Hello all;

This write up deals with spindle removal and bearing replacement for Atlas 618

plain sleeve bearing lathes. It may come in handy for someone needing new

bearings, but the same procedure, (minus the bearing replacement) has to be

done if you simply need to replace the drive belt on the lathe, or if you need to

replace the thrust bearing, or step pulley bushings.

After getting my new/old lathe torn down, cleaned up, and put back together, I

made some test cuts to get a feel for the general health of the machine. It cuts

well, but when parting off, I can actually see lateral movement in the work piece,

and watching closely, I can pretty much tell it's from the old bearings.

I've had the spindle out of the lathe a few times already, and from looking in the

head stock bore with the spindle removed, I could see some scuffs on the front

sleeve bearing. I ordered new bearings from Clausing, and they showed up a few

days ago. They only took about a week to get here, counting a weekend. They

shipped the same day I ordered. Good service.

Today was a good day to get them put in so I can start seriously setting up this lathe.

I took pictures when I removed the spindle and put the new sleeve bearings in.

Some were taken when I first got the lathe, and it's pretty dirty. Some were taken

after everything had been washed in solvent. I had completely disassembled the

lathe, with the exception of the micro dials, which gave me a good idea of the shape

of things.

I figured some pictures and words might come in handy for other folks that may have this lathe.

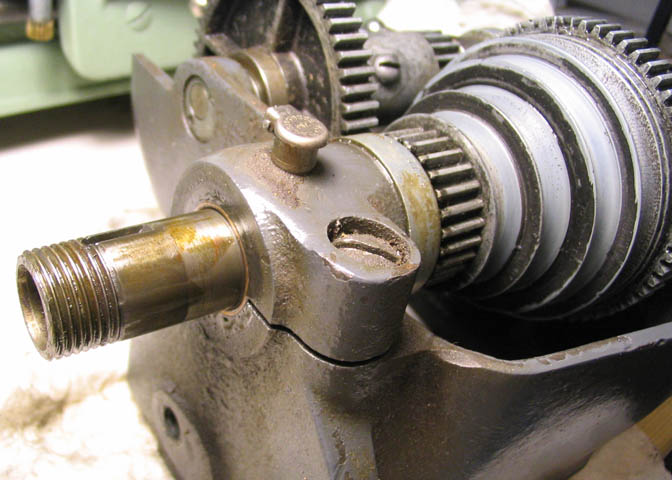

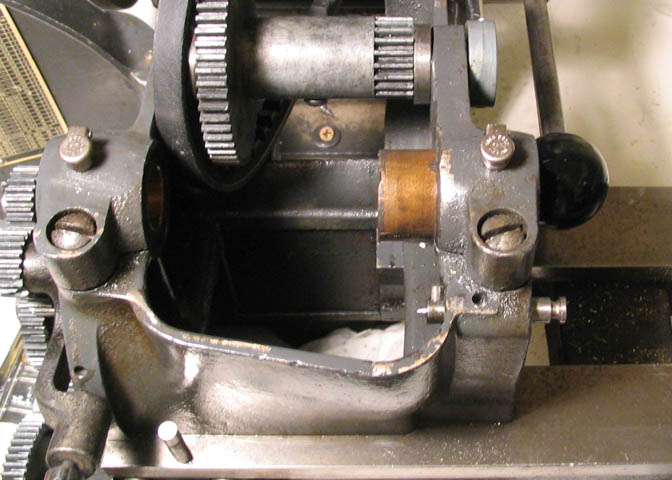

To start with, pull the power cord on the lathe. Remove the lock collar on the

back end of the spindle. In the shot above, it's already been removed. It has a

single set screw in it, so back it off a turn, and remove the collar. The collar is

round, and has no flats or anything to put a wrench on. I'm not going to tell you

to put pliers on it to remove it.. Go your own way on that. Some primate had

used a hard hammer on the back end of this spindle in the past, so the collar was

hard to remove. It is a right hand thread.

There is a soft BB in the bottom of the hole for the set screw so the screw doesn't

bur the threads on the end of the spindle. Don't loose it.

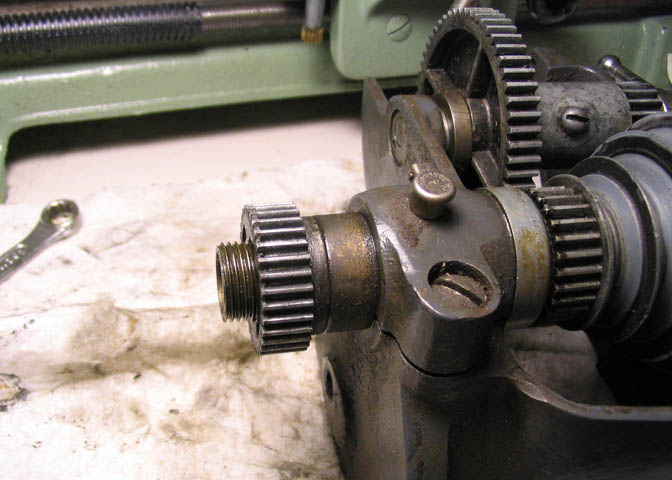

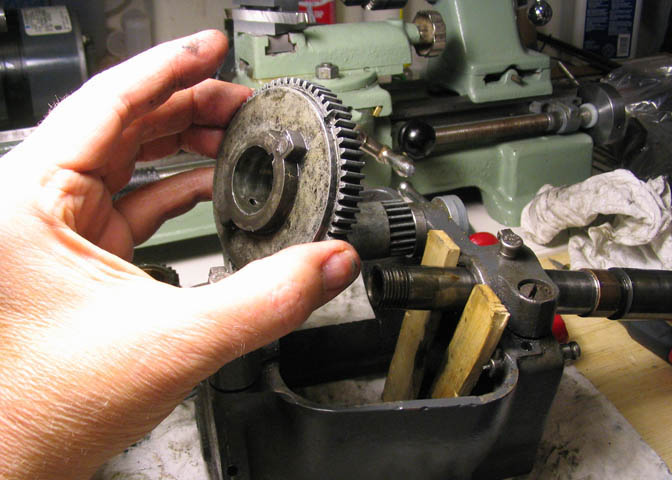

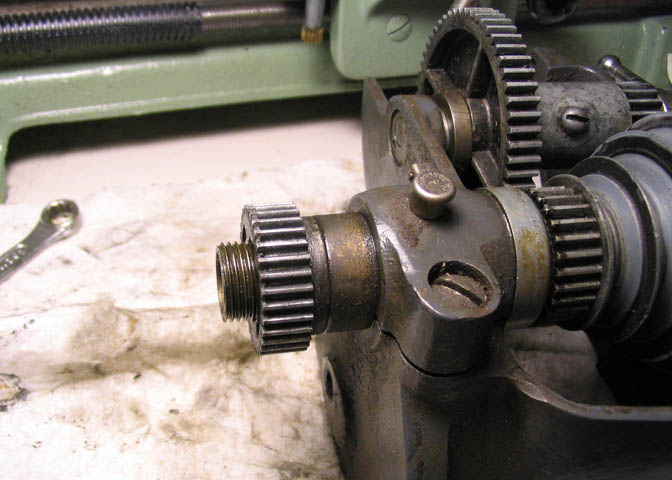

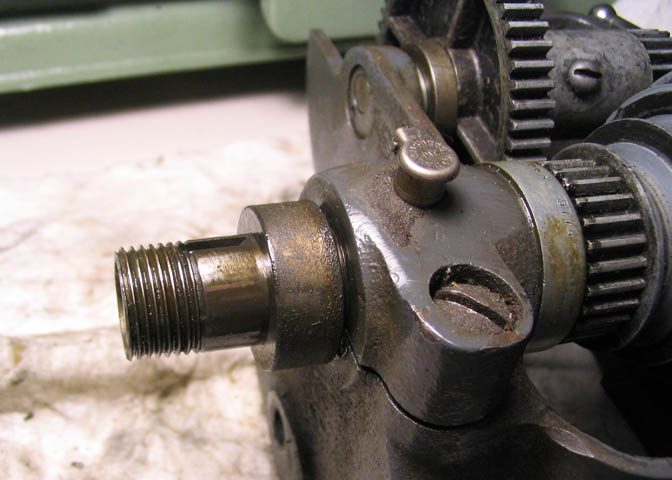

Then pull off the main spindle gear, and remove the Woodruff key.

After that, you can pull of this thrust collar.

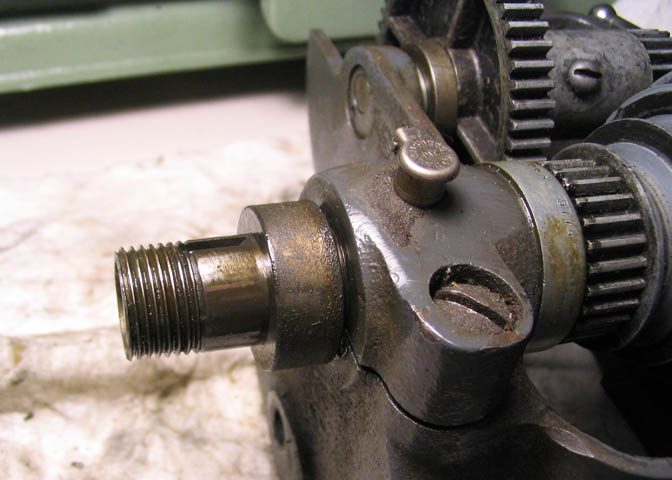

It should look like this when you have the pieces on the back end removed.

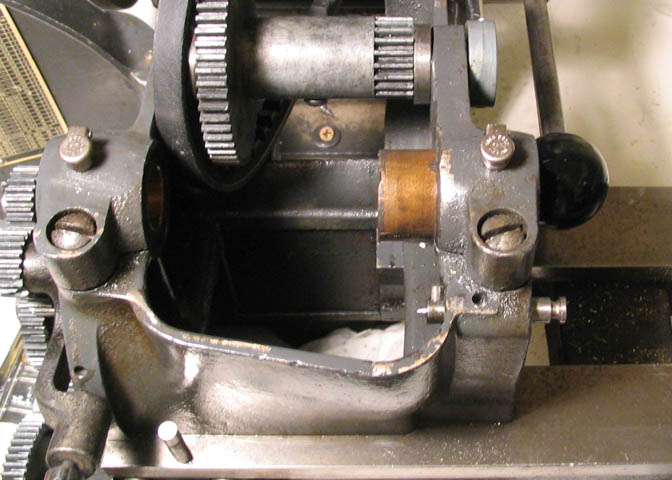

Now would be a good time to slack off the two big screws in the bearing caps.

You can see one of them in the picture above, and there is one on the chuck end

of the spindle, too. Back them off until they are loose, then just barely snug them

down. The idea is to get the spindle out without the bearings following it at the

same time.

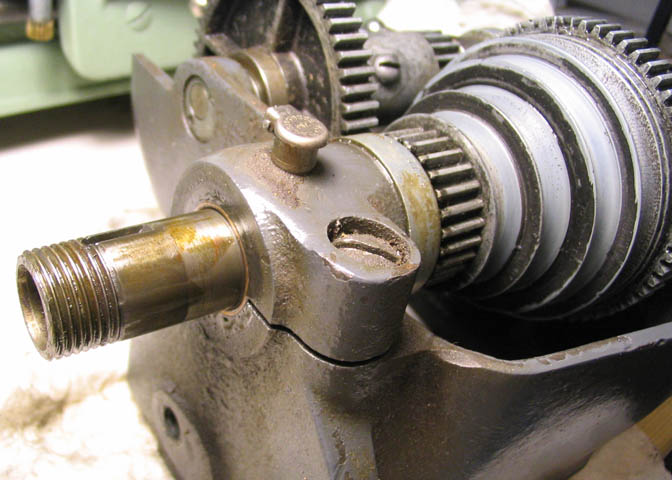

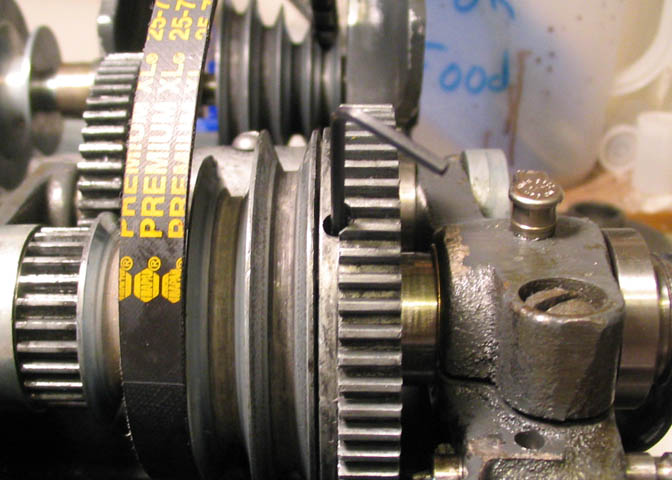

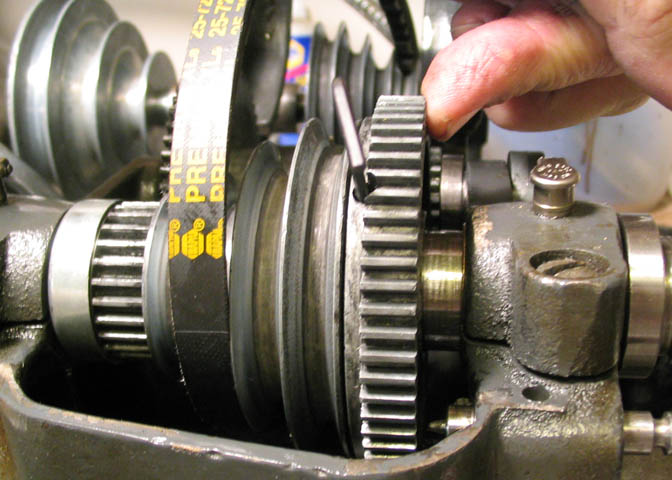

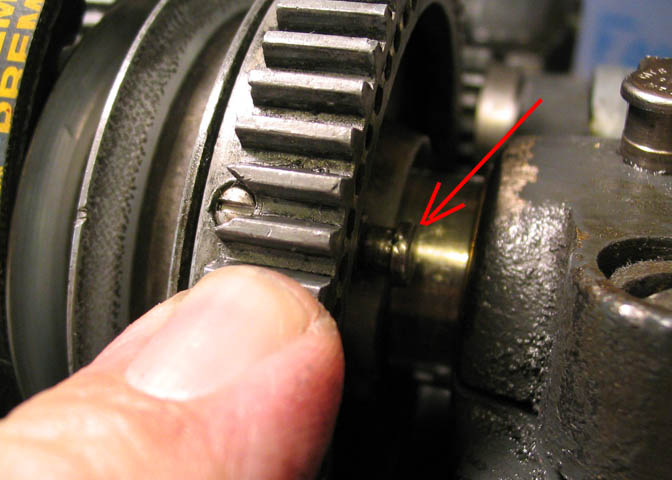

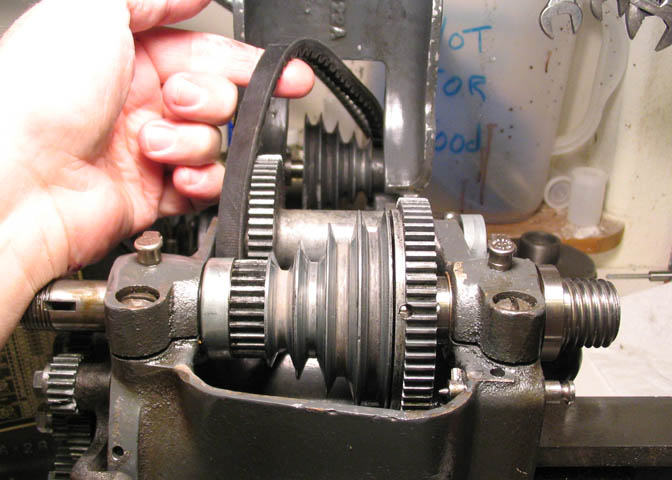

Now, get a look at the bull gear lock pin. Finding it is the easiest way to locate the

the lock screw for the bull gear. There is a screw at the edge of the bull gear in this

shot. That is for oil. Rotate the bull gear 180 degrees, and you will see another hole

opposite the oil hole just mentioned.

When you find the second bull gear hole, reach way down to the bottom of it with

a 5/64" allen wrench and loosen the set screw a couple of turns. That set screw is

only there to keep the bull gear from sliding along the spindle, but has to be loose to

get the spindle out.

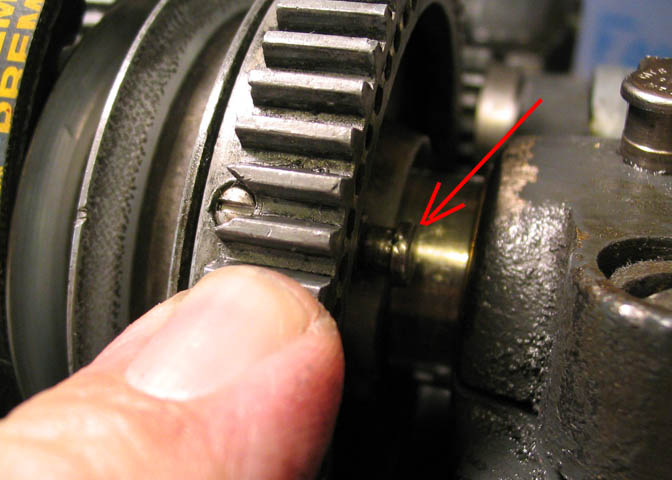

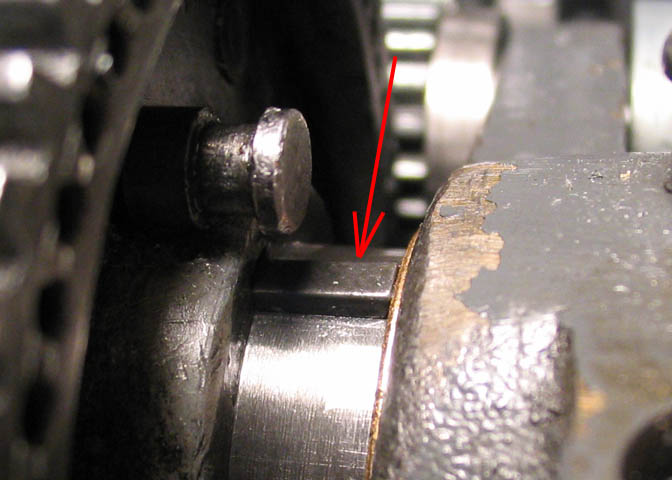

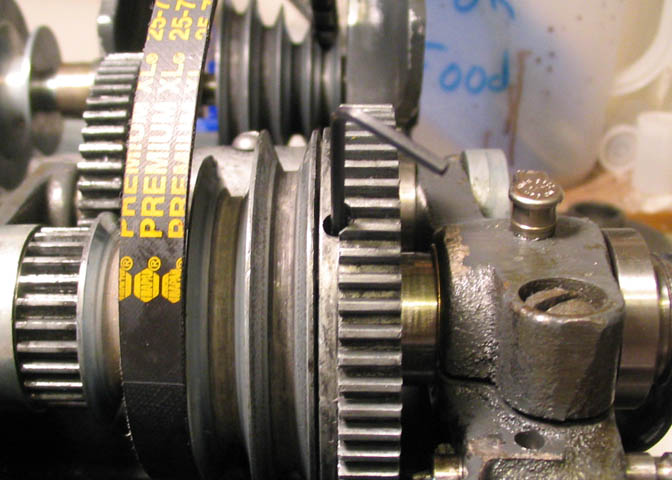

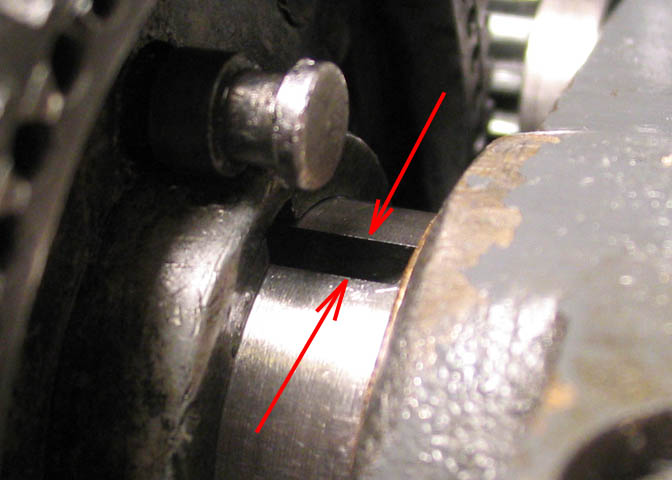

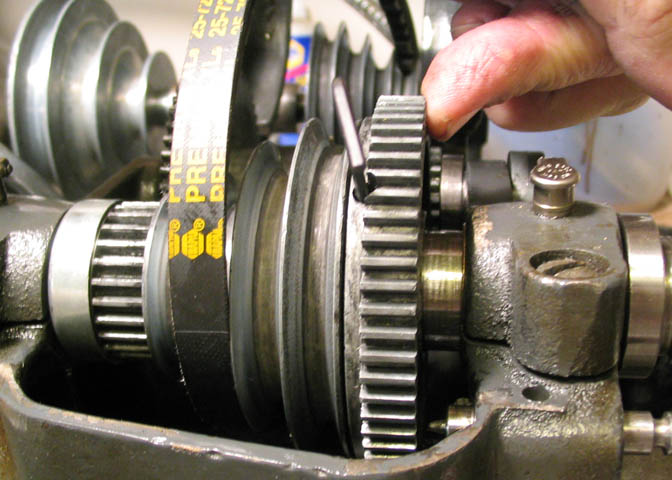

Now, unless there are other problems, (I'll save that for later), you should be able

to slide the spindle toward the tail stock. At this point, you only want to pull it out

of the nose end of the head stock about 3/8", until you can see the Woodruff key,

as in the picture above.

Take that key out, but don't pull the spindle any farther toward the tail stock end of

the lathe yet!

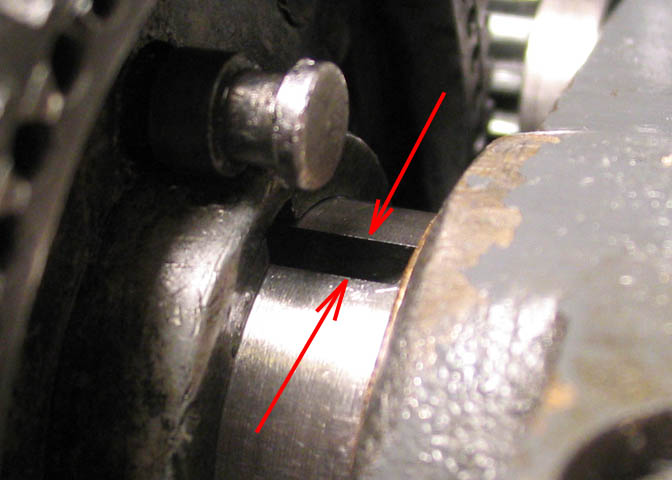

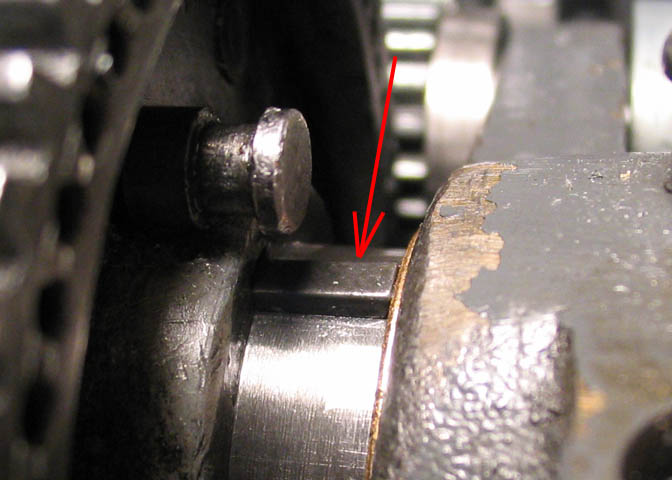

When the key is out, check very carefully at the corners and ends of the Woodruff

keyway. Use a fine file to gently remove any burs that you see. Then gently turn

the spindle 180 degrees and look for the place where the set screw in the bull gear

pinched on the spindle shaft. File that spot down too. These two places do not run

in the spindle bearings, so filing them won't hurt anything in that respect. The bull

gear sits over the top of both of these spots, and is always in the same relationship

to them, so there is no danger of the filing job doing any harm to it, either.

If you should just yard the spindle out of the head stock without doing the above, and

there are burs at these points, you'll score the bearings. I'm replacing the bearings right

now, but what if I just needed a belt? You have to take the spindle out to get a new belt

on too. You don't want to ruin your bearings just to replace a belt, so check these two

points carefully.

Once those burs are dressed down, reach in with a tissue and clean off any filings, and then

you can pull the spindle out slowly.

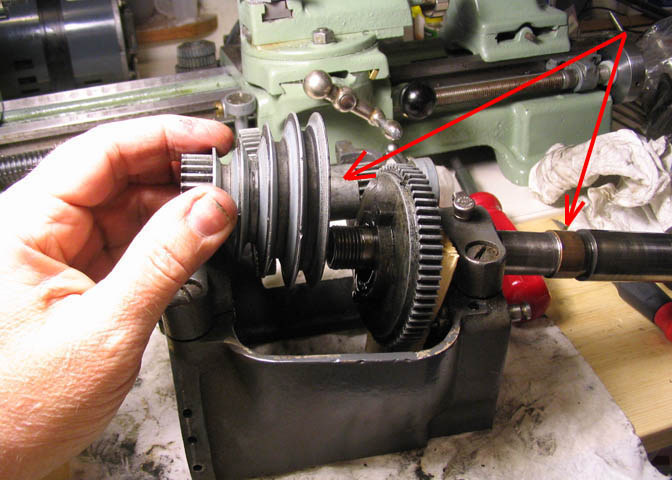

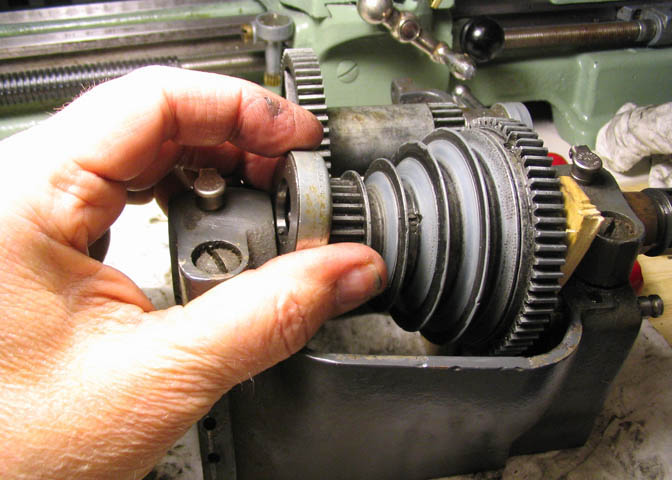

As you pull the spindle out, catch the thrust bearing. At about this point, the spindle

diameter will change at the nose end of the head stock. It gets smaller, so don't let

the spindle drop onto the bearing.

Note the small screw in the second pulley groove. That is for oil. Nothing else. It

lubes the step pulley bushings. (It's supposed to be oiled each day that you will use

the back gear.)

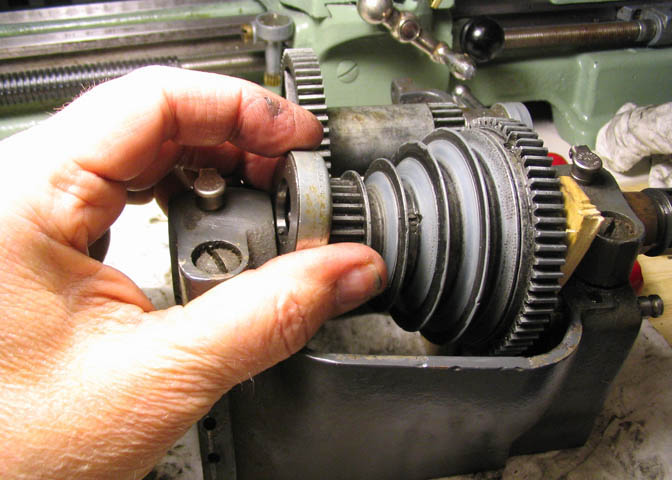

Keep pulling the spindle out, first grabbing the step pulley, then the bull gear, so they

don't fall down into the head stock cavity.

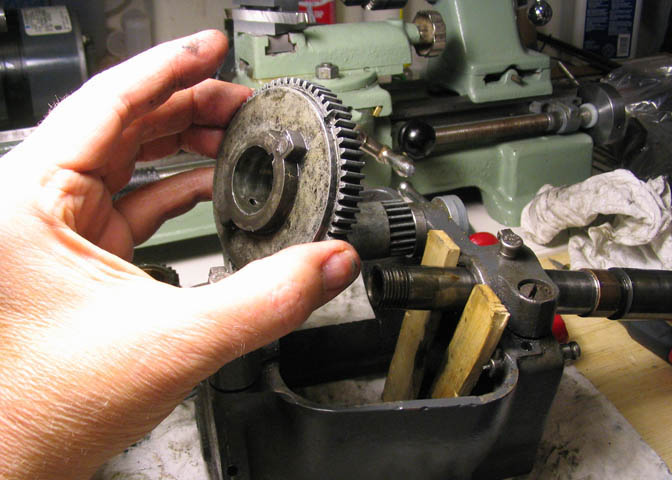

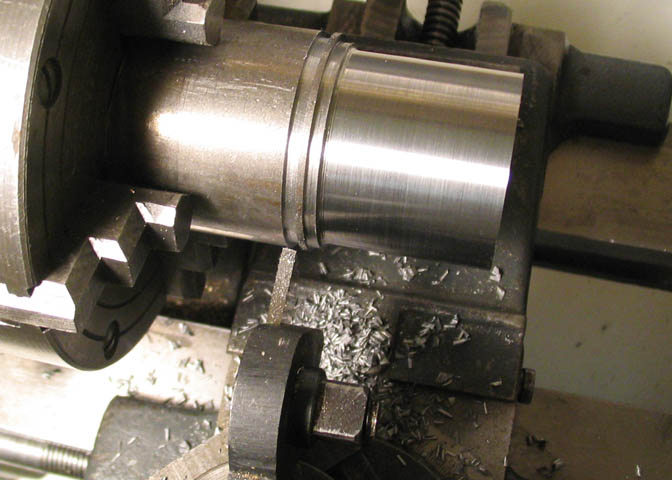

Now, I actually did have trouble with this one. The bushing you see on the

spindle in the shot above is supposed to stay in the step pulley. I had to tap

the spindle out with a piece of wood because the small bushing was stuck

on the spindle. There are two of those bushings, and they should both be

pressed into the step pulley. They allow the pulley to spin on the spindle

independant of the bull gear when you have the back gear engaged.

I soaked this for a while in solvent, and the bushing came off pretty easy. It was

pressed back into the step pulley, and all is well.

In this shot you can see what I'm talking about. That bushing on the spindle was

supposed to stay in the pulley.

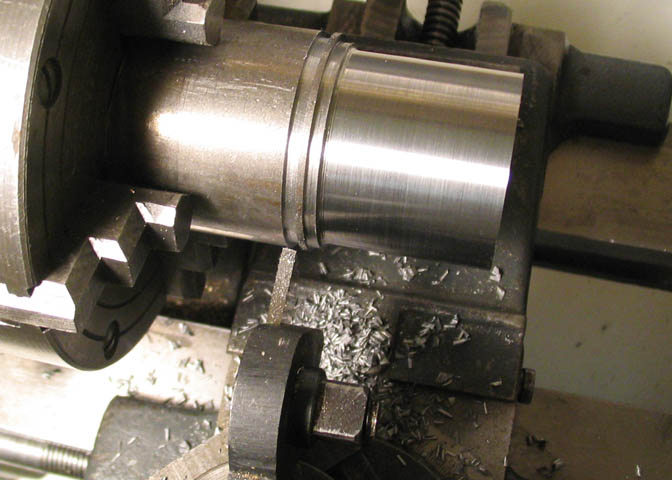

With the spindle nice and clean, I tried the new sleeve bearings to make sure

they were the right size, before I take out the old bearings. In this picture, the

tiny circle near the larger bearing is where the bull gear set screw has raised a

mark that I was talking about earlier, and this is one of the things that had to be

filed down before pulling the spindle through the bearings.

To get the old bearings out, make sure the bearing cap screws are loose, and

use a piece of wood or plastic to tap them toward the inside of the head stock.

Both the front (big) and rear (small) bearings would move a little by hard pressure

with my thumb, but I couldn't press far enough into the hole to get them all the

way out. So, tap, tap, with something soft.

Guess which one is the old bearing?

The old one, (ok, on the right!) still has factory paint on it, so it's been in there

a long time. You can see that it's taken a beating a few times too, by the marks

left from someone whacking on the end of the spindle without removing the

Woodruff key. I expect it's 50-60 years old. Reading on lathes/uk, it says there

were no more plain bearing lathes after around 1957-59, if I recall. So, it's done

it's job for a long time.

There are some straight marks in there that are no doubt from previous spindle removal,

but there is also a rather large spot of radial scuffing on the far right, which looks similar

to what you see sometimes in crank bearing shells in car engines. Many miles.

Putting the new bearings back in is just a matter of cleaning out the head stock, oiling the

outside of the bearings, and pushing them back in. If they seem a little tight, make sure

the bearing cap screw are loose first, then try again. If they are still too tight, try this, but

only if you really can't get them started straight without doing so;

Screw down the bearing cap screws until you feel them just barely start to get tight.

I'm talking about the point where you feel them touch the top of the hole as they

thread in, where if you screwed them in any further, they would start to squeeze the

bearing caps. (Don't screw them down hard. You'll break the caps.) Then back out

the screw just a touch, so it is free, like 1/20 of a turn. Use a thin wedge of wood, and

tap it into the parting line of the bearing cap to spread them just a thou or two. Be careful.

Don't hit the head stock casting with anything metal. Use a tiny plastic headed hammer

to tap in the wedge, and then just a little bit. This will spread the cap enough to let you

get the bearing started in the bore straight. Then you should be able to put a small piece

of wood on the end of the bearing and push it in with the palm of your hand. I had to

bump it in with the ball of my palm to get the big one in all the way. The small one went

easier. Then pull the wedge(s) out and make sure the cap screws are loose again.

Oil up the spindle with light oil, and put it back in the head stock to see that it fits without

any of the other gears/pulleys and other things. It should spin freely. Take it back out

and start putting all the parts on it as you feed it through the bearings, taking care not to

knock it on the bearings as you do so. Don't forget the Woodruff key that goes in the

bull gear.

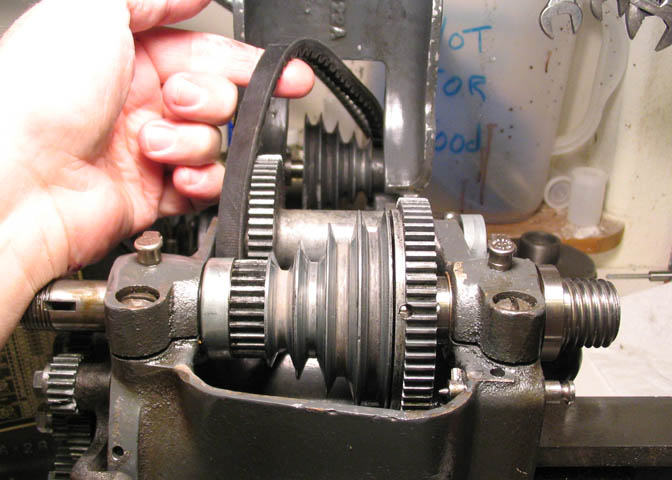

After you get it put back in, if you are me, you will immeadiatly take it back out

and put the belt on. If you are not me, you will put the belt on first!! I'm getting

pretty good at removing it, by now.

Put the belt on before you put on the thrust bearing...

When you have the spindle in, through the bull gear, step pulley, and thrust bearing,

replace the thrust collar on the back end, (the small end of the spindle), then the

main spindle gear and its' key, then screw on the lock collar.

Atlas says to run the collar up to the face of the spindle gear, then tighten it the space

of 1-2 teeth of the gear, rotating the spindle as you do so. They say it should have

some resistance, so when the spindle warms up it will not have any end play. Tighten

the lock screw on the collar, (make sure that the thread protecting BB is still in the hole).

Last step is to tighten the bull gear lock screw. Put the bull gear right up against

the step pulley, but not riding hard against it. The bull gear and the step pulley have

to be able to turn independently without rubbing against each other Tighten down

the bearing caps snug, but don't put all your might into it. Check to see that the

spindle still turns after tightening them.

To determine how tight to make these, I put a chuck on the spindle with a piece of

1 1/2" round stock sticking out about 2". Then put a DI on the back side of the round

stock, and pulled the stock toward the front of the lathe and then toward the back of

it and watched the readings. I tightened down the bearing caps until I had what I

wanted, which, for now, was about one thou at one inch from the chuck face. How

much you cinch down the caps is up to you, but I would say if you had to use all the

strength in one had on a screwdriver to get what you want, it may be too much. The

bearings caps are a pretty sturdy part of the casting, but they will only take so much!

I will say now, that this is just a guess derived from prior practical mechanical experience.

I'm no engineer. I couldn't find any solid info in the Atlas material available, and Clausing

didn't have a firm number for me as to torque when I called them for parts.

Sometimes, a practical test is the best indicator of how things are working. The oil

cups were filled with oil, set the lathe to one of its higher speeds, and let it run for a

half hour to get the bearings and spindle warmed up, keeping an eye on the oil cups

to make sure that they were oiling a bit. Also, every five minutes or so, I put a finger

on the bearing caps and the spindle nose, (lathe off!) to see if there was any undue

heating. They never got much over what I would call mildly warm, so the preload and

cap tension is probably good.

After warm up, I checked the spindle with the DI again, then tried a parting cut. The

tool was only run in about .050", but if it will do that without any chatter, I'll call it good.

Parting cuts are about the hardest thing on a lathe, outside of knurling, maybe, and if it

will part off without chatter, it should do fine.

Once the bearings have run in with a few hours of working time on them, I'll check the

run out again with the lathe warmed up, and make any adjustments I think it needs.

It's not likely I'll have to do this again in my lifetime, though if I'm lucky, I'll get to replace

a belt or two.

If you got through all this, thanks for having a look!

Dean

This write up deals with spindle removal and bearing replacement for Atlas 618

plain sleeve bearing lathes. It may come in handy for someone needing new

bearings, but the same procedure, (minus the bearing replacement) has to be

done if you simply need to replace the drive belt on the lathe, or if you need to

replace the thrust bearing, or step pulley bushings.

After getting my new/old lathe torn down, cleaned up, and put back together, I

made some test cuts to get a feel for the general health of the machine. It cuts

well, but when parting off, I can actually see lateral movement in the work piece,

and watching closely, I can pretty much tell it's from the old bearings.

I've had the spindle out of the lathe a few times already, and from looking in the

head stock bore with the spindle removed, I could see some scuffs on the front

sleeve bearing. I ordered new bearings from Clausing, and they showed up a few

days ago. They only took about a week to get here, counting a weekend. They

shipped the same day I ordered. Good service.

Today was a good day to get them put in so I can start seriously setting up this lathe.

I took pictures when I removed the spindle and put the new sleeve bearings in.

Some were taken when I first got the lathe, and it's pretty dirty. Some were taken

after everything had been washed in solvent. I had completely disassembled the

lathe, with the exception of the micro dials, which gave me a good idea of the shape

of things.

I figured some pictures and words might come in handy for other folks that may have this lathe.

To start with, pull the power cord on the lathe. Remove the lock collar on the

back end of the spindle. In the shot above, it's already been removed. It has a

single set screw in it, so back it off a turn, and remove the collar. The collar is

round, and has no flats or anything to put a wrench on. I'm not going to tell you

to put pliers on it to remove it.. Go your own way on that. Some primate had

used a hard hammer on the back end of this spindle in the past, so the collar was

hard to remove. It is a right hand thread.

There is a soft BB in the bottom of the hole for the set screw so the screw doesn't

bur the threads on the end of the spindle. Don't loose it.

Then pull off the main spindle gear, and remove the Woodruff key.

After that, you can pull of this thrust collar.

It should look like this when you have the pieces on the back end removed.

Now would be a good time to slack off the two big screws in the bearing caps.

You can see one of them in the picture above, and there is one on the chuck end

of the spindle, too. Back them off until they are loose, then just barely snug them

down. The idea is to get the spindle out without the bearings following it at the

same time.

Now, get a look at the bull gear lock pin. Finding it is the easiest way to locate the

the lock screw for the bull gear. There is a screw at the edge of the bull gear in this

shot. That is for oil. Rotate the bull gear 180 degrees, and you will see another hole

opposite the oil hole just mentioned.

When you find the second bull gear hole, reach way down to the bottom of it with

a 5/64" allen wrench and loosen the set screw a couple of turns. That set screw is

only there to keep the bull gear from sliding along the spindle, but has to be loose to

get the spindle out.

Now, unless there are other problems, (I'll save that for later), you should be able

to slide the spindle toward the tail stock. At this point, you only want to pull it out

of the nose end of the head stock about 3/8", until you can see the Woodruff key,

as in the picture above.

Take that key out, but don't pull the spindle any farther toward the tail stock end of

the lathe yet!

When the key is out, check very carefully at the corners and ends of the Woodruff

keyway. Use a fine file to gently remove any burs that you see. Then gently turn

the spindle 180 degrees and look for the place where the set screw in the bull gear

pinched on the spindle shaft. File that spot down too. These two places do not run

in the spindle bearings, so filing them won't hurt anything in that respect. The bull

gear sits over the top of both of these spots, and is always in the same relationship

to them, so there is no danger of the filing job doing any harm to it, either.

If you should just yard the spindle out of the head stock without doing the above, and

there are burs at these points, you'll score the bearings. I'm replacing the bearings right

now, but what if I just needed a belt? You have to take the spindle out to get a new belt

on too. You don't want to ruin your bearings just to replace a belt, so check these two

points carefully.

Once those burs are dressed down, reach in with a tissue and clean off any filings, and then

you can pull the spindle out slowly.

As you pull the spindle out, catch the thrust bearing. At about this point, the spindle

diameter will change at the nose end of the head stock. It gets smaller, so don't let

the spindle drop onto the bearing.

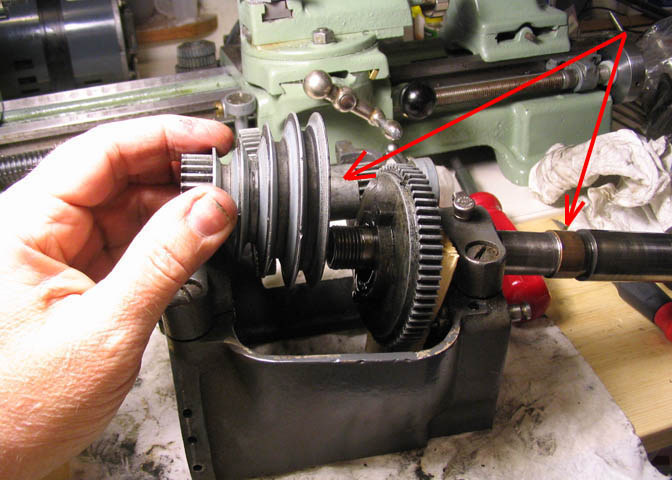

Note the small screw in the second pulley groove. That is for oil. Nothing else. It

lubes the step pulley bushings. (It's supposed to be oiled each day that you will use

the back gear.)

Keep pulling the spindle out, first grabbing the step pulley, then the bull gear, so they

don't fall down into the head stock cavity.

Now, I actually did have trouble with this one. The bushing you see on the

spindle in the shot above is supposed to stay in the step pulley. I had to tap

the spindle out with a piece of wood because the small bushing was stuck

on the spindle. There are two of those bushings, and they should both be

pressed into the step pulley. They allow the pulley to spin on the spindle

independant of the bull gear when you have the back gear engaged.

I soaked this for a while in solvent, and the bushing came off pretty easy. It was

pressed back into the step pulley, and all is well.

In this shot you can see what I'm talking about. That bushing on the spindle was

supposed to stay in the pulley.

With the spindle nice and clean, I tried the new sleeve bearings to make sure

they were the right size, before I take out the old bearings. In this picture, the

tiny circle near the larger bearing is where the bull gear set screw has raised a

mark that I was talking about earlier, and this is one of the things that had to be

filed down before pulling the spindle through the bearings.

To get the old bearings out, make sure the bearing cap screws are loose, and

use a piece of wood or plastic to tap them toward the inside of the head stock.

Both the front (big) and rear (small) bearings would move a little by hard pressure

with my thumb, but I couldn't press far enough into the hole to get them all the

way out. So, tap, tap, with something soft.

Guess which one is the old bearing?

The old one, (ok, on the right!) still has factory paint on it, so it's been in there

a long time. You can see that it's taken a beating a few times too, by the marks

left from someone whacking on the end of the spindle without removing the

Woodruff key. I expect it's 50-60 years old. Reading on lathes/uk, it says there

were no more plain bearing lathes after around 1957-59, if I recall. So, it's done

it's job for a long time.

There are some straight marks in there that are no doubt from previous spindle removal,

but there is also a rather large spot of radial scuffing on the far right, which looks similar

to what you see sometimes in crank bearing shells in car engines. Many miles.

Putting the new bearings back in is just a matter of cleaning out the head stock, oiling the

outside of the bearings, and pushing them back in. If they seem a little tight, make sure

the bearing cap screw are loose first, then try again. If they are still too tight, try this, but

only if you really can't get them started straight without doing so;

Screw down the bearing cap screws until you feel them just barely start to get tight.

I'm talking about the point where you feel them touch the top of the hole as they

thread in, where if you screwed them in any further, they would start to squeeze the

bearing caps. (Don't screw them down hard. You'll break the caps.) Then back out

the screw just a touch, so it is free, like 1/20 of a turn. Use a thin wedge of wood, and

tap it into the parting line of the bearing cap to spread them just a thou or two. Be careful.

Don't hit the head stock casting with anything metal. Use a tiny plastic headed hammer

to tap in the wedge, and then just a little bit. This will spread the cap enough to let you

get the bearing started in the bore straight. Then you should be able to put a small piece

of wood on the end of the bearing and push it in with the palm of your hand. I had to

bump it in with the ball of my palm to get the big one in all the way. The small one went

easier. Then pull the wedge(s) out and make sure the cap screws are loose again.

Oil up the spindle with light oil, and put it back in the head stock to see that it fits without

any of the other gears/pulleys and other things. It should spin freely. Take it back out

and start putting all the parts on it as you feed it through the bearings, taking care not to

knock it on the bearings as you do so. Don't forget the Woodruff key that goes in the

bull gear.

After you get it put back in, if you are me, you will immeadiatly take it back out

and put the belt on. If you are not me, you will put the belt on first!! I'm getting

pretty good at removing it, by now.

Put the belt on before you put on the thrust bearing...

When you have the spindle in, through the bull gear, step pulley, and thrust bearing,

replace the thrust collar on the back end, (the small end of the spindle), then the

main spindle gear and its' key, then screw on the lock collar.

Atlas says to run the collar up to the face of the spindle gear, then tighten it the space

of 1-2 teeth of the gear, rotating the spindle as you do so. They say it should have

some resistance, so when the spindle warms up it will not have any end play. Tighten

the lock screw on the collar, (make sure that the thread protecting BB is still in the hole).

Last step is to tighten the bull gear lock screw. Put the bull gear right up against

the step pulley, but not riding hard against it. The bull gear and the step pulley have

to be able to turn independently without rubbing against each other Tighten down

the bearing caps snug, but don't put all your might into it. Check to see that the

spindle still turns after tightening them.

To determine how tight to make these, I put a chuck on the spindle with a piece of

1 1/2" round stock sticking out about 2". Then put a DI on the back side of the round

stock, and pulled the stock toward the front of the lathe and then toward the back of

it and watched the readings. I tightened down the bearing caps until I had what I

wanted, which, for now, was about one thou at one inch from the chuck face. How

much you cinch down the caps is up to you, but I would say if you had to use all the

strength in one had on a screwdriver to get what you want, it may be too much. The

bearings caps are a pretty sturdy part of the casting, but they will only take so much!

I will say now, that this is just a guess derived from prior practical mechanical experience.

I'm no engineer. I couldn't find any solid info in the Atlas material available, and Clausing

didn't have a firm number for me as to torque when I called them for parts.

Sometimes, a practical test is the best indicator of how things are working. The oil

cups were filled with oil, set the lathe to one of its higher speeds, and let it run for a

half hour to get the bearings and spindle warmed up, keeping an eye on the oil cups

to make sure that they were oiling a bit. Also, every five minutes or so, I put a finger

on the bearing caps and the spindle nose, (lathe off!) to see if there was any undue

heating. They never got much over what I would call mildly warm, so the preload and

cap tension is probably good.

After warm up, I checked the spindle with the DI again, then tried a parting cut. The

tool was only run in about .050", but if it will do that without any chatter, I'll call it good.

Parting cuts are about the hardest thing on a lathe, outside of knurling, maybe, and if it

will part off without chatter, it should do fine.

Once the bearings have run in with a few hours of working time on them, I'll check the

run out again with the lathe warmed up, and make any adjustments I think it needs.

It's not likely I'll have to do this again in my lifetime, though if I'm lucky, I'll get to replace

a belt or two.

If you got through all this, thanks for having a look!

Dean