mariolucchini

Member

- Joined

- Sep 15, 2009

- Messages

- 19

- Reaction score

- 0

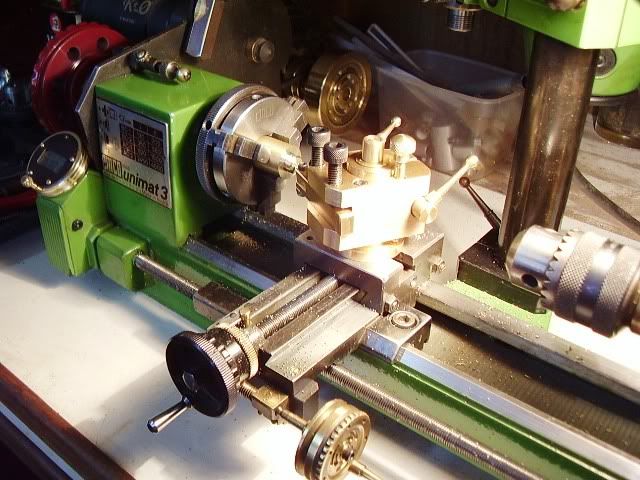

In a distraction moment from the making of the miniature lathe, I was browsing through some old Model Engineers issues when I found a toolpost design which I couldn't resist :big:.....here's the story......

Needed a chunk of brass and I found some old brass padlocks in my scrap box.....needless to say, judicious flycutting long minutes after I produced the toolpost body....

The pillar...............

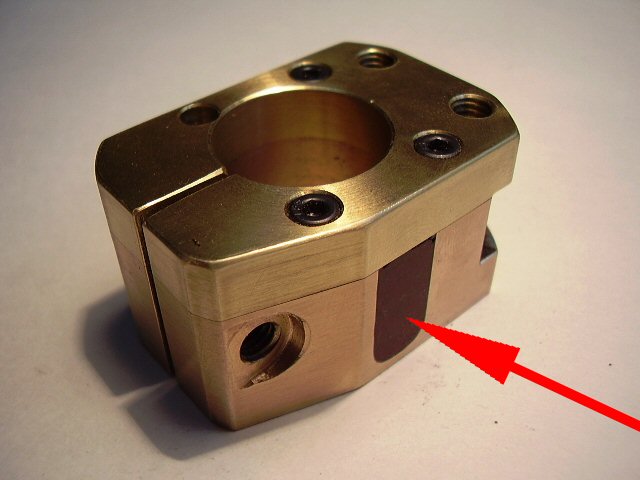

The height regulating screw......note the acrylic pad in the screw's point, this is to avoid scratching the pillar's base when you rotate the toolpost's body at a fixed height.......

The body's locking lever to the pillar....

The pillar locking lever to the lathe's cross slide....also the special washer & the "T" nut....

All the bits & pieces....

The assembled toolpost....

In a next post I'll show the toolpost doing its thing.................

Cheers...........

Mario

Needed a chunk of brass and I found some old brass padlocks in my scrap box.....needless to say, judicious flycutting long minutes after I produced the toolpost body....

The pillar...............

The height regulating screw......note the acrylic pad in the screw's point, this is to avoid scratching the pillar's base when you rotate the toolpost's body at a fixed height.......

The body's locking lever to the pillar....

The pillar locking lever to the lathe's cross slide....also the special washer & the "T" nut....

All the bits & pieces....

The assembled toolpost....

In a next post I'll show the toolpost doing its thing.................

Cheers...........

Mario