You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

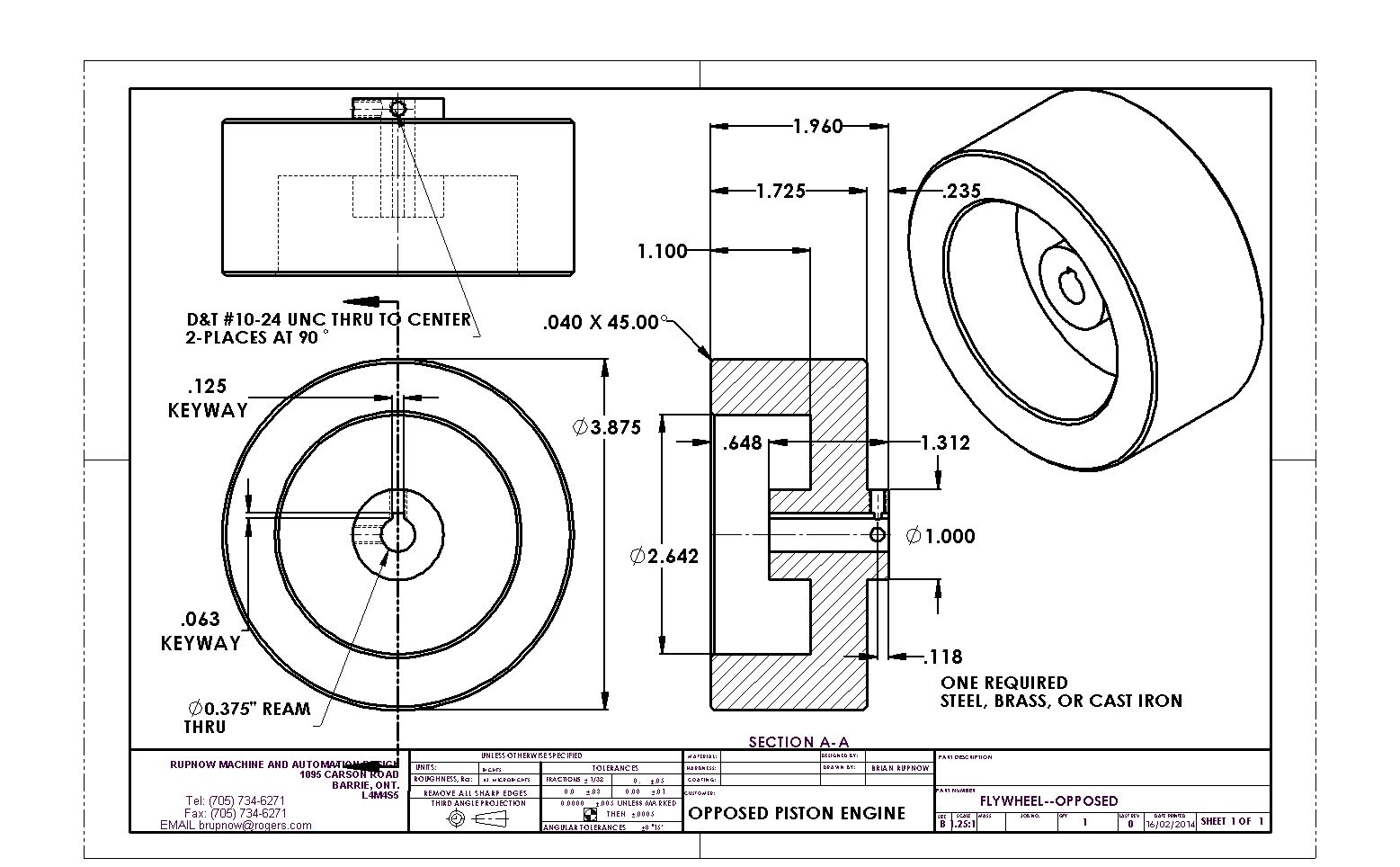

A different opposed piston engine---

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Compression ratio is 5:1---I don't think it needs it because of massive compression. It has more to do with all the pivoting joints and levers. This is not an engine that coasts very well, even with no spark plug in place.

- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

Compression ratio is 5:1---I don't think it needs it because of massive compression. It has more to do with all the pivoting joints and levers. This is not an engine that coasts very well, even with no spark plug in place.

Nice finish to the project, Brian. I'm beginning to learn that you just can't have too much flywheel. I think the lower compression ratio is also key to getting the engines to idle better.

Chuck

johnny1320

Middle aged Member

- Joined

- May 15, 2013

- Messages

- 149

- Reaction score

- 16

Wow 5:1 that is definitely not too high, seems kind of low to me

http://www.mediafire.com/download/l5kw3n56pexauty/RUPNOW_OPPOSED_PISTON_ENGINE_DRAWINGS.zipbonsoir

j'aimerais telecharger les plans ,j'ai regardé au poste 192 mais je ne vois pas de lien ?? je ne comprend pas ,comment faire

I don't speak any French.--What is this fellow asking me about in post #307? --It seems he may be having problem with the link, but the link works fine for me--I just tried it. Can someone help this fellow, please.---Brian

Pour gg89220: aller à cette adresse et télécharger. Sinon MP pour metal89 sur usinages.com

http://www.mediafire.com/download/l5kw3n56pexauty/RUPNOW_OPPOSED_PISTON_ENGINE_DRAWINGS.zip

Le plus simple est de poster en français puis d'ajouter la traduction automatique donnée par Google translation

--> To gg89220 go to the adress below and download. If any problem send me a PM on usinages.com. Next time use google translation it helps a lot

Regards

http://www.mediafire.com/download/l5kw3n56pexauty/RUPNOW_OPPOSED_PISTON_ENGINE_DRAWINGS.zip

Le plus simple est de poster en français puis d'ajouter la traduction automatique donnée par Google translation

--> To gg89220 go to the adress below and download. If any problem send me a PM on usinages.com. Next time use google translation it helps a lot

Regards

Niels Abildgaard

Well-Known Member

- Joined

- Jun 13, 2010

- Messages

- 540

- Reaction score

- 94

Opposed piston engines seem to be a dead end,but they are fun to speculate.

I have personally done it for 30 years.

http://archive.is/zHnXJ

and a later version

http://archive.is/s7gTY

If there is interest in more pictures let me know.

I have personally done it for 30 years.

http://archive.is/zHnXJ

and a later version

http://archive.is/s7gTY

If there is interest in more pictures let me know.

Every night this week I have come home from the temporary "on site" engineering contract I am working and started this engine. This is the part of building a new engine that I always have mixed feelings about. Its coming down from a big "high", pleased that the engine runs as well as it does, and relieved that I don't have to spend every spare moment of my life machining something.---But a bit lost as to what to do now that the engine is finished. I get totally burned out every time I build an engine. I don't want to build anything for a while now--just live vicariously by reading everybody else's build posts. The trouble with building successful engines, is that ordinary engines become, well, commonplace. This tends to push me towards more exotic and "different" engines. All I really want right now is for this seemingly endless winter to be over and some warm weather. I know I will build something else---but hopefully not for a while now.----Brian

One of the things I discovered, that I must tell you about. The way I made the gas tank filler cap, by using a threaded pipe nipple for the gas tank filler spout and a modified threaded pipe cap for a screw on lid works great. It gives you a much larger opening and a much better chance of filling the tank with gas without overfilling it, but there is one caveat. On my other engines, I did not put a vent hole in the fuel filler cap. I just loosened the cap half a turn to run the engines and that worked fine. On this new style of cap, the screw on cap has an internal tapered pipe thread, to match the outer pipe thread on the pipe nipple. The cap is heavy enough that with engine vibration, it will screw itself closed to the point where the engine can no longer draw fuel from the tank because of vacuum lock.--This was driving me crazy. My engine would run good for 5 minutes, then die out for no good reason.--Each time, I would check the filler cap on the gas tank and think "Huh!!! I must have forgotten to loosen that a bit after I filled it.!! Finally I figured it out---I did loosen it each time, but it would vibrate closed. I solved the issue by drilling a 0.039" hole through the center of the cap.

BaronJ

Grumpy Old Git.

One of the things I discovered, that I must tell you about. The way I made the gas tank filler cap, by using a threaded pipe nipple for the gas tank filler spout and a modified threaded pipe cap for a screw on lid works great. It gives you a much larger opening and a much better chance of filling the tank with gas without overfilling it, but there is one caveat. On my other engines, I did not put a vent hole in the fuel filler cap. I just loosened the cap half a turn to run the engines and that worked fine. On this new style of cap, the screw on cap has an internal tapered pipe thread, to match the outer pipe thread on the pipe nipple. The cap is heavy enough that with engine vibration, it will screw itself closed to the point where the engine can no longer draw fuel from the tank because of vacuum lock.--This was driving me crazy. My engine would run good for 5 minutes, then die out for no good reason.--Each time, I would check the filler cap on the gas tank and think "Huh!!! I must have forgotten to loosen that a bit after I filled it.!! Finally I figured it out---I did loosen it each time, but it would vibrate closed. I solved the issue by drilling a 0.039" hole through the center of the cap.

Brian, if you recall I did ask if you had missed putting a vent hole in the cap. :hDe:

BaronJ--Mea Culpa----Brian

I have discovered something about the engine that gives me pause for thought. On all of my other engines with Viton O-rings, when I turn them up to compression stroke by hand, there is absolute silence at the open end of the cylinder, and the compression does not fade away. On this engine, I can hear air hissing as it escapes past the rings, and the compression does gradually die away to nothing. It is definitely escaping past the rings, not the valves. Now why would that be?--I have a couple of thoughts, but they are only vague, semi formed thoughts at the moment. Firstly--Was the inner bore of the cylinder a bit rough, to the point where it "sanded away" some of the outer diameter of the current O-rings? If so, the bore should be smooth enough by now after all this running to allow a new set of O-rings to be installed and not cause any wear on their outer diameters, thus giving a much better seal.----Did I turn the grooves in the pistons a bit too deep?---I don't think so. if they aren't turned to the depth given, it makes the engine so stiff that it won't "turn over". Do I perhaps need two rings on each piston? --Well, yes, that is possible, but it seems unlikely, as my other engines have only one ring, and they seal 100%. The engine runs good now, and I may not spend any more time on it, but still, that escaping air bothers me. I guess the cheapest potential fix is to try a new set of rings on it and see what that does. I see the plans I posted for this engine have been downloaded 157 times, so I really hope someone else steps forward and builds this engine and posts about their progress.----Brian

BaronJ

Grumpy Old Git.

Hi Brian,

Has it occurred to you that the pistons may not actually be running exactly parallel to the bore. If you draw an arc from the centre of the pivot pin you will see that it follows a curve. This will cause the piston to want to rock up and down across its length. I suspect that this is where you are getting leakage.

Has it occurred to you that the pistons may not actually be running exactly parallel to the bore. If you draw an arc from the centre of the pivot pin you will see that it follows a curve. This will cause the piston to want to rock up and down across its length. I suspect that this is where you are getting leakage.

Similar threads

- Replies

- 25

- Views

- 3K