You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

90 degree V-twin engine

- Thread starter gbritnell

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

Hi George. Your project looks fantastic, and is moving along much faster than I imagined. You have managed a huge amount of work in a very short period of time. The patience you exhibit to execute the fine detailed work on your build is beyond my my comprehension. Your work is true craftsmanship of the highest degree.

Have you ever tried putting a coat of Automotive Poly Sealant on bare metal for long term protection. It seems to be working well to prevent oxidation caused by exposure and handling. The product I use is not really a wax or polish. Its some sort of Polymer that bonds with the surface of the raw metal. Sometimes its referred to as "a once a year car polish".

-MB

Have you ever tried putting a coat of Automotive Poly Sealant on bare metal for long term protection. It seems to be working well to prevent oxidation caused by exposure and handling. The product I use is not really a wax or polish. Its some sort of Polymer that bonds with the surface of the raw metal. Sometimes its referred to as "a once a year car polish".

-MB

gbritnell, I want to thank you for making me aware of this website (from Smokstak), (my first post here) it seems like there are a lot of great people on here that share the same intrests as myself. I have taken the time to post my projects on other websites with very little interest or response, it kinda makes one feel as though it is time wasted, anyway, I think you have raised the bar out of reach on this one, I mean that in a good way, fantastic job, I think we all can agree this one is going to set the standards for some time to come. I look forward to more.

Metal Butcher, I like to leave my things without paint for two reasons, the colored paint can cover up detail and secondly when painted, some things are hard to tell from Chinese die cast. I have not had good luck with clear paint (lacquer or polyurethane) over bare polished metal, somehow it seems to rust or tarnish under the paint, or maybe I did something wrong, if there is a way to protect the shiny stuff with clear that someone knows of, I am certainly listening.

Thanks Tad

Metal Butcher, I like to leave my things without paint for two reasons, the colored paint can cover up detail and secondly when painted, some things are hard to tell from Chinese die cast. I have not had good luck with clear paint (lacquer or polyurethane) over bare polished metal, somehow it seems to rust or tarnish under the paint, or maybe I did something wrong, if there is a way to protect the shiny stuff with clear that someone knows of, I am certainly listening.

Thanks Tad

- Joined

- Jul 16, 2007

- Messages

- 2,975

- Reaction score

- 1,043

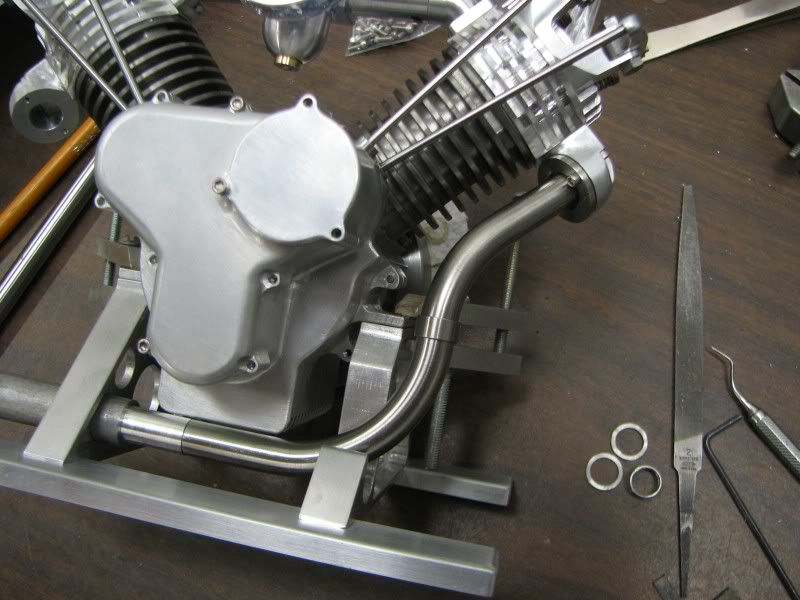

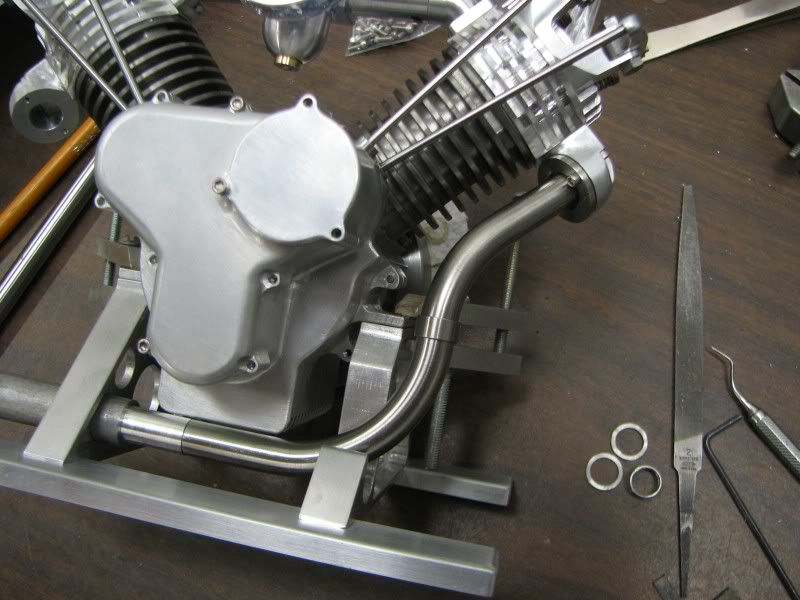

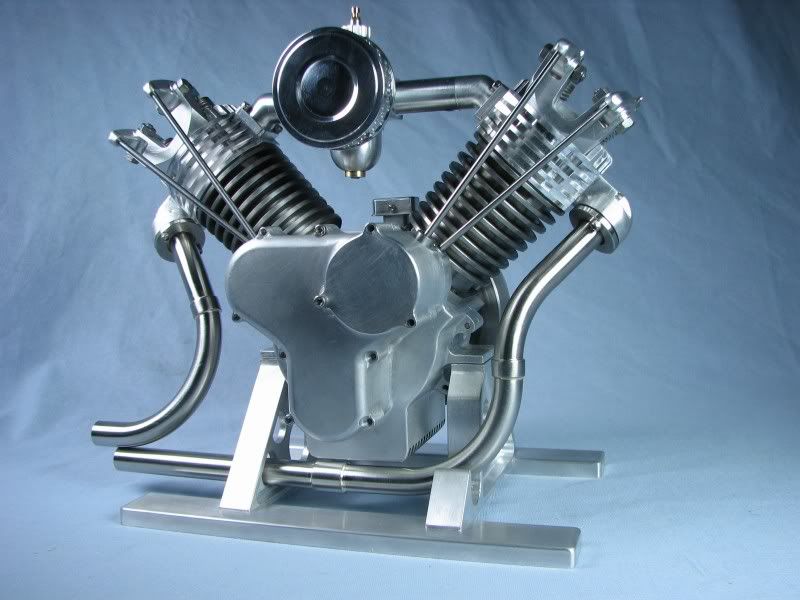

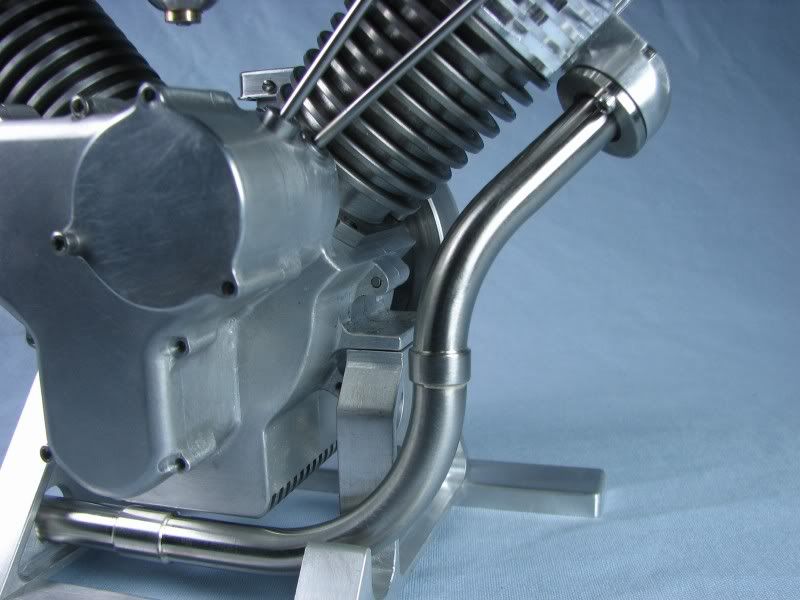

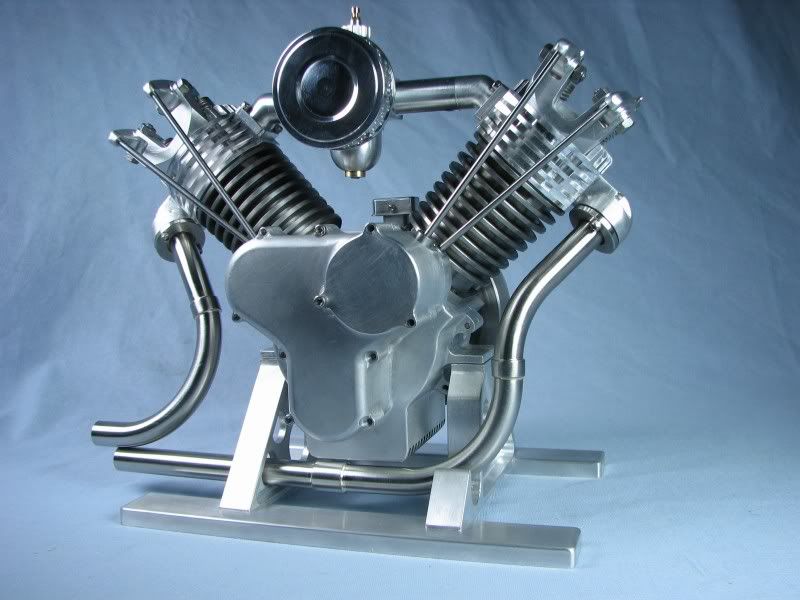

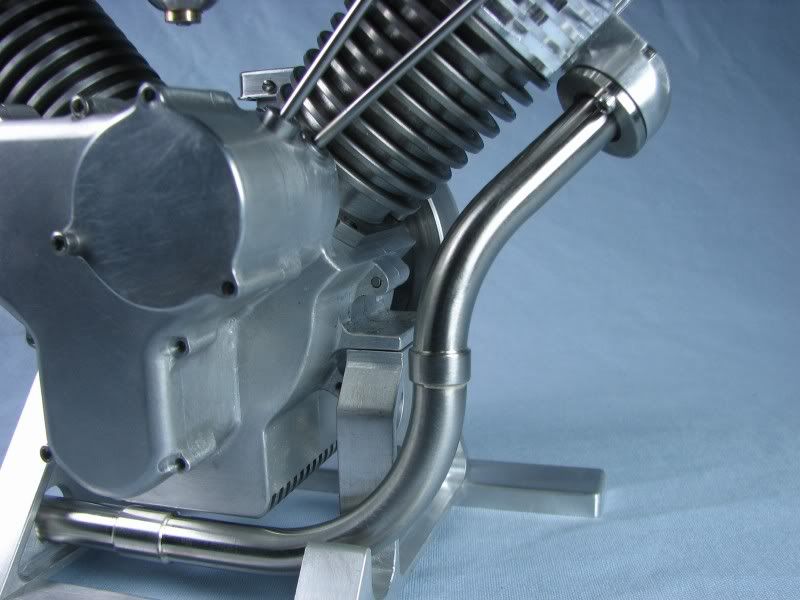

Gentlemen, it's been awhile since I updated my build. I had to make a tubing bender for the exhaust which I posted under the tools section. With the front exhaust having to fit through the engine stand I didn't know how many times I would have to put compound bends into a piece of pipe to get what I needed so I opted for a small joint in the pipe. Along with this was the necessity to pour Cerro alloy into the tubing for bending. I didn't want an extremely long piece of tubing.

The first set of pictures show the assembly and fitting of the front header pipe. I bent up two pieces of tubing, one with a 30 degree bend for the upper pipe and one with a 90 degree bend for the lower pipe. I took it slowly, removing only .06 at a time till everything lined up. I turned up the coupling from a piece of 303 stainless. I drilled it under size and then bored it out to the pipe diameter leaving a stop in the middle so that it would be evenly spaced on the pipes. I then turned a piece of aluminum to locate the rear of the pipe relative to the hole in the rear frame.

With everything fitted I fluxed it up and silver soldered it together. A quick dunk in boiling water to remove the flux and then some polishing with emery paper.

The first set of pictures show the assembly and fitting of the front header pipe. I bent up two pieces of tubing, one with a 30 degree bend for the upper pipe and one with a 90 degree bend for the lower pipe. I took it slowly, removing only .06 at a time till everything lined up. I turned up the coupling from a piece of 303 stainless. I drilled it under size and then bored it out to the pipe diameter leaving a stop in the middle so that it would be evenly spaced on the pipes. I then turned a piece of aluminum to locate the rear of the pipe relative to the hole in the rear frame.

With everything fitted I fluxed it up and silver soldered it together. A quick dunk in boiling water to remove the flux and then some polishing with emery paper.

- Joined

- Jul 16, 2007

- Messages

- 2,975

- Reaction score

- 1,043

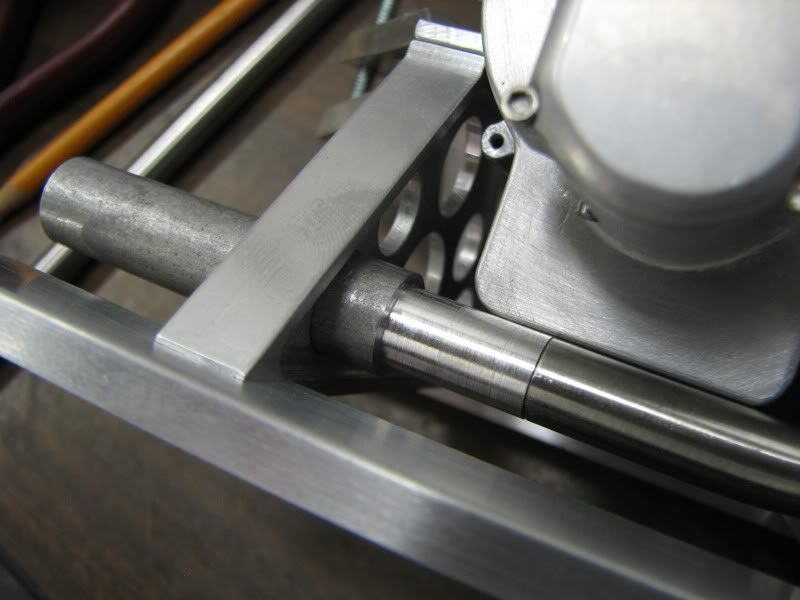

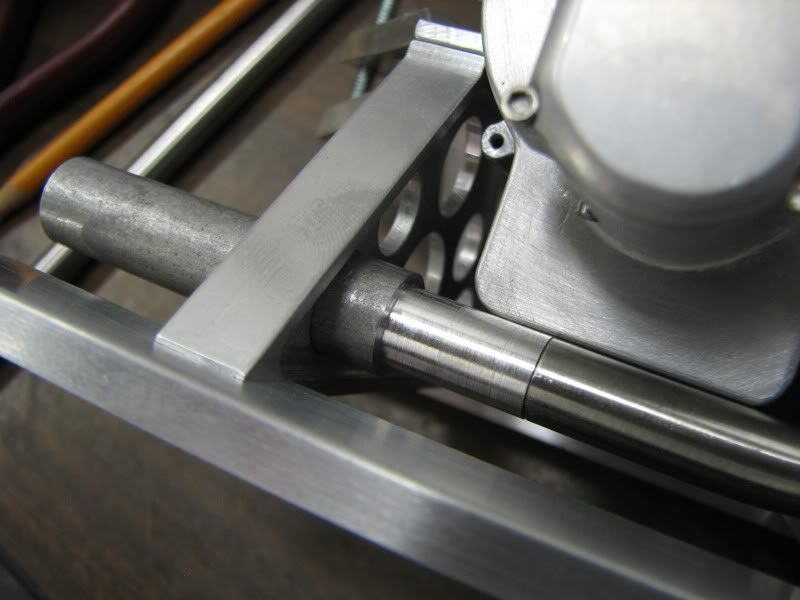

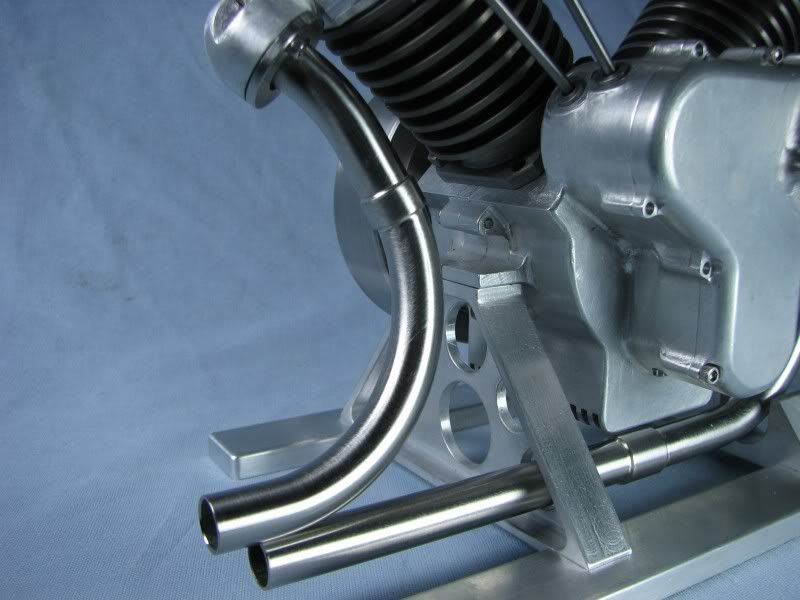

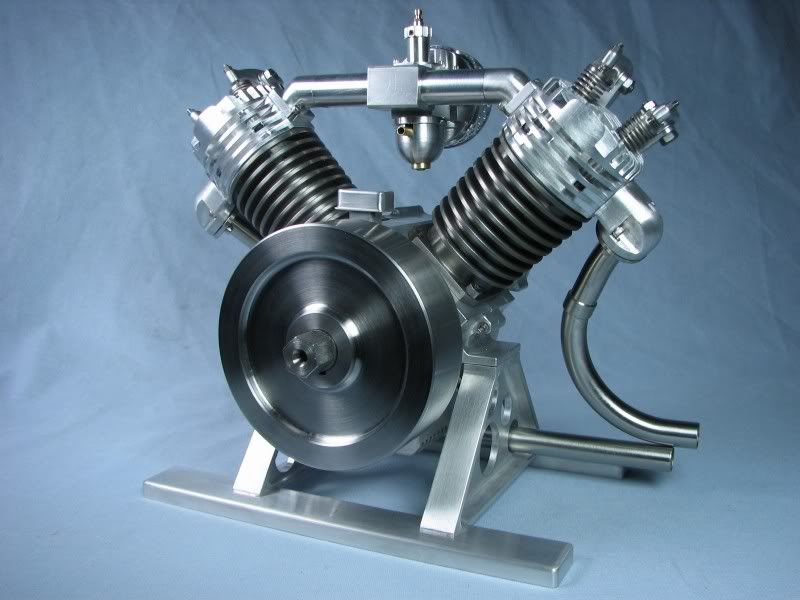

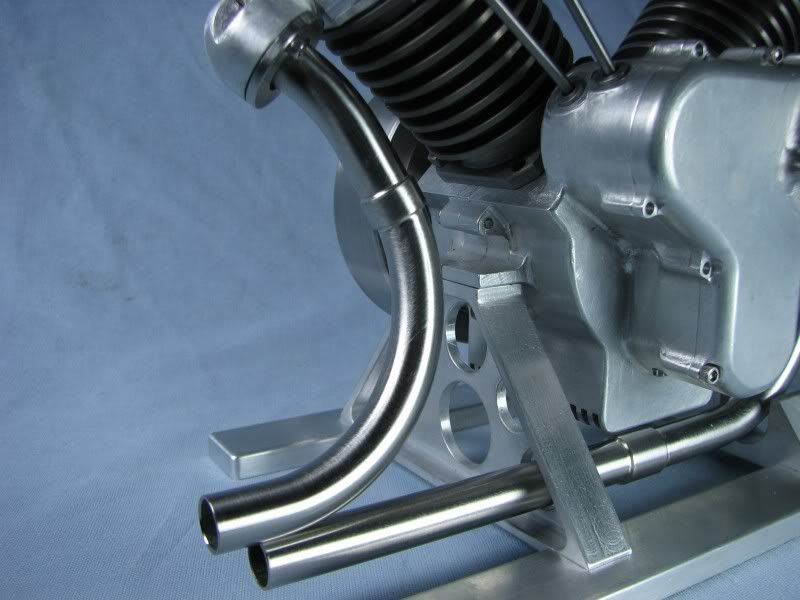

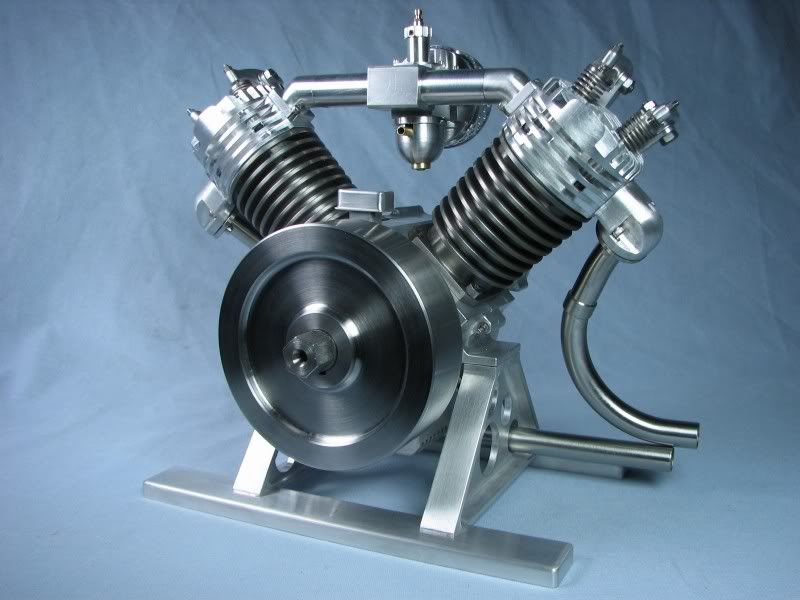

The rear pipe was completely different from the front one. I couldn't assemble it the same way because I wanted the rear pipe to locate above the extension of the front pipe. Had I used another 90 degree bend for the bottom it would have stuck out too far from the engine and stand the chance of being banged while moving the engine around.

I bent up a short piece for the upper pipe, silver soldered the retaining ring on it and bolted it in place. I then bent up another piece of pipe for the lower, this time going 135 degrees. I melted out the Cerro alloy and then started fitting. I set up a parallel to the height of the top of the front pipe as a gauge and kept nibbling away at the upper and lower pipes until I had a good lineup at the joint. Once satisfied with the fit I silver soldered them together. While soldering I added the extension pipe to the front exhaust tube. Everything was cleaned up and bolted together for some pictures. I might add that since I have my big lathe back in operation I cleaned up the flywheel and mounted it.

George

I bent up a short piece for the upper pipe, silver soldered the retaining ring on it and bolted it in place. I then bent up another piece of pipe for the lower, this time going 135 degrees. I melted out the Cerro alloy and then started fitting. I set up a parallel to the height of the top of the front pipe as a gauge and kept nibbling away at the upper and lower pipes until I had a good lineup at the joint. Once satisfied with the fit I silver soldered them together. While soldering I added the extension pipe to the front exhaust tube. Everything was cleaned up and bolted together for some pictures. I might add that since I have my big lathe back in operation I cleaned up the flywheel and mounted it.

George

crankshafter

Well-Known Member

- Joined

- Jul 17, 2007

- Messages

- 367

- Reaction score

- 24

George

BEAUTYFULL. you are real wizard George, wish I have a tiny % of your skills :bow: :bow:

Crankshafter.

BEAUTYFULL. you are real wizard George, wish I have a tiny % of your skills :bow: :bow:

Crankshafter.

- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

Unbelievable George!

It just gets better, and better!

Looks like you'll have it done for the N.A.M.E.S. show.?

-MB

It just gets better, and better!

Looks like you'll have it done for the N.A.M.E.S. show.?

-MB

- Joined

- Jul 16, 2007

- Messages

- 2,975

- Reaction score

- 1,043

Hi Rick, well it'll be done for the NAMES show. As with every engine I've ever built they don't start and run without tinkering out of the gate. It would be nice if it did but we'll have to wait and see. In any case I'll have it there, running or not.

George

George

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

I was actually worried that people wouldn't post for lack of something suitable to say.

I know I haven't had anything more suitable than 'awesome' for some time.

It's just wonderful work.

I know I haven't had anything more suitable than 'awesome' for some time.

It's just wonderful work.

gbritnell said:Hi Rick, well it'll be done for the NAMES show. As with every engine I've ever built they don't start and run without tinkering out of the gate. It would be nice if it did but we'll have to wait and see. In any case I'll have it there, running or not.

George

Oh cool. I hope to be there again this year. I can't wait to see it in person.

spuddevans

Well-Known Member

- Joined

- Feb 25, 2008

- Messages

- 204

- Reaction score

- 1

Absolutely stunning piece of engineering art. A beautiful engine that reflects well the creators skill.

Tim

Tim

zeeprogrammer said:I was actually worried that people wouldn't post for lack of something suitable to say.

you're right! watching at george's work is something that makes me mute, I stay without no more words

Similar threads

- Replies

- 61

- Views

- 8K