Alibre works just fine under XP 32 bit.

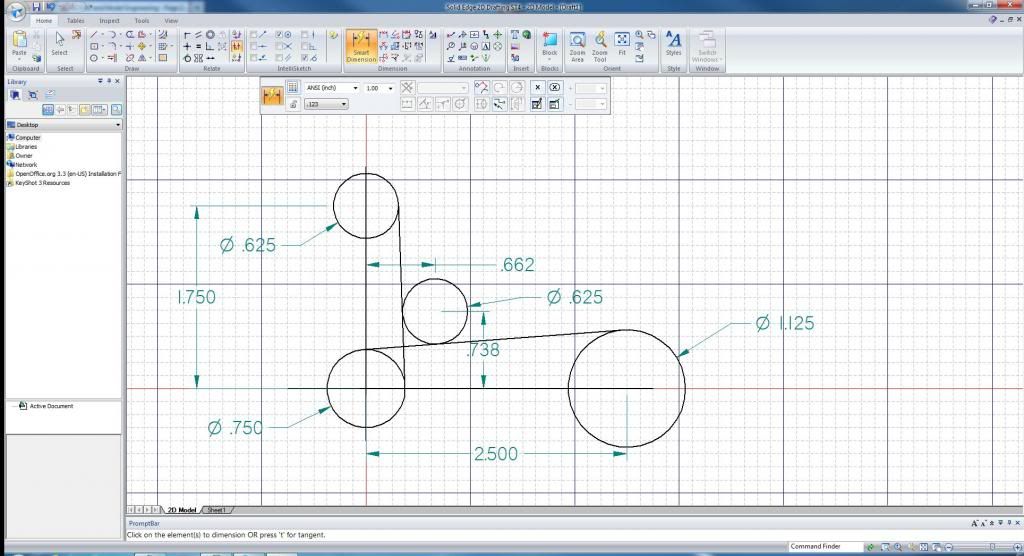

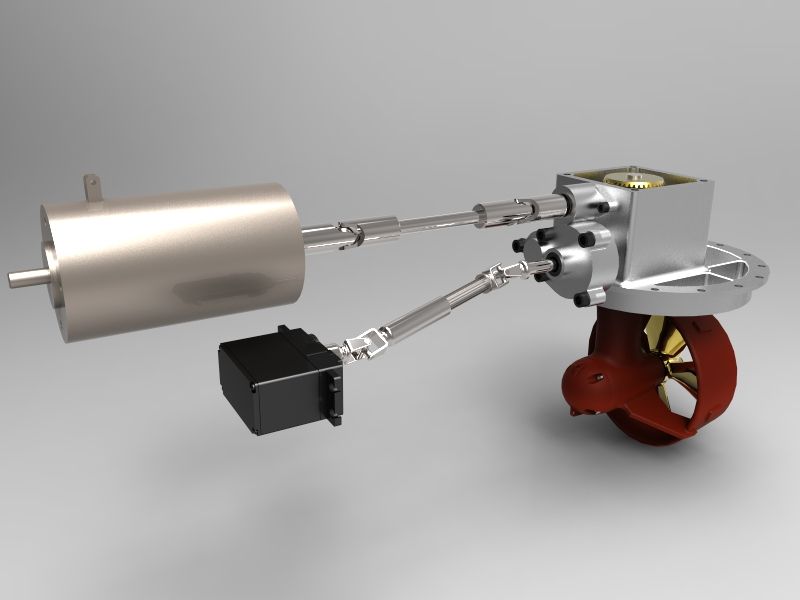

I switched from AutoCAD to Alibre after the second issue of my magazine. I could not do the drawings if I had to use a 2D drafting tool to make them. Alibre is about 10 x faster than 2D and being able to put all the parts together and check clearances, etc., is incredibly important. Motion capabilities really allow analysis of designs, etc. Especially when tab A hits tab B and it should have hit tab C. Really keeps the errata notifications to a minimum.

It is also a major design tool where I feel 2D is just a drafting tool.