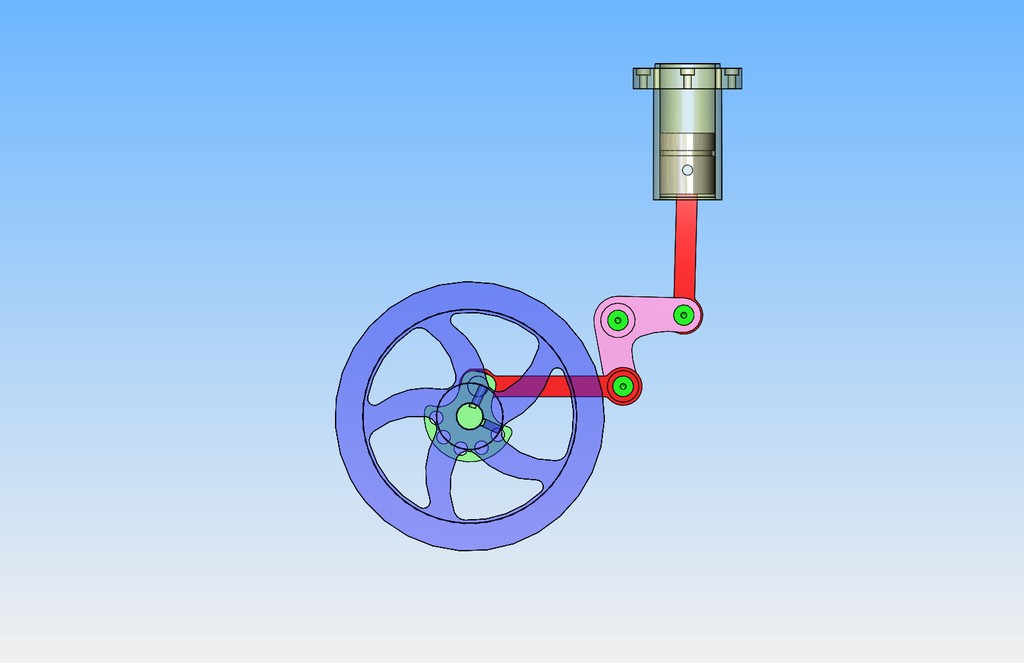

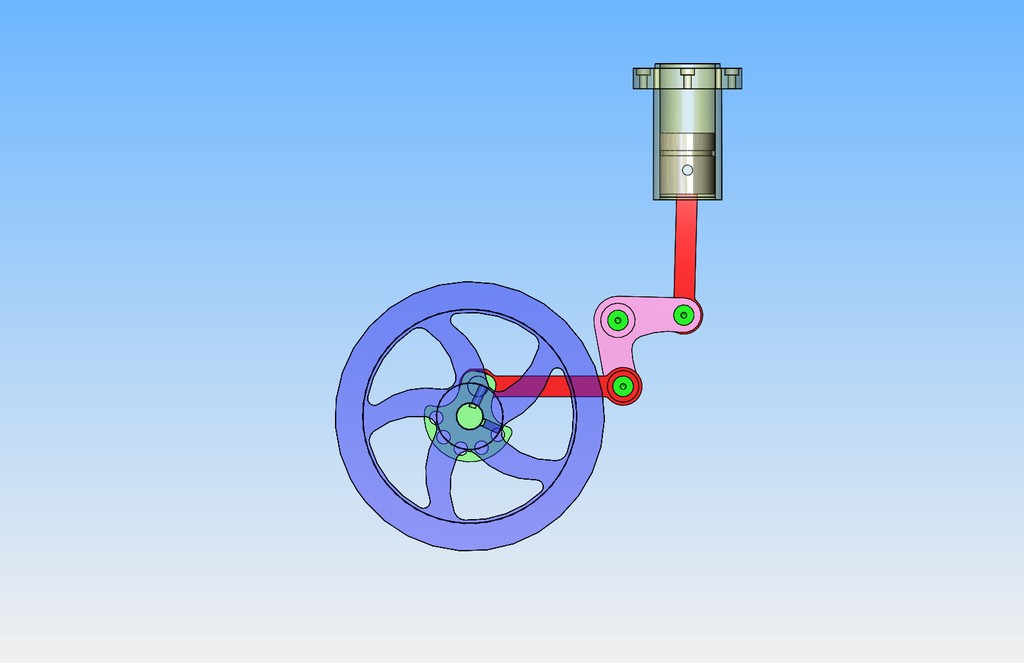

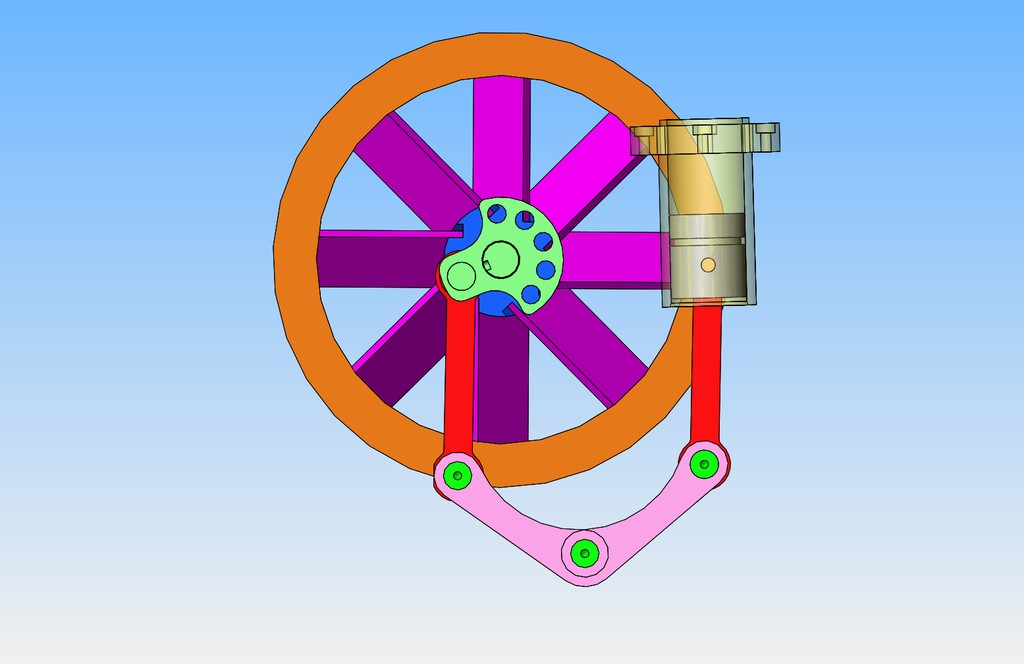

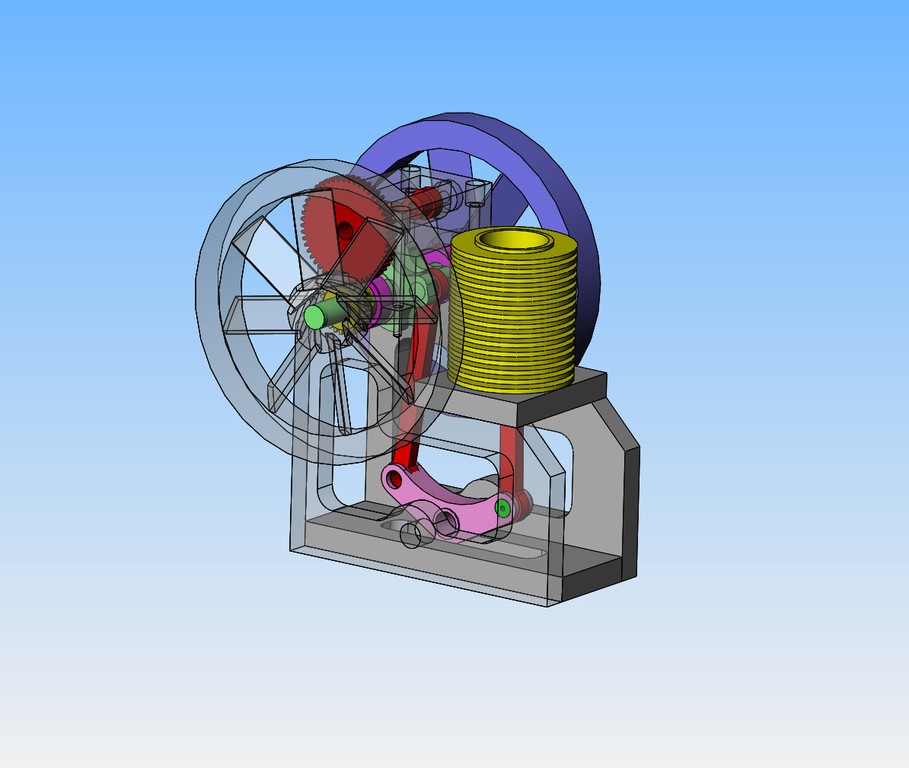

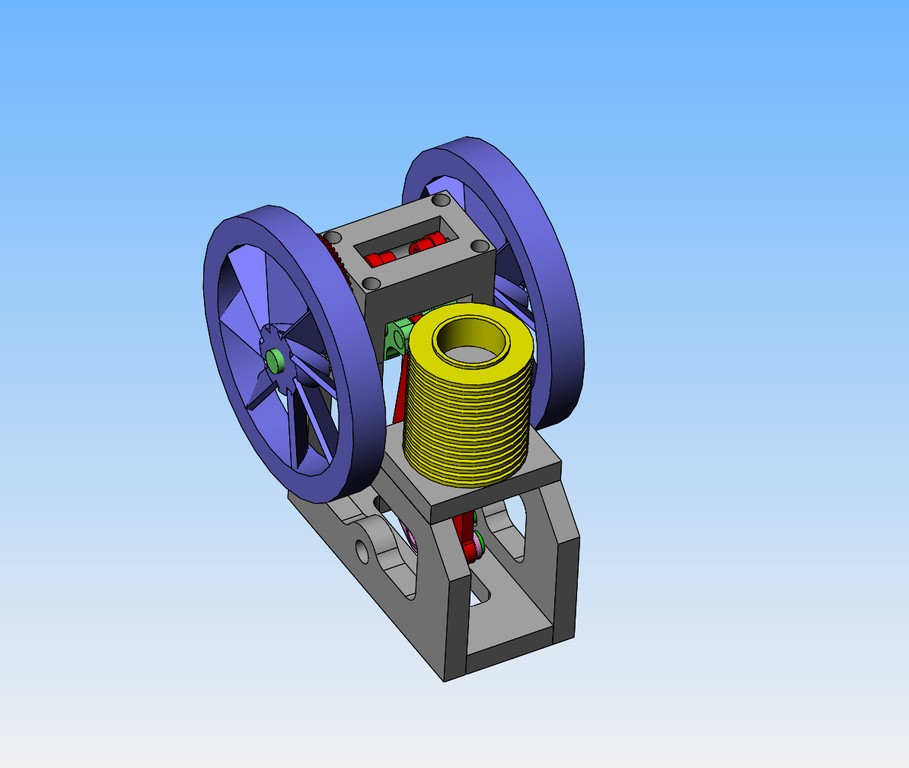

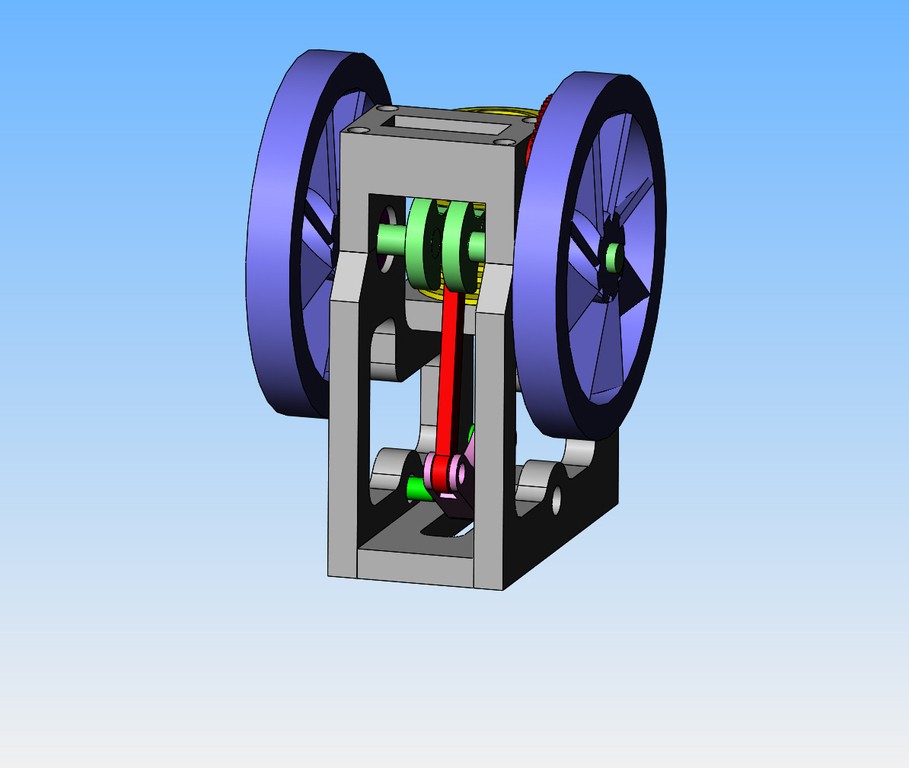

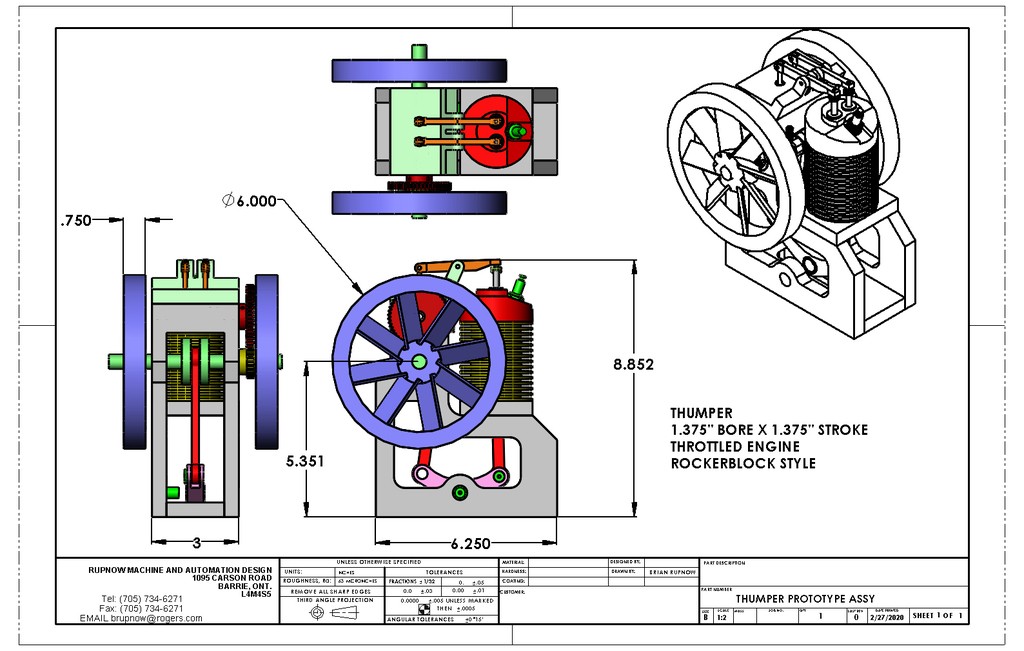

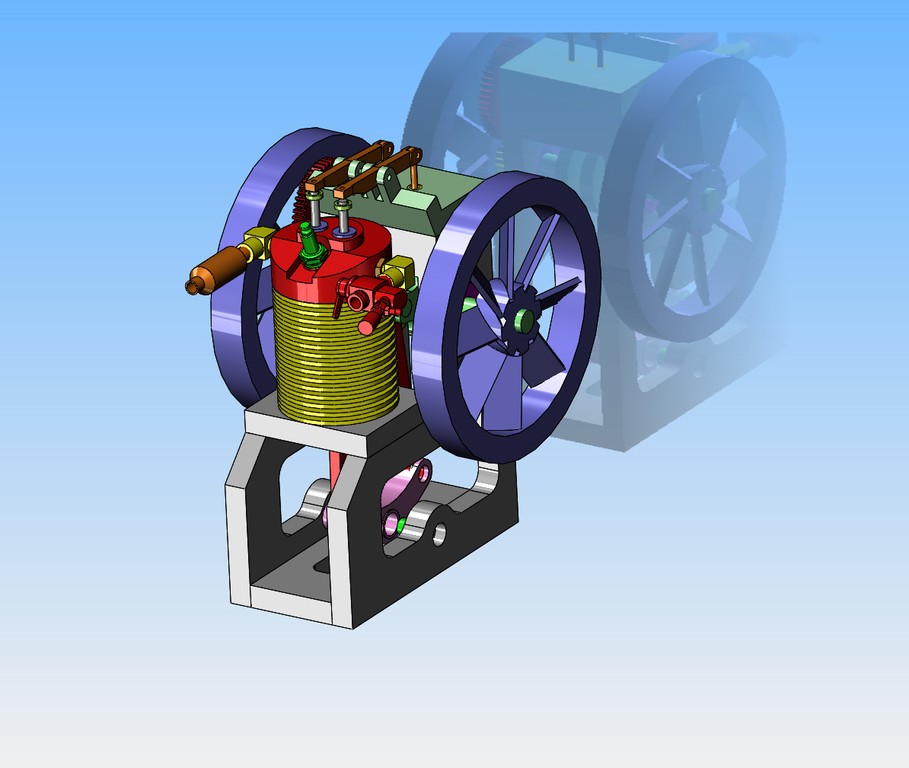

Has anyone seen an i.c. engine which operates with the crankshaft being driven by a "Bell Crank"? The closest I have seen to this is the Rockerblock engine which I designed and built a few years ago. I'm casting about looking for a new engine to design and build, and I don't remember seeing this configuration before.---Brian