer service is still alive and well even via the faceless medium of the internet and offshore buying/selling.

Cheers,

James.

joco-nz

Well-Known Member

- Joined

- Feb 21, 2016

- Messages

- 566

- Reaction score

- 209

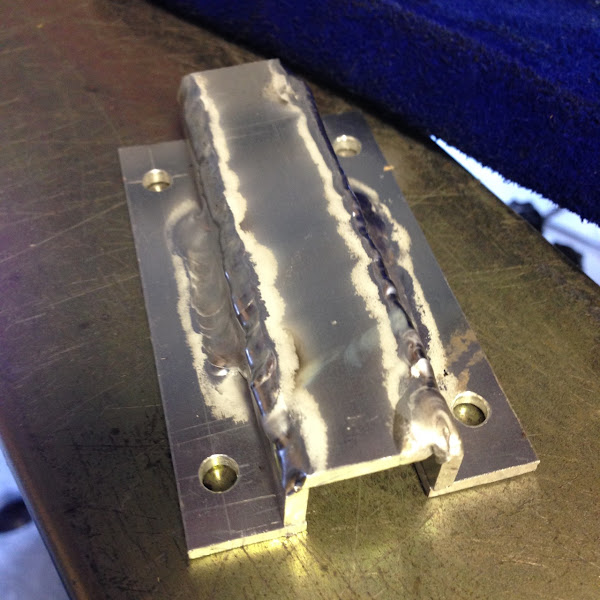

I wanted to have a way to clamp/sinch all the cables on the back of the saddle plate. So having a feeling for some welding with Ali and also needing to get as much practice as I can I made a simple clamp. Used 3mm 5005. The welds are a bit ragged, I'm really in need of a lot more practice.

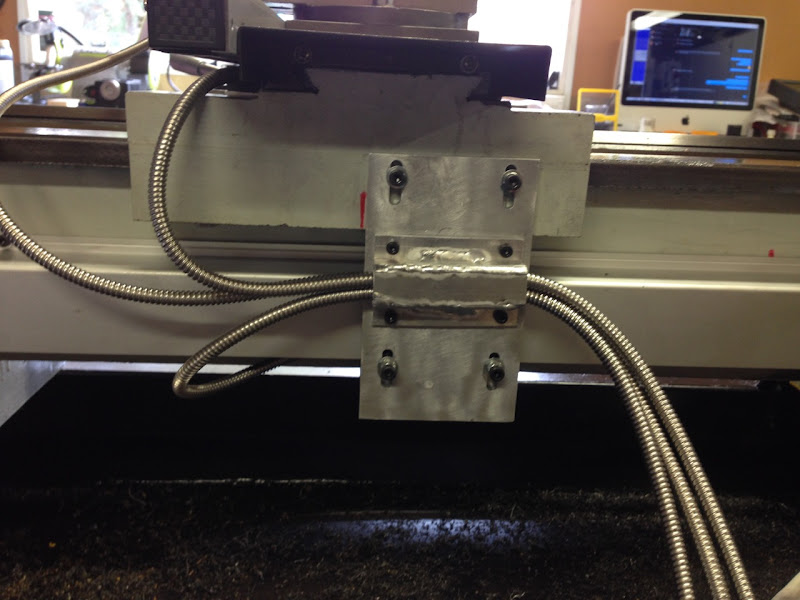

The result welded up and in use.

Holding the compound cable by using one of the threaded holes on the scale reader. Then cable tied to the cross slides cable.

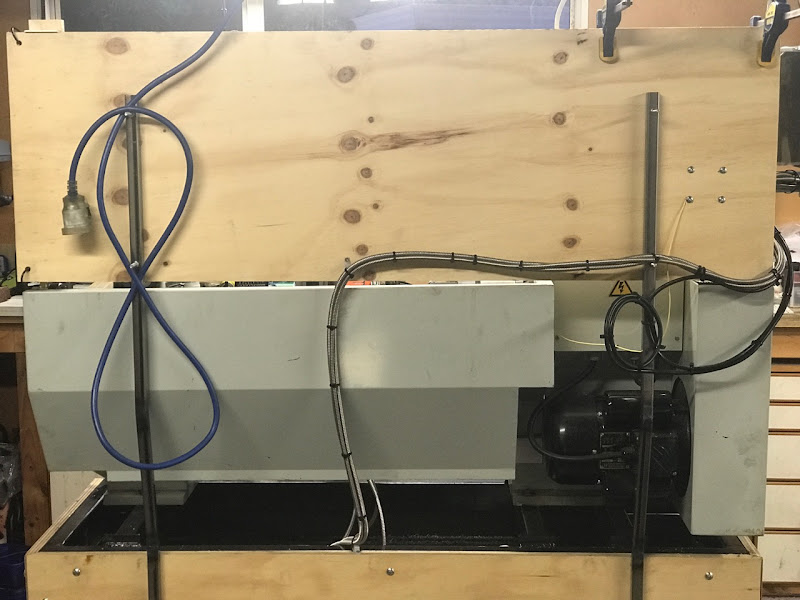

Cabling up to the DRO display and all cable tied up.

Back shot showing final cable arrangement.

Pretty pleased with the final result, especially since this sort of stuff is not a strength.

Cheers,

James.

The result welded up and in use.

Holding the compound cable by using one of the threaded holes on the scale reader. Then cable tied to the cross slides cable.

Cabling up to the DRO display and all cable tied up.

Back shot showing final cable arrangement.

Pretty pleased with the final result, especially since this sort of stuff is not a strength.

Cheers,

James.

May i suggest a couple of youtube channels to help you with welding ?

Weld.com

Welding tips and tricks .

Looking at your weld and by the amount of oxide next to the weld i would say you didn't clean it properly and really had to bludgeon it to death to get a weld pool going .

If you go to your local BOC outlet you should be able to buy a little slide rule setting gauge that will give you basic set up info , i have one and it only cost a few bucks but gives a base line to start from .

Ian

Weld.com

Welding tips and tricks .

Looking at your weld and by the amount of oxide next to the weld i would say you didn't clean it properly and really had to bludgeon it to death to get a weld pool going .

If you go to your local BOC outlet you should be able to buy a little slide rule setting gauge that will give you basic set up info , i have one and it only cost a few bucks but gives a base line to start from .

Ian

Nick Hulme

Well-Known Member

- Joined

- Oct 6, 2008

- Messages

- 338

- Reaction score

- 84

While a little mind bending (for me at least) the lathe's long axis (that which the saddle travels on) is considered Z or more correctly Z1 and the cross slide is X. Cool..

Convention has Z as the axis moving parallel to the spindle axis, with X and Y on a plane at right angles to that axis, if you had a vertical slide that would be Y

joco-nz

Well-Known Member

- Joined

- Feb 21, 2016

- Messages

- 566

- Reaction score

- 209

May i suggest a couple of youtube channels to help you with welding ?

Weld.com

Welding tips and tricks .

Looking at your weld and by the amount of oxide next to the weld i would say you didn't clean it properly and really had to bludgeon it to death to get a weld pool going .

If you go to your local BOC outlet you should be able to buy a little slide rule setting gauge that will give you basic set up info , i have one and it only cost a few bucks but gives a base line to start from .

Ian

I thought i had cleaned it ok. Its new shiny sheet, acetone cleaned. TIG welded with 80/20 balance using a foot pedal for control. Oh well, live and learn. :thumbup:

No you have to hit it with a clean stainless steel wire brush right before you weld it as alloy builds up an oxide layer , this layer re- forms again immediately after you wire brush it but it is microscopically thin so the ac can deal with it . The older the piece is the thicker the oxide will be .

With alloy when you think you have cleaned it enough clean it again , even when you stop welding a piece to get another filler rod give the piece a wire brush , it is also good practice to give the filler rod a light scrub with some clean stainless steel wool right before you start to weld .

With old alloy i use a flap disc on a grinder or a roloc scotchbright disc to clean it then back to the wire brush right before i weld .

With alloy when you think you have cleaned it enough clean it again , even when you stop welding a piece to get another filler rod give the piece a wire brush , it is also good practice to give the filler rod a light scrub with some clean stainless steel wool right before you start to weld .

With old alloy i use a flap disc on a grinder or a roloc scotchbright disc to clean it then back to the wire brush right before i weld .

Similar threads

- Replies

- 9

- Views

- 8K