You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A new attempt at making piston rings

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jan 4, 2011

- Messages

- 1,332

- Reaction score

- 343

Brian:

If you think that your cylinder is out of round perhaps you should try to lap it. A lap will make it round and if result is that the bore is oversize you can make rings to fit.

If you think that your cylinder is out of round perhaps you should try to lap it. A lap will make it round and if result is that the bore is oversize you can make rings to fit.

I remember as a teenager in the machine shop there was a Delapina Hone (American possibly?) with expanding mandrel(s) for lapping small bores. Used (by me) for sizing small ends on car con-rods after fitting new bushes (Bronze, made and fitted by me). I learned a lot working there. My father made his lap (I still use it) from a piece of broom handle (hard-wood) with a groove, springs, and 1/4" square stone slip fitted. His standard bore was 1". I remember talking to him about whether it would taper the bore, and as he was only taking the finest polish lap he explained "possibly, but not measurably, by him". It was a prototype, as he planned a mild steel version with setting screws to set the stone parallel, and for progressing the cut. But that did not become necessary.

Before I inherited that lap, I used a piece of wood dowel with layers of paper taped-on, using grinding paste on the top layer of paper, or with the top layer being 1000 grade wet and dry paper (oiled). With the paper very tight, you can increase the cut by adding a single layer of paper (+0.002" radius?) if not adequate pressure at the first attempt. It takes a lot of care and fiddle to get the cylinder fitted onto the lap, but remember, you should only be taking the peaks off the bore machining, not actually removing metal in any measurable amount. The finest grinding paste I have used (on brass cylinders) is toothpaste. ALWAYS thoroughly clean all bores after lapping. (And after they have written long texts like this one!). I think the paper lap may have "belled" the ends of the bores slightly, but I couldn't measure anything. The piston just didn't feel so tight a sliding fit at the ends... But I had the same effect when using a bought sprung lap. As a teenager, on car bores, with a tolerance of 0.001" max total variance, care was always taken to prevent any taper or belling of the ends. (DTI measured 0.0001" intervals. most bores were within 0.0004~5" variance measured in about 10 places anyway. Compared to typically 0.004" wear (or more!) on bores before we did the re-bore, it was good enough).

I am sure Brian can make a good lap anyway.

K2

Before I inherited that lap, I used a piece of wood dowel with layers of paper taped-on, using grinding paste on the top layer of paper, or with the top layer being 1000 grade wet and dry paper (oiled). With the paper very tight, you can increase the cut by adding a single layer of paper (+0.002" radius?) if not adequate pressure at the first attempt. It takes a lot of care and fiddle to get the cylinder fitted onto the lap, but remember, you should only be taking the peaks off the bore machining, not actually removing metal in any measurable amount. The finest grinding paste I have used (on brass cylinders) is toothpaste. ALWAYS thoroughly clean all bores after lapping. (And after they have written long texts like this one!). I think the paper lap may have "belled" the ends of the bores slightly, but I couldn't measure anything. The piston just didn't feel so tight a sliding fit at the ends... But I had the same effect when using a bought sprung lap. As a teenager, on car bores, with a tolerance of 0.001" max total variance, care was always taken to prevent any taper or belling of the ends. (DTI measured 0.0001" intervals. most bores were within 0.0004~5" variance measured in about 10 places anyway. Compared to typically 0.004" wear (or more!) on bores before we did the re-bore, it was good enough).

I am sure Brian can make a good lap anyway.

K2

It's time to pursue cast iron rings that seal properly again. I've just dropped about $1100 on a toolpost grinder and a heat treat oven and controller, and have them set up to work the way they are supposed to. They were bought solely for the consistency they would give to my ring making process. People on all three forums on which I post have suggested that my cylinders might not be perfectly round.--this would be one good reason that a flexible Viton o-ring will seal perfectly but cast iron rings will not.---I don't really believe that, but there is always a chance that I am wrong. All of my cylinders are made by drilling, then reaming, then honing to remove machining marks. Sometimes I lap them with brass laps, sometimes I don't. Since I still have the two rings I bought from Debolt, (Which I assume to be correct) mounted on a piston especially made for them, I guess my next trick will be to make a new cylinder and bore it to 0.005" undersize (not ream) and then lap it with one of my Acrolaps to a perfect 1" diameter, and see if the Debolt rings and dedicated piston will give a good seal in it.

Looking forward to your report, Brian.

Don

Don

Lapping out 0.005" on diameter is a lot. Such a large lapping allowance increases the risk of getting the bore 'bell-mouthed'. I would aim for boring no more than 0.002" undersize.

Okay Charles---.002 undersize.

Tomorrow I get to play detective.---if I do any work. The weather here today was just magnificent, 84 F and sunny. I spent the day mowing lawns, trimming lawns, and helping good wife put bands of adhesive around all of our deciduous trees. We are infested by Gypsy Moth caterpillars this spring, and if they can climb the trees they eat off all the leaves and can kill them. The caterpillars are very small, about 1/16" long and they spin webs. Nasty!!! I will pull the cylinder off the Vertical 2021 engine and check the cylinder bore for roundness using "snap" gauges that are spring loaded---they expand inside the bore, get locked in place, and then are taken out and measured with a micrometer. This will tell me if there is any "out of round" condition in the cylinder. I will visually check the cylinder bore to see if anything weird is going on inside the bore. Then I will visually inspect the rings to see if there are any noticeable difference in "wear patterns" on the surface of the rings. I know that the ring grooves in my piston are cut deep enough---if they weren't the piston with rings on it wouldn't fit into the cylinder. I know that the rings aren't sealing because with a couple of squirts of oil down the sparkplug hole there is lots of compression---without the oil, there is none. If I don't see anything wrong, I will make a second cylinder and see how the piston seals in it.

I question the need, in our little engines, to hone a cross-hatch pattern in the bore. Some on this forum seem to assume it is necessary, but I would ask if they have any evidence. Looking through the classic books, Westbury mentions lapping but I have not seen mention of honing. Stride says hone lightly "if desired" "just to polish off any marks" but says it should not be needed if boring was done with a sharp tool and slow feed. Mason makes a passing reference to lapping, but is otherwise mute.

If you think of brake cylinders on cars, they are ground and highly polished (smooth) and very similar size to the cylinders in question. But designed for zero leakage with slow motion, oil lubricated, and elastomeric seals at much higher pressure than our models. However my Father used on and converted it to a steam cylinder, with just a machined and polished cast iron piston. Very successful.

On infernal combustion engines, back in the 1960s, many engines ran long after the cross-hatching had worn off. But on car engines today, with steel wire rings, better manufacture, lower tangential ring pressure, better lubrication and clean air and oil, the cross-hatching can last up to 100,000 miles... There is no doubt in car engines cross hatching is necessary for lubrication, to prevent wear, but if your do tiny amounts of running - compared to the hours in a car - then probably unnecessary. But if the engine is hauling kids around the 5in park track every weekend, you will probably benefit from this extra process.

K2

On infernal combustion engines, back in the 1960s, many engines ran long after the cross-hatching had worn off. But on car engines today, with steel wire rings, better manufacture, lower tangential ring pressure, better lubrication and clean air and oil, the cross-hatching can last up to 100,000 miles... There is no doubt in car engines cross hatching is necessary for lubrication, to prevent wear, but if your do tiny amounts of running - compared to the hours in a car - then probably unnecessary. But if the engine is hauling kids around the 5in park track every weekend, you will probably benefit from this extra process.

K2

Makin chips

Member

I have to agree with Steamchick. Honing gets rid of the ridges left by boring. Look at a bored or turned surface under a microscope, looks like a fine thread. Honing or lapping will take all the sharpness off the high points or smooth them completely if enough material is removed. Depending on how course the stones or lapping compound is there will still be hills and valleys but a perfectly polished bore for an IC engine IMO leaves no room for oil to hide. I believe honing gives you a better surface for the rings to ride on (yes with a good crosshatch). Lapping can be just as effective but I would shy away from diamond compound as the cast iron we use for sleeves is soft and the diamond will impregnate in and not be able to be effectively cleaned out. I use silicon carbide compound when lapping with good results. Just my $.02 good luck on your quest Brian.

The intention of good honing, is to remove sufficient off the peaks of the machining to provide a non-wearing bearing surface, but not too much. A Doctor of tribology explained to me (if I've remembered correctly?) that too little flattening of the peaks means the oil film has excessive pressure, breaks down and Wear (running-in) occurs. The swarf dirties the oil and wears other bearing surfaces. Too much flattening of the peaks leaves larger surface area of oil, which is under low stress so maintains the oil film, but there is an excess of the film in shear, causing higher shear stress on the oil than necessary, heating it more and wasting power from the fuel. The correct honing, (about half the depth of the valleys) is a compromise that is the best between all the various factors. Hones should be fine enough that they do not cut fresh metal, but naturally stop cutting when the right amount (whatever that is!) of material has been removed from the peaks of the machining. I.E. too fine a stone will do insufficient honing, too coarse will cut the bore away from circular.

When I was a teenager, we had coarse stones to cut the glaze, on glazed bores, then fine stones (whatever grit I don't know) for finishing, or honing machined bores. The boring bar tool had a sharpish edge for boring the cast iron bores, but with maybe a 0.5 mm radius (about the same as the feed-rate of the boring bar?) to a relief behind the cutting point of just a few degrees. It was sharpened in a jig. But not by me.

I doubt that this helps much, but it is what I was taught by specialists, in both machining and tribology.

Ken

When I was a teenager, we had coarse stones to cut the glaze, on glazed bores, then fine stones (whatever grit I don't know) for finishing, or honing machined bores. The boring bar tool had a sharpish edge for boring the cast iron bores, but with maybe a 0.5 mm radius (about the same as the feed-rate of the boring bar?) to a relief behind the cutting point of just a few degrees. It was sharpened in a jig. But not by me.

I doubt that this helps much, but it is what I was taught by specialists, in both machining and tribology.

Ken

Last edited:

If the ring is not sealing the gas pressure goes between the cylinder bore and the ring face and can hold the ring away from the bore and hence prevent correct sealing. The ring needs to seal very quickly and then combustion pressure behind the ring will facilitate early full sealing. The Trimble method of making rings is fool proof if one follows the formula as presented in machining and heat treating. When the ring is compressed to the bore it conforms to a perfect circle and has worked every time for myself You just have to be patient and not rush the process but be strict tithe the formula for the ring dimension's. John

I've made replacement rings for a couple of model airplane two strokes as well as my 1" bore four stroke. Used the method in Vincent Gingery's book "building the Atkinson Cycle Engine" in addition I referred to Strictly IC magazine's article by George Trimble which helped, although I did not use the heat treating cup. Cast iron rings will take a few runs to "wear in" properly, or seat. You can see the piston and to it's right is a fixture I use to hold an individual ring for finishing in the lathe.

Well Sir, Well Sir--I just got a surprise----It might even be a good surprise. I have the two rings I purchased from Debolt installed on a new piston made especially to suit these rings in my Vertical 2021 engine. I couldn't get it to fire. I drove it with an electric motor for 1 1/2 hours hoping to seat the rings. Nothing worked. It had absolutely no compression. I've been busy buying and setting up a heat treat oven and a toolpost grinder, and just today got back to this compressionless engine. I unbolted it from the test bench in my garage, brought it into my office to do some detective work, and as soon as I removed the cylinder head it became apparent that the head gasket was broken and a piece of it was missing. HUH!!! I put my big fat thumb over the top of the cylinder and turned the engine over by hand, and their is lots of compression and suction. so---First order of things is to make a new head gasket, reassemble the engine, and try to start it again.

Glad you found the problem. I have used DeBolt rings on my "Midget" engine succesfully. An easy way to make a gasket for the head is to use some Permatex high temp RTV silicone. It's orange/red in color but it works well. You can pick it up at any local auto parts store for about $6.00 per tube, which should last for alot ofWell Sir, Well Sir--I just got a surprise----It might even be a good surprise. I have the two rings I purchased from Debolt installed on a new piston made especially to suit these rings in my Vertical 2021 engine. I couldn't get it to fire. I drove it with an electric motor for 1 1/2 hours hoping to seat the rings. Nothing worked. It had absolutely no compression. I've been busy buying and setting up a heat treat oven and a toolpost grinder, and just today got back to this compressionless engine. I unbolted it from the test bench in my garage, brought it into my office to do some detective work, and as soon as I removed the cylinder head it became apparent that the head gasket was broken and a piece of it was missing. HUH!!! I put my big fat thumb over the top of the cylinder and turned the engine over by hand, and their is lots of compression and suction. so---First order of things is to make a new head gasket, reassemble the engine, and try to start it again.

engines!

engines!High Temp. RTV Silicone Sealant, -65 to 650°F Temp. Range, Full Cure 24 hr, Red, 3 oz

- Joined

- Jan 4, 2011

- Messages

- 1,332

- Reaction score

- 343

A couple of years ago I bought a Silhouette Portrait cutter/plotter and it works great for these small engines.

Something else for Brian to buy.

Something else for Brian to buy.

Nothing is as simple as it seems. The only reason the piston was pushing or sucking on my thumb was because of the oil I had squirted down the sparkplug hole on an earlier test. So, the rings aren't sealing after all. I made a new head gasket, but that's not really where the problem lies. I have pulled the cylinder off and measured it with telescoping gauges and a micrometer, and the top bore taken two places at 90 degrees measures 1.003" and one at 1.004". The bottom measurement taken at two places at 90 degrees apart is the same. I am going to stick my neck out and say that a difference of 0.001" means that the cylinder has not "worn oval shaped". the inside of the cylinder looks fine when held up to a light. After I eat some lunch, I will pull the piston off the con rod and see what wear patterns are on the rings.

- Joined

- Jan 4, 2011

- Messages

- 1,332

- Reaction score

- 343

Take the head off and cover the top of the cylinder with your hand and see what kind of pressure/suction you have. If you have suction it means that the rings are OK so the problem is in the valves or the head. Valves can be tricky little rascals.

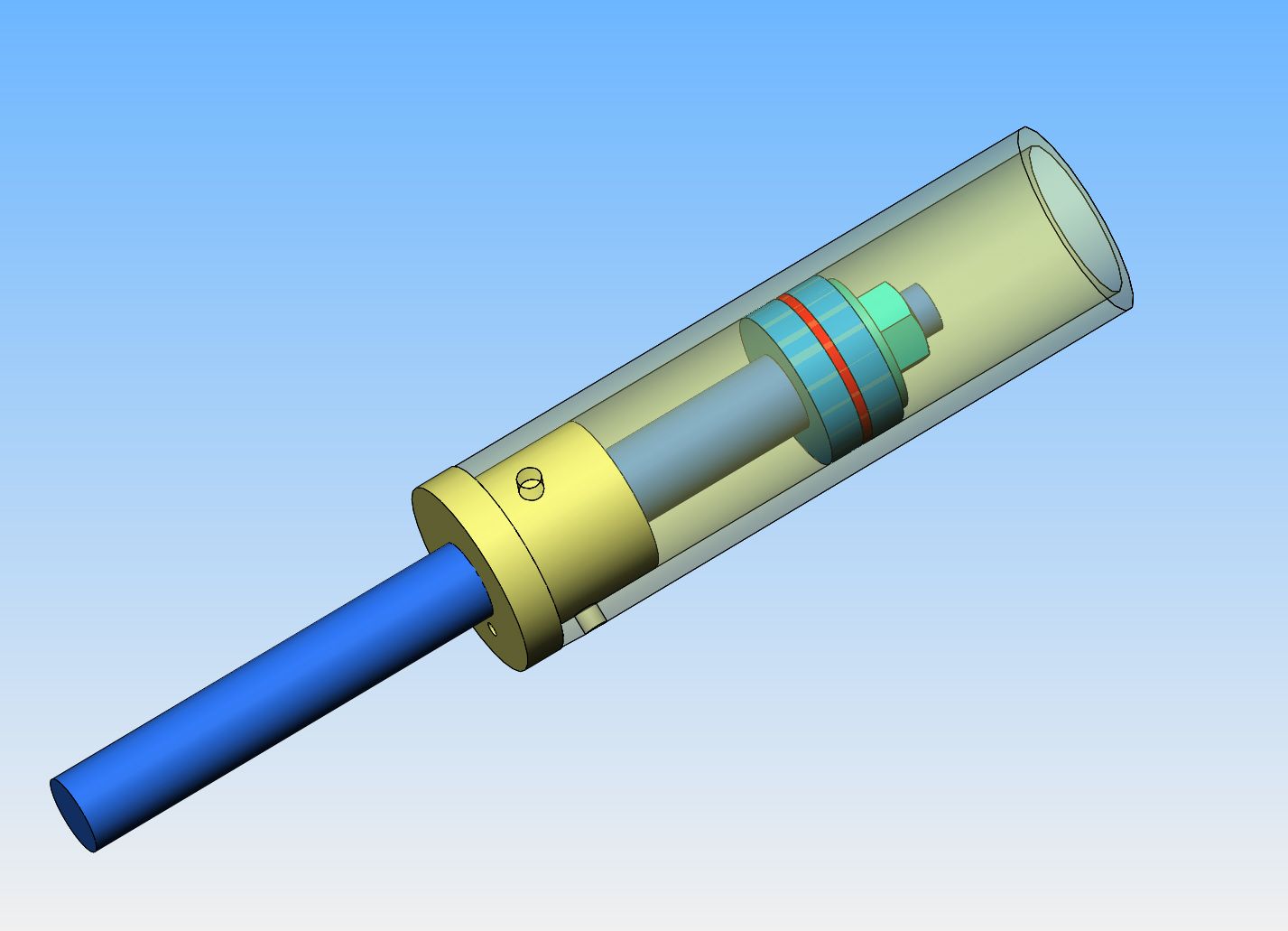

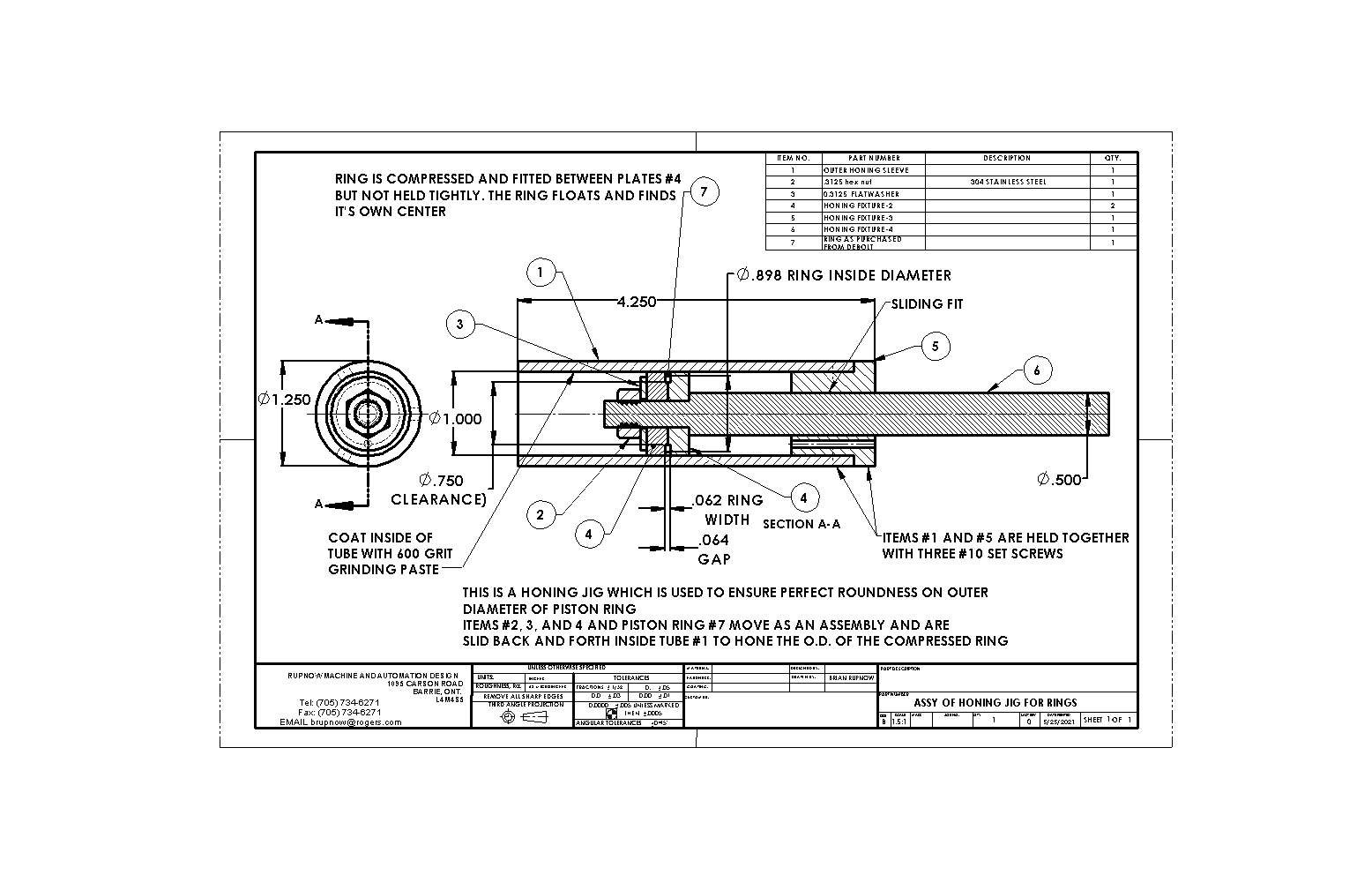

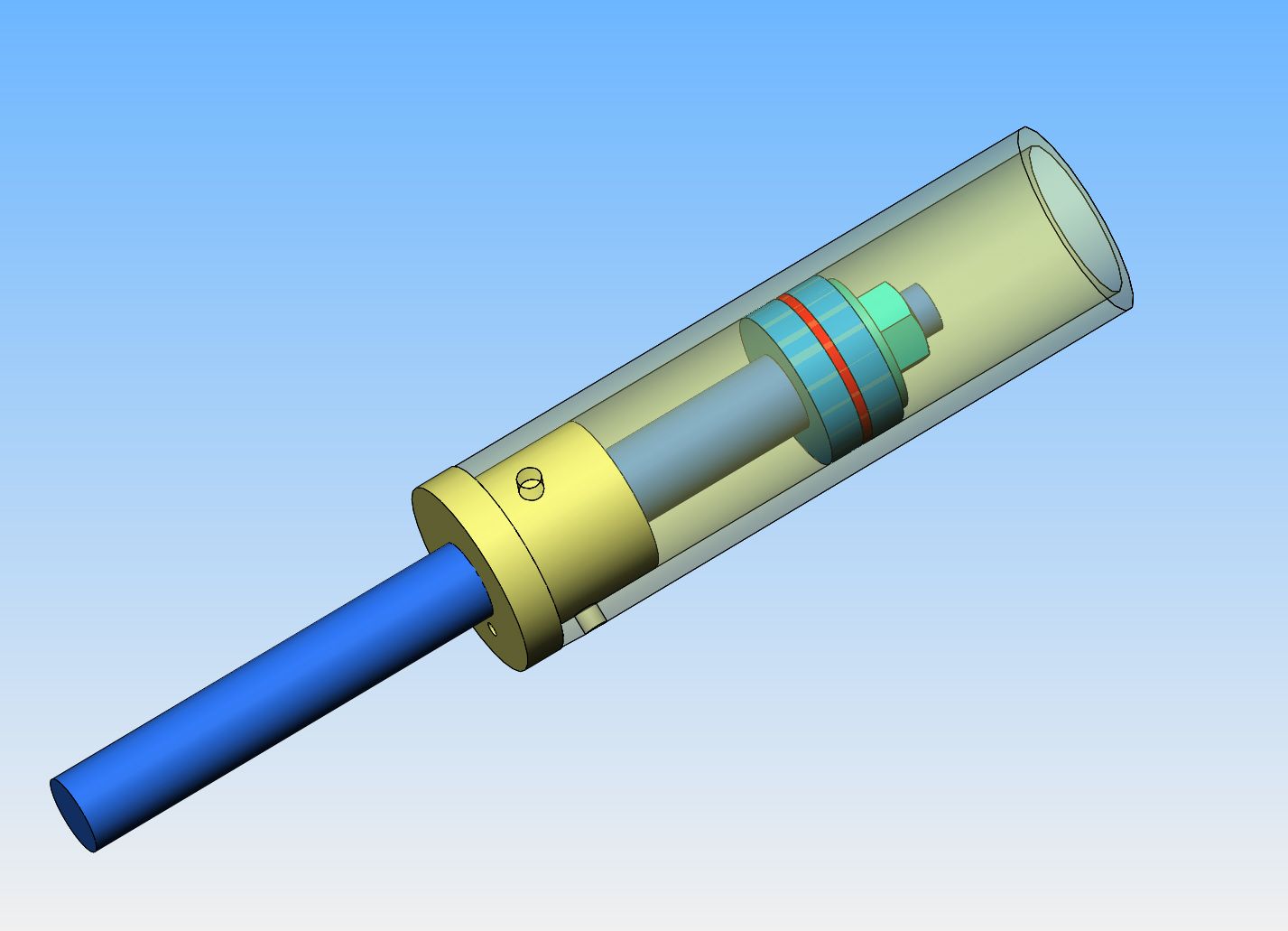

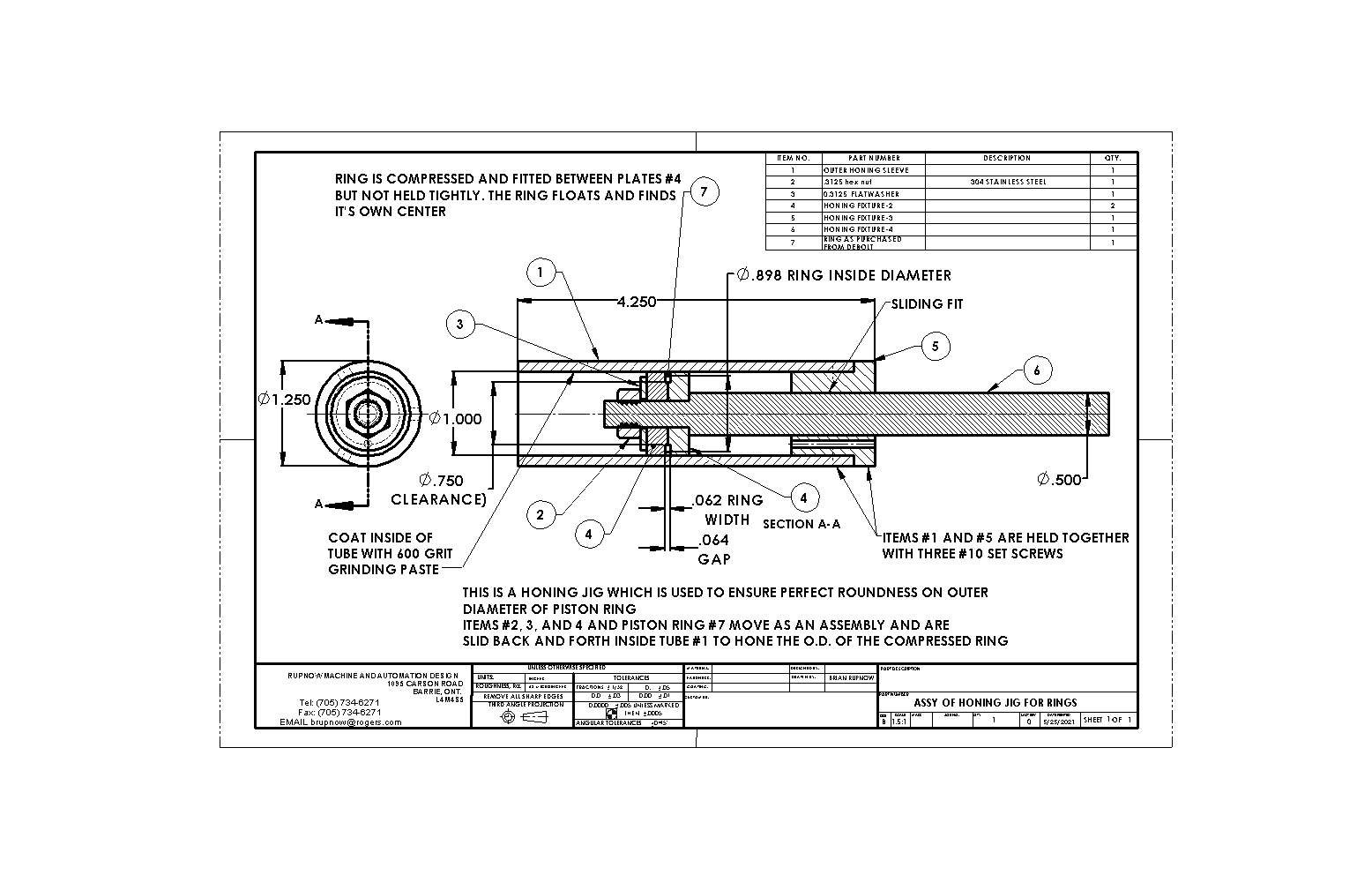

I'm not sure that it shows up in this picture or not, but there is a very uneven wear pattern on the Debolt piston rings. Some areas are shiny and you can tell they have been in contact with the cylinder wall. Other parts of the ring are still grey/black and you can tell they have not been making contact with the cylinder at all. Now I have to use my secret weapon. None of you have seen this at all, but this piece of tooling was first brought up by Ted Hansen in a 2018 copy of the home Shop Machinist. Its use is to bring the outer diameter of a ring into perfect roundness.

Similar threads

- Replies

- 5

- Views

- 2K

- Replies

- 0

- Views

- 501

- Replies

- 2

- Views

- 881