BobWarfield

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 1,151

- Reaction score

- 1

One of the things I love about my newly CNC'd mill is that I can do a thing or two while it chugs away on a part. It's no wonder the pro CNC shops always look so clean!

In any event, I had a couple hours in the shop Sunday, so I decided to try my hand at vibratory deburring. A machinist friend/mentor had been after me to give it a shot after taking a look at some of my first CNC'd parts. Since it is another process that doesn't take much supervision once underway, I decided to have a go at it.

He recommended some media to use with the 6061 aluminum I've been cutting. It consists basically of little plastic triangles. That and some water were all that is needed. You can add a little polishing soap if you have a lot of parts and it will go better.

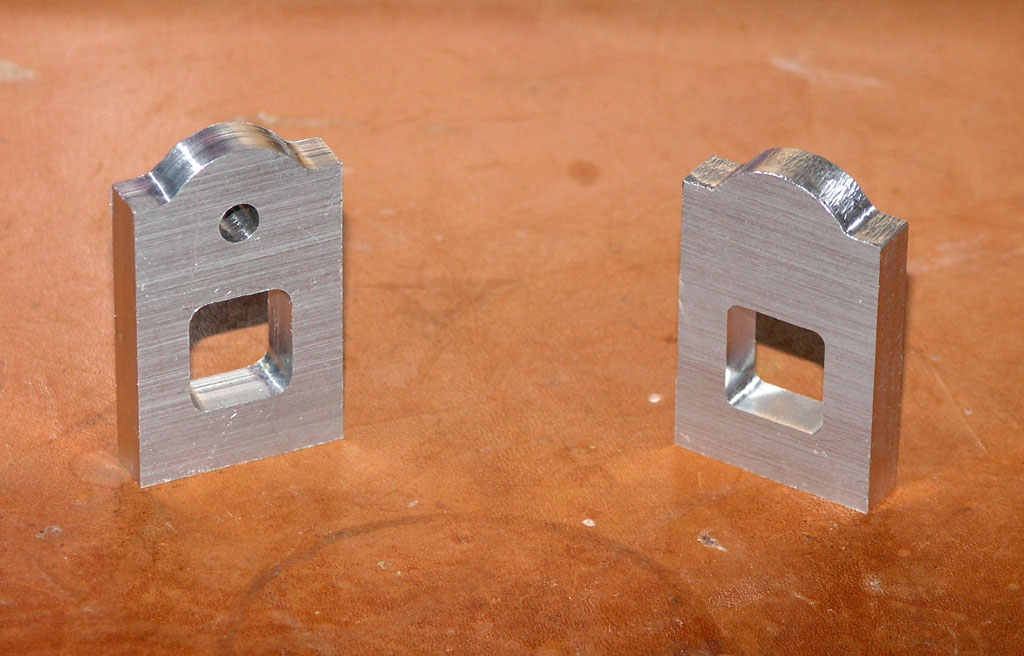

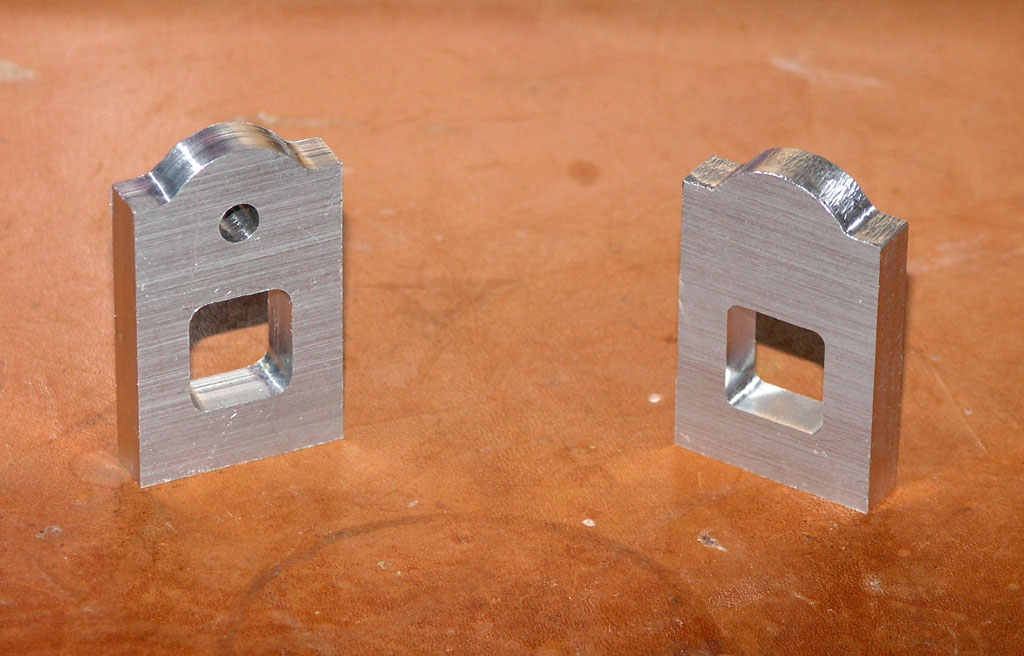

Here is my before shot:

Quite a few tooling marks and sharp edges, especially on the part at right where I was using a dull endmill, LOL!

I grabbed a handfull of these little parts (mostly mistakes, I'm still learning the CNC), tossed them into the tumbler, and went on about my business.

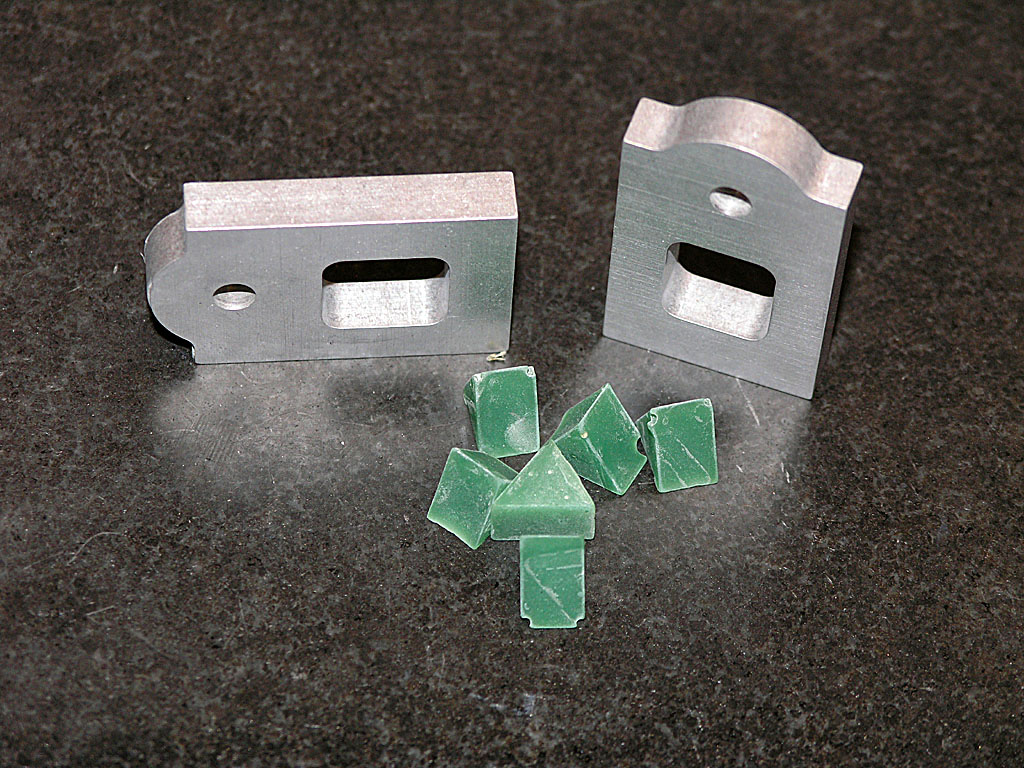

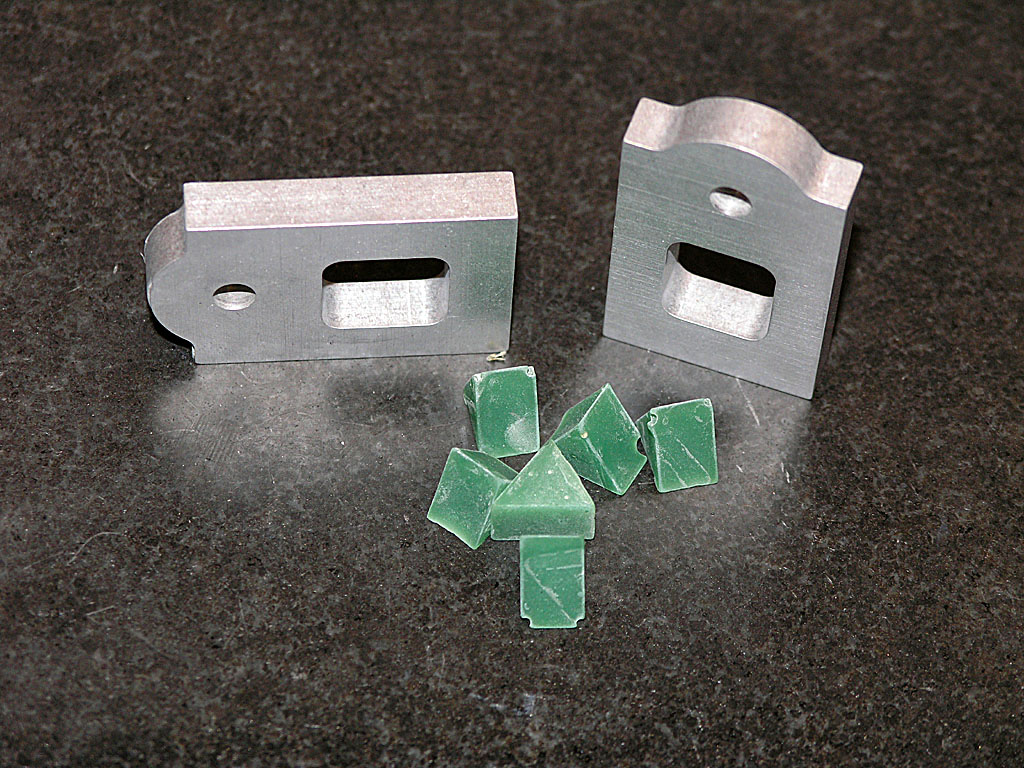

5 hours later, here is the after shot along with some of the media:

I thought it did a really nice job. The parts now have a nice overall satin finish. I could polish them up on the buffer or just leave them as is depending on the desired finish. It won't take out really deep tooling marks, but does a job on the run of the mill (pardon my pun) stuff.

I put a lot more details on how I did it up on my web page here:

http://www.cnccookbook.com/CCVibeDeburr.htm

Cheers,

BW

In any event, I had a couple hours in the shop Sunday, so I decided to try my hand at vibratory deburring. A machinist friend/mentor had been after me to give it a shot after taking a look at some of my first CNC'd parts. Since it is another process that doesn't take much supervision once underway, I decided to have a go at it.

He recommended some media to use with the 6061 aluminum I've been cutting. It consists basically of little plastic triangles. That and some water were all that is needed. You can add a little polishing soap if you have a lot of parts and it will go better.

Here is my before shot:

Quite a few tooling marks and sharp edges, especially on the part at right where I was using a dull endmill, LOL!

I grabbed a handfull of these little parts (mostly mistakes, I'm still learning the CNC), tossed them into the tumbler, and went on about my business.

5 hours later, here is the after shot along with some of the media:

I thought it did a really nice job. The parts now have a nice overall satin finish. I could polish them up on the buffer or just leave them as is depending on the desired finish. It won't take out really deep tooling marks, but does a job on the run of the mill (pardon my pun) stuff.

I put a lot more details on how I did it up on my web page here:

http://www.cnccookbook.com/CCVibeDeburr.htm

Cheers,

BW