Baner

Active Member

Almost done!

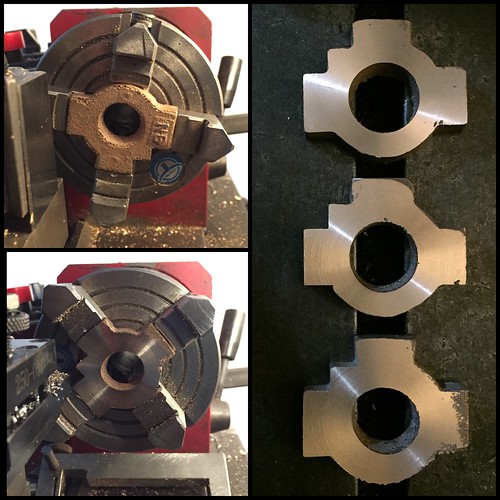

I don't need the chucking piece on the pump anymore so that gets parted off and cleaned up:

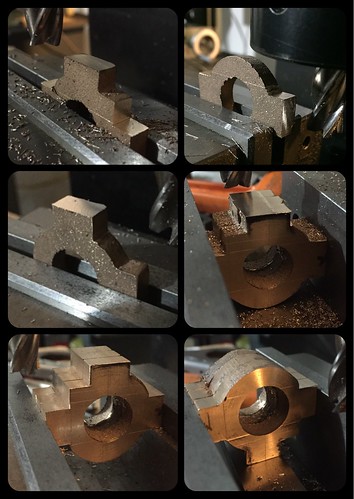

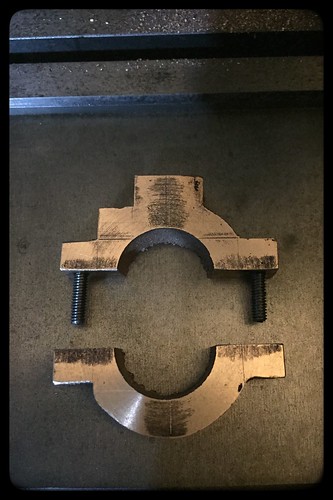

I need a lock nut to clamp the pump to the stay. I didn't have the right sized Hex bar so a stub of 3/4 round goes to the rotary table and get milled into shape. Then to the lathe and finished off:

All that's left is to form the ball seats, (the balls have yet to arrive) clean up a bit and I'll probably paint the leftover raw cast areas. Here it is installed in the chassis:

Dave.

I don't need the chucking piece on the pump anymore so that gets parted off and cleaned up:

I need a lock nut to clamp the pump to the stay. I didn't have the right sized Hex bar so a stub of 3/4 round goes to the rotary table and get milled into shape. Then to the lathe and finished off:

All that's left is to form the ball seats, (the balls have yet to arrive) clean up a bit and I'll probably paint the leftover raw cast areas. Here it is installed in the chassis:

Dave.

Last edited:

Northumbrian

Northumbrian Northumbrian

Northumbrian Northumbrian

Northumbrian Northumbrian

Northumbrian Northumbrian

Northumbrian Northumbrian

Northumbrian Northumbrian

Northumbrian Northumbrian

Northumbrian Northumbrian

Northumbrian Northumbrian

Northumbrian Northumbrian

Northumbrian Northumbrian

Northumbrian Northumbrian

Northumbrian Northumbrian

Northumbrian Northumbrian

Northumbrian Northumbrian

Northumbrian Northumbrian

Northumbrian