Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

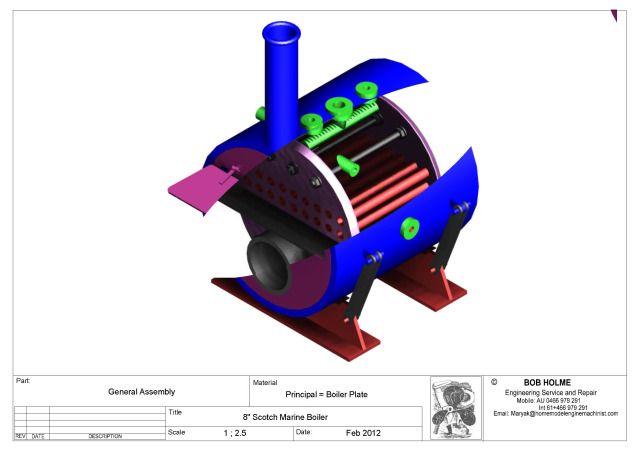

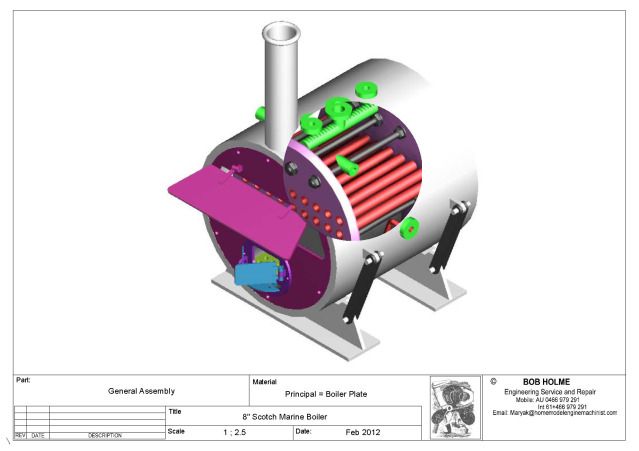

I keep threatening to build a boiler.

Well I've started to design one.

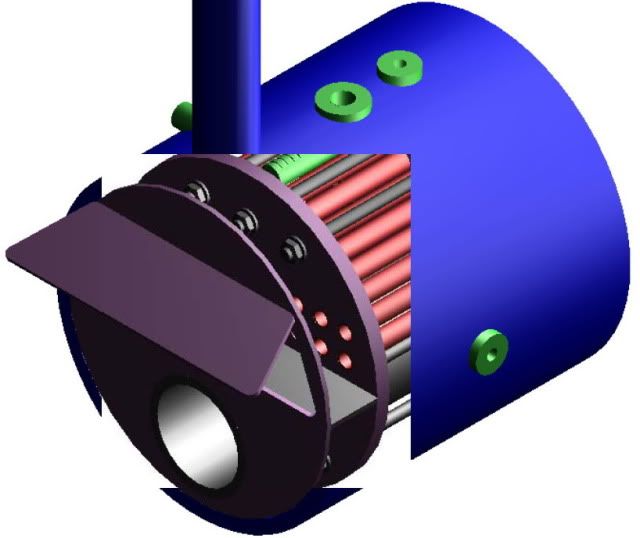

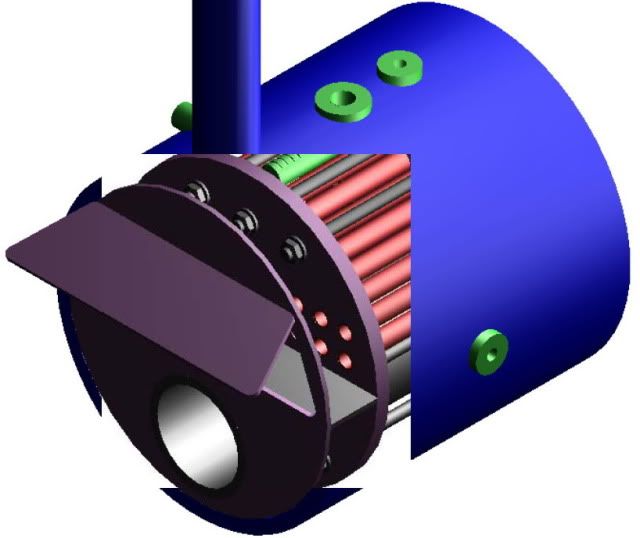

It's an 8" Dia Scotch boiler in Steel with copper tubes and a dry back.

At this point I've left the firing options open to either a spirit, (blowlamp) or coal.

Attached is an excel file covering the design parameters.

Best Regards

Bob

View attachment Boilercalc.xls

Well I've started to design one.

It's an 8" Dia Scotch boiler in Steel with copper tubes and a dry back.

At this point I've left the firing options open to either a spirit, (blowlamp) or coal.

Attached is an excel file covering the design parameters.

Best Regards

Bob

View attachment Boilercalc.xls