Hello engine builders,

A few years ago i made the 2 stroke debbie engine from Jan Ridder but never get it to work.

This project: https://www.homemodelenginemachinist.com/threads/2-stroke-debbie.24576/

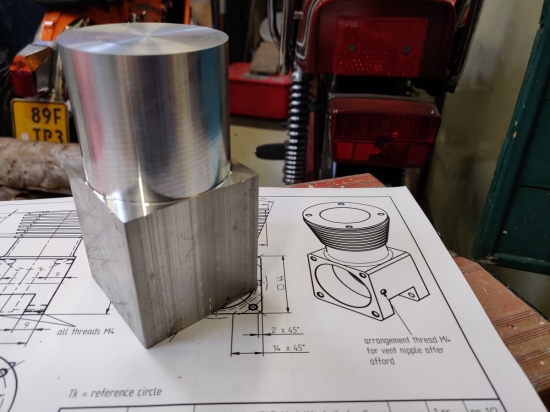

This weekend i started a new project. Im going to try to build a 4 stoke engine. I just bought building plans from http://www.cad-modelltechnik-jung.de Its a well documented build plan.

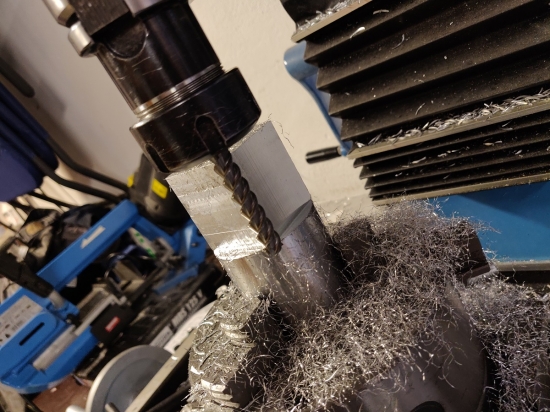

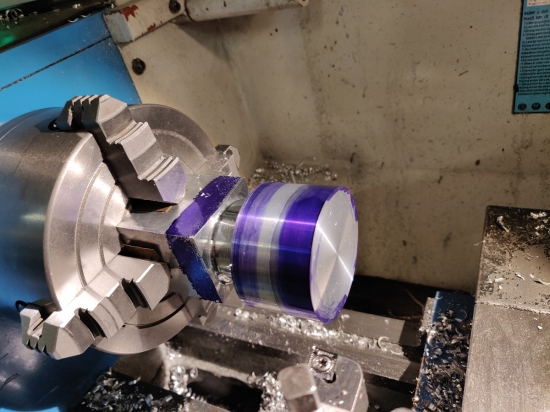

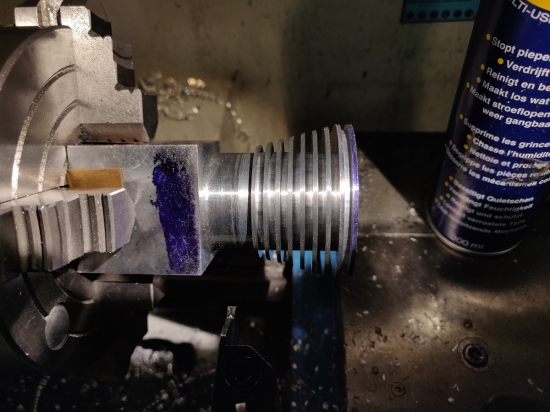

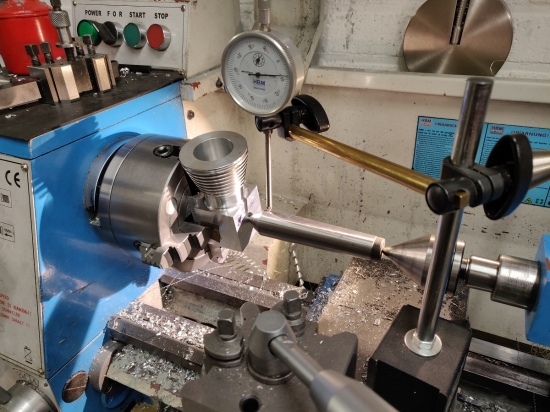

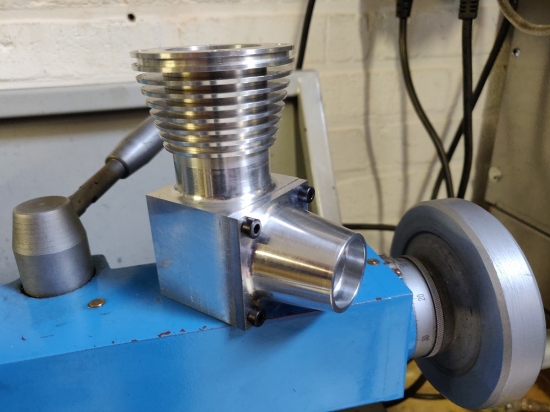

This weekend I machined the main body here are some pictures of it:

stef

A few years ago i made the 2 stroke debbie engine from Jan Ridder but never get it to work.

This project: https://www.homemodelenginemachinist.com/threads/2-stroke-debbie.24576/

This weekend i started a new project. Im going to try to build a 4 stoke engine. I just bought building plans from http://www.cad-modelltechnik-jung.de Its a well documented build plan.

This weekend I machined the main body here are some pictures of it:

stef

![550-OAR:%20cache[DIR]albums[DIR]modelbouw[DIR]17cc_4_stroke[DIR]IMG_20190209_125816.jpg](https://proxy.imagearchive.com/369/36976f9ee615cdec52ab6e110616ed5b.jpg)

![550-OAR:%20cache[DIR]albums[DIR]modelbouw[DIR]17cc_4_stroke[DIR]IMG_20190209_125822.jpg](https://proxy.imagearchive.com/bd6/bd68d1267e389d2d6dfcb1e9f1d4d3f6.jpg)

![550-OAR:%20cache[DIR]albums[DIR]modelbouw[DIR]17cc_4_stroke[DIR]IMG_20190209_162700.jpg](https://proxy.imagearchive.com/1bb/1bb1d7fc3dd70bccca69277e687bd2e8.jpg)

![550-OAR:%20cache[DIR]albums[DIR]modelbouw[DIR]17cc_4_stroke[DIR]IMG_20190209_184736.jpg](https://proxy.imagearchive.com/323/323a7b30253ec1a46b12db179ac8c30a.jpg)

![550-OAR:%20cache[DIR]albums[DIR]modelbouw[DIR]17cc_4_stroke[DIR]IMG_20190209_192753.jpg](https://proxy.imagearchive.com/19a/19abe141ddc0d0cb28349b505e80515f.jpg)

![550-OAR:%20cache[DIR]albums[DIR]modelbouw[DIR]17cc_4_stroke[DIR]IMG_20190209_202039.jpg](https://proxy.imagearchive.com/3d0/3d0efee71952d47da86c65adcf4455b0.jpg)

![550-OAR:%20cache[DIR]albums[DIR]modelbouw[DIR]17cc_4_stroke[DIR]IMG_20190209_211025.jpg](https://proxy.imagearchive.com/291/29102d33c2d630b81155acd710f5588f.jpg)