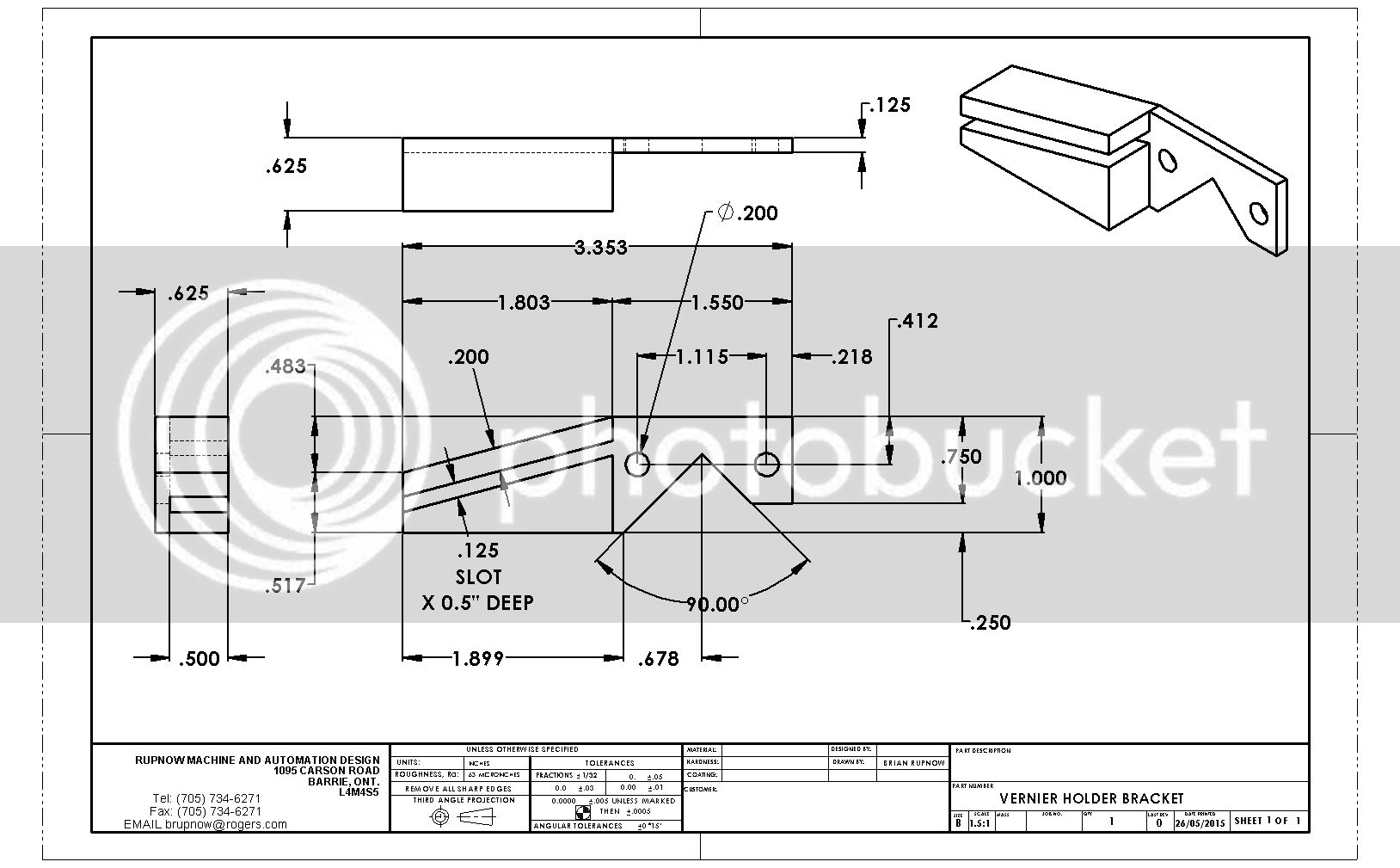

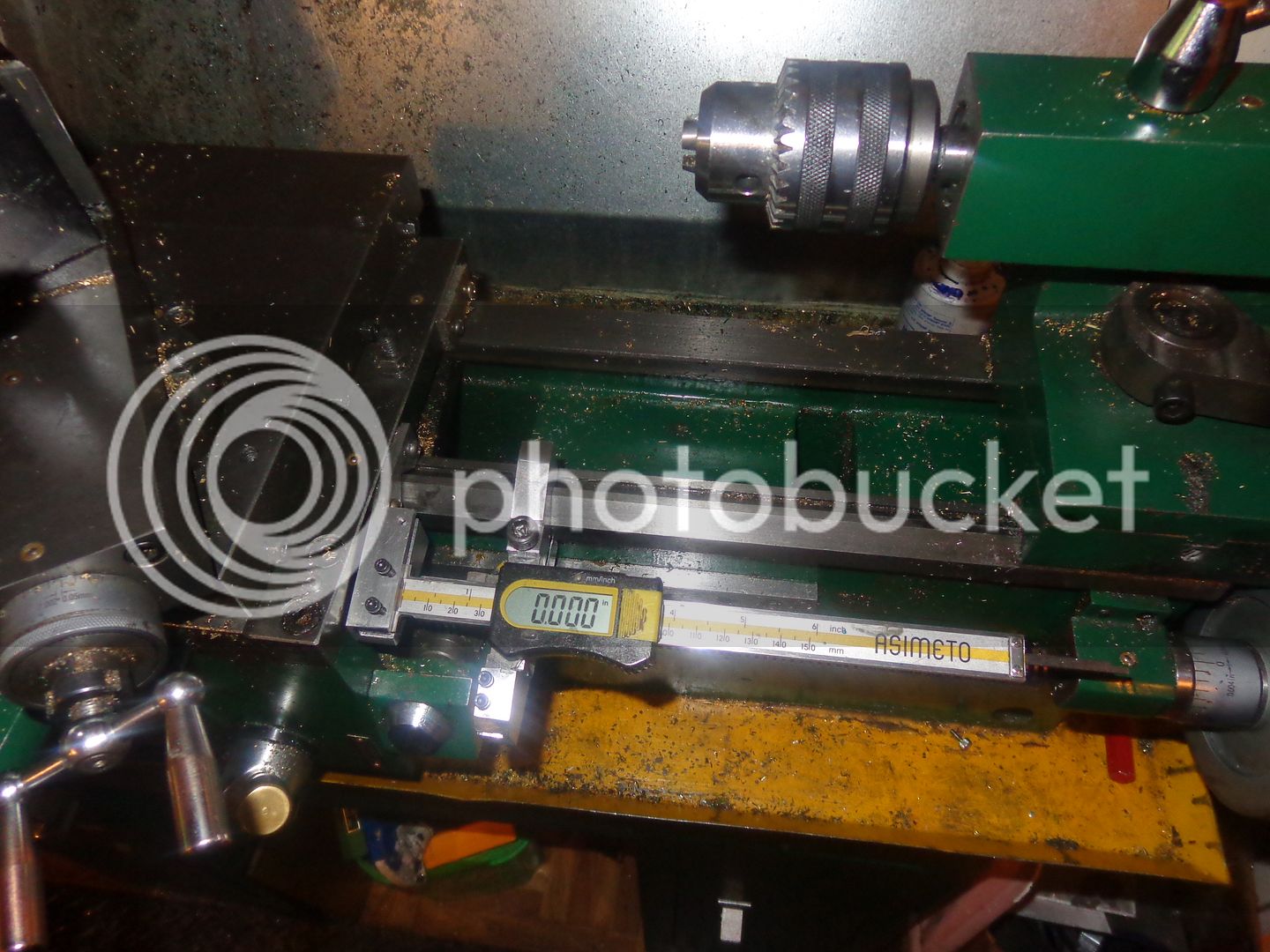

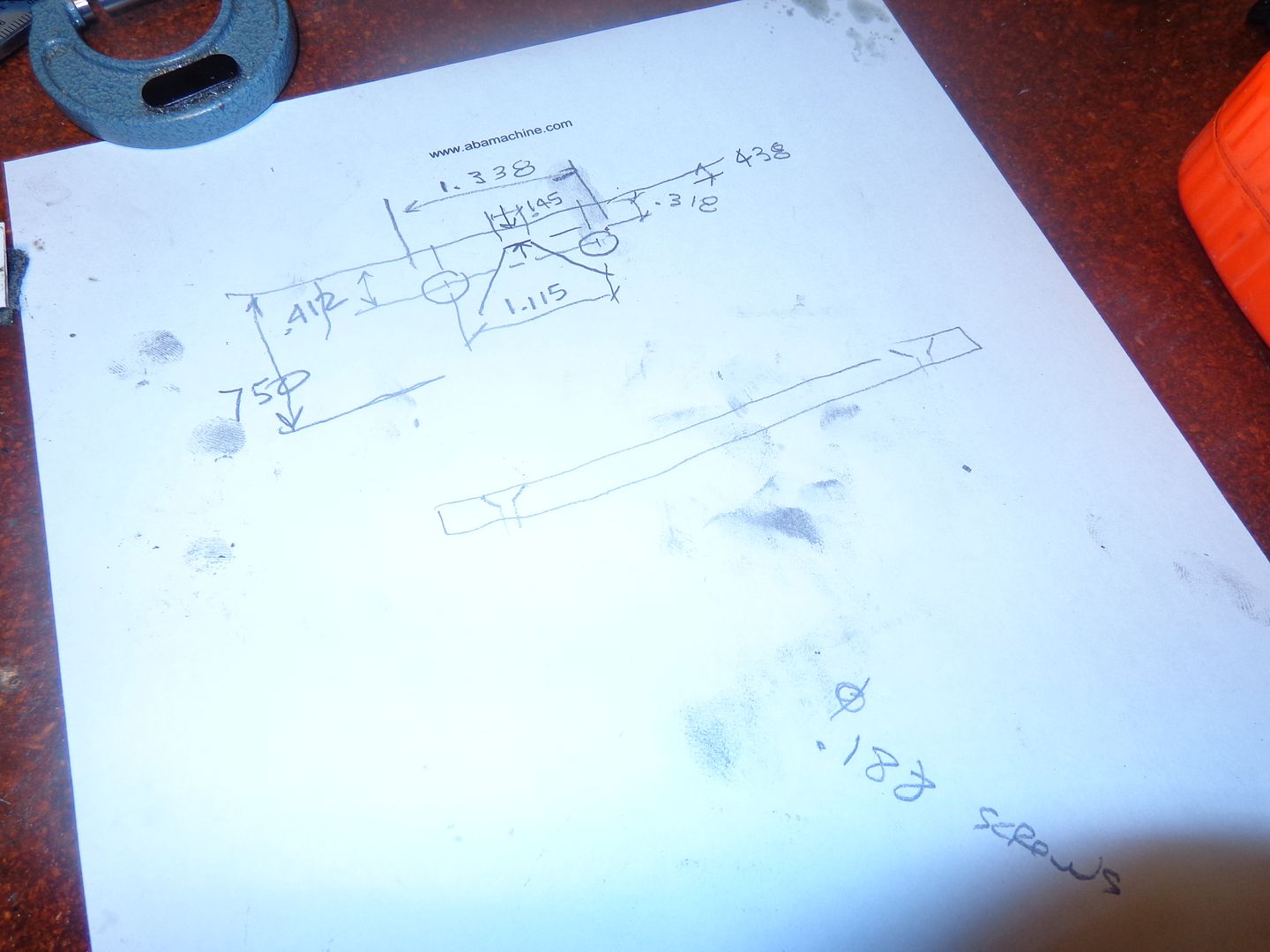

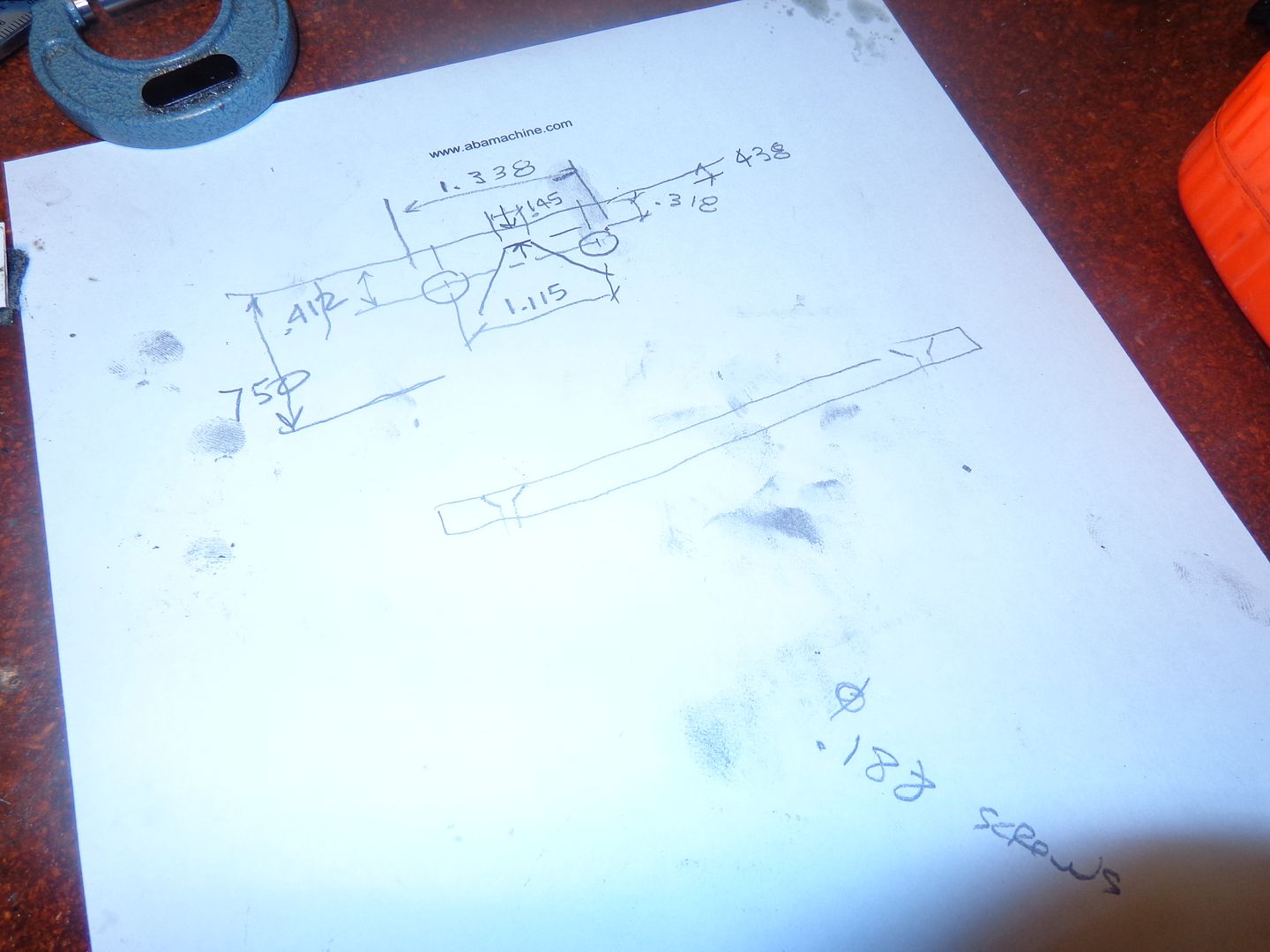

I have never been able to depend on the accuracy of the travel indicator dial on my lathe saddle. It always gets me close, but only close. If I build my "oscillating engine", I have to bore the cylinder to a very precise depth. The travel on my tailstock spindle is only 1 3/8" which is not enough. The cylinder will have to be bored with a boring tool held in the toolpost on my compound rest. For many years now I have thought about adding a Vernier caliper to my lathe to act as a poor man's DRO.----But----I didn't want to disassemble the cross slide to start drilling and tapping attachment points to it. This morning I studied on it for a while, and decided the tapped holes which hold the way-wipers would work for what I want to do, and still be able to hold the way wiper. So----First a hand sketch and some head scratching.

Last edited: