You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

9x19 CNC Conversion

- Thread starter 1hand

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

thanks for the welcome back. Its been a real busy construction season here this year. Haven't had anytime since spring to do much in the shop. I can finally see the light at the end of the tunnel, only a couple more months and should have some more free time. Figure I'd start rounding up a few odds and ends now for the winter projects.

Glad to be back even if its part time.

Matt

Glad to be back even if its part time.

Matt

got a few things from Mcmaster carr today for the conversion.

also pick up some dual pole toggle switches so i can use the same driver from the mill and flip 3 toggles instead of changing cables each time.

the two steppers that I'll be using

Matt

also pick up some dual pole toggle switches so i can use the same driver from the mill and flip 3 toggles instead of changing cables each time.

the two steppers that I'll be using

Matt

showing their 20 amps @ 30 vdc..........

http://www.mcmaster.com/#catalog/116/858/=9afyi7

the info i have on the keling steppers show 3.5 amps.

I hope they will work????

Matt

http://www.mcmaster.com/#catalog/116/858/=9afyi7

the info i have on the keling steppers show 3.5 amps.

I hope they will work????

Matt

RonGinger

Well-Known Member

It is strongly advised to never put a switch between a stepper and the driver. If it ever gets flipped while the motor is powered on it is almost sure to blow the drivers.

I thought i would fab a guard or shield the toggles from accidental switching. Seems doing it this way would be lots easier than switching cables each time. As long as the drivers power is off when the switch is made, should work fine I think.

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

another option lock them behind a panel or a rod through the guards. you want easy to switch when needed but not easily mistaken or accidentally tripped. good stuff man.

Tin

Tin

rcfreak177

Well-Known Member

- Joined

- Mar 18, 2010

- Messages

- 324

- Reaction score

- 68

G'day Matt, I too have converted the same type of lathe to cnc. Just wondering what size steppers are you using? Are you going to run the spindle with complete control via Mach3?

here is a picture of my machine, mind you I have finished the machine guards etc now, the pic is a few months old. Also a QCTP has been added with the 4 bolt mounting upgrade (Highly Recommended If Not Already Done).

I run full spindle control using a 2hp 3 phase motor, 3 hp single to 3 phase VFD and a CNC4PC C6 speed control board. I use the machine to manufacture specialized bolts so accurate threading is paramount, it works very well. Hope your conversion goes well, I am following.

Cheers Barry.

here is a picture of my machine, mind you I have finished the machine guards etc now, the pic is a few months old. Also a QCTP has been added with the 4 bolt mounting upgrade (Highly Recommended If Not Already Done).

I run full spindle control using a 2hp 3 phase motor, 3 hp single to 3 phase VFD and a CNC4PC C6 speed control board. I use the machine to manufacture specialized bolts so accurate threading is paramount, it works very well. Hope your conversion goes well, I am following.

Cheers Barry.

Hey Barry;

I'm using 381 oz-in steppers the same ones I have on my SX3 mill. I see that you got you cross slide ballscrew inside the crossslide, I just mounting my to the outside for now to get it up and running. Also just going to drive it off the tailstock end for now too. I kinda screwed up turning down the ballscrews didn't get a decent cut or finish on them, so may end up replacing them later and using the bearings I got instead of stock mount. Been keeping my eyes open for a DC spindle motor but looks costly. May just end up getting a Mini lathe later to do threading opps.

Its not going to be the way I want it to begin with. I just need to get it up and running for a few turning projects, then I'll tinker with the more complex mounts and bearings. I try annealing the ballscrews, but that is some really tough crap to cut.

Got rained out at work today, so I'm going to try and get the stepper mounts milled out.

Thanks for the pic of yours will sure help in the future when cherrying my out.

Matt

I'm using 381 oz-in steppers the same ones I have on my SX3 mill. I see that you got you cross slide ballscrew inside the crossslide, I just mounting my to the outside for now to get it up and running. Also just going to drive it off the tailstock end for now too. I kinda screwed up turning down the ballscrews didn't get a decent cut or finish on them, so may end up replacing them later and using the bearings I got instead of stock mount. Been keeping my eyes open for a DC spindle motor but looks costly. May just end up getting a Mini lathe later to do threading opps.

Its not going to be the way I want it to begin with. I just need to get it up and running for a few turning projects, then I'll tinker with the more complex mounts and bearings. I try annealing the ballscrews, but that is some really tough crap to cut.

Got rained out at work today, so I'm going to try and get the stepper mounts milled out.

Thanks for the pic of yours will sure help in the future when cherrying my out.

Matt

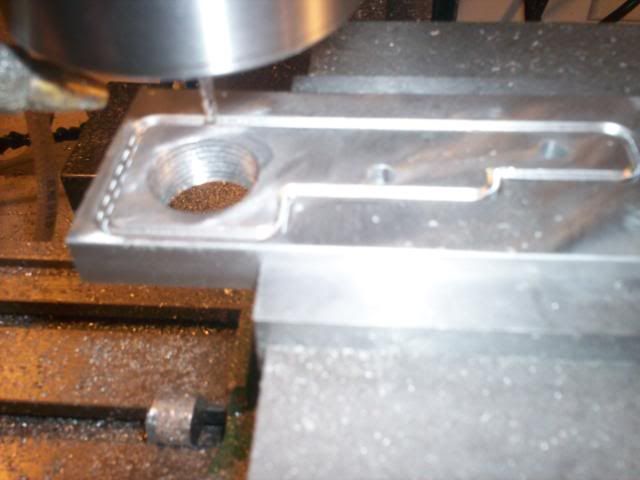

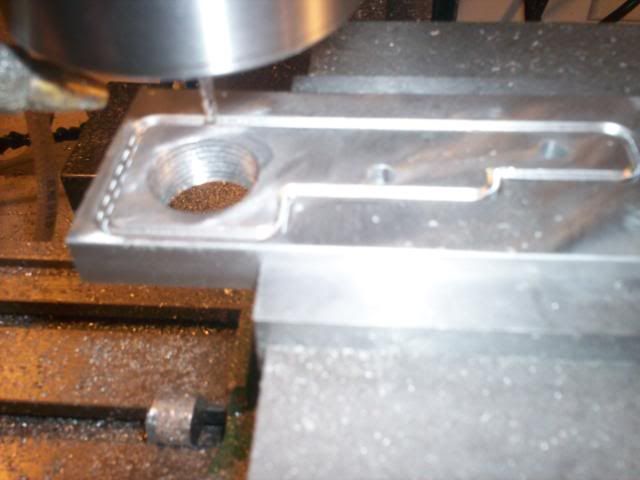

Went to work on the cross slide ballscrew mount today

Vised a piece of .50" and milled the mounting holes. Then the hole for the ballscrew.

Tapped 15/16-16 for the ball nut.

Then continued to mill out the profile.

Here we have it all mounted up to the cross silde.

;DMatt

Vised a piece of .50" and milled the mounting holes. Then the hole for the ballscrew.

Tapped 15/16-16 for the ball nut.

Then continued to mill out the profile.

Here we have it all mounted up to the cross silde.

;DMatt

Received a 5"x7" project box today from Radio Shack to house the 3 toggle switches.

Goal for the weekend is to make 1 more stepper mount, a ballnut mount for the Z axis, and wire the steppers and switches. If all goes well, should be operating by Sunday I hope.

Matt

Goal for the weekend is to make 1 more stepper mount, a ballnut mount for the Z axis, and wire the steppers and switches. If all goes well, should be operating by Sunday I hope.

Matt

What a score today! Brought two old chairs to the junkyard to get rid of, and what ya know, someone just dropped off a treadmill. So unloaded the chairs and loaded the treadmill up. Now I have my donor DC variable speed motor, but only after the wife gets sick of walking on it of course. Merry Christmas honey!! The activation key was missing, but nothing a little jumper wire and solder won't fix. :big:

Matt

Matt

Similar threads

- Replies

- 17

- Views

- 2K

- Replies

- 13

- Views

- 2K