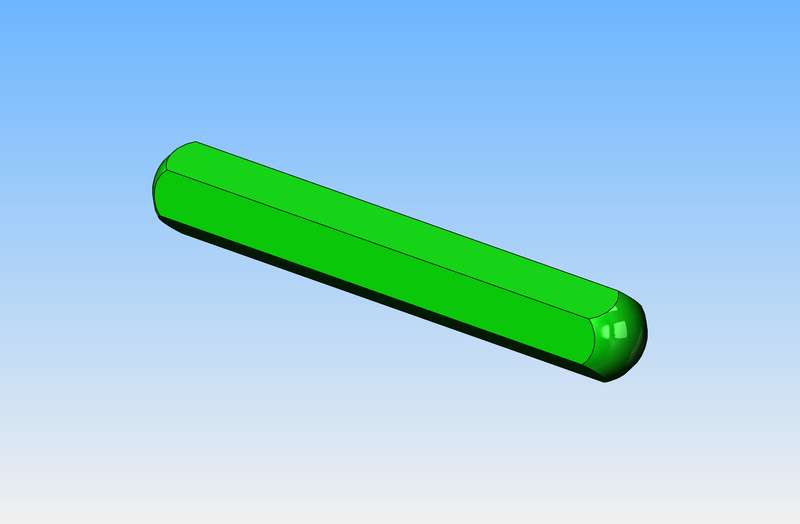

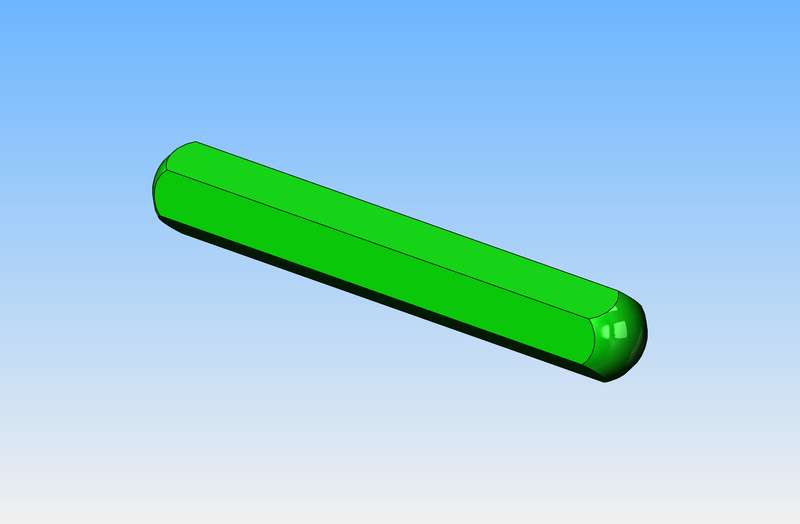

When I designed the hexagon shaped manifolds for my twin steam engine, I wanted them to have "domed" ends, so I designed them that way. Now it's true,--You can do some things on the computer that are almost impossible to do in "real life". The hex rods were drilled out full length to 1/4" inside diameter, then a brass plug silver soldered into each end. I have tried shaping a dome on the end of stock with a file, but was never terribly successful. Then I remembered the 1/2" hand held belt sander that I seldom use. It removes a lot of stock very quickly. I ran the lathe at about 200 rpm and with the running belt sander in hand I shaped the dome "freehand". It went very quickly, and gave excellent results. It worked so well that I considered it worth posting about.---Brian