rodw

Well-Known Member

- Joined

- Dec 2, 2012

- Messages

- 1,146

- Reaction score

- 340

Thanks guys.

Yes the earlier link never worked as it must be to old, but I found it on ebay easily enough.

Another question If I buy say a 30 amp one which are only around $20 Australian can I use a smaller amp power supply, or would I be better off with a 15 amp or less.

Sorry for the questions, I can confidently wire cars, houses etc, but when it come to fine electronics I get lost.

Dave

Dave,

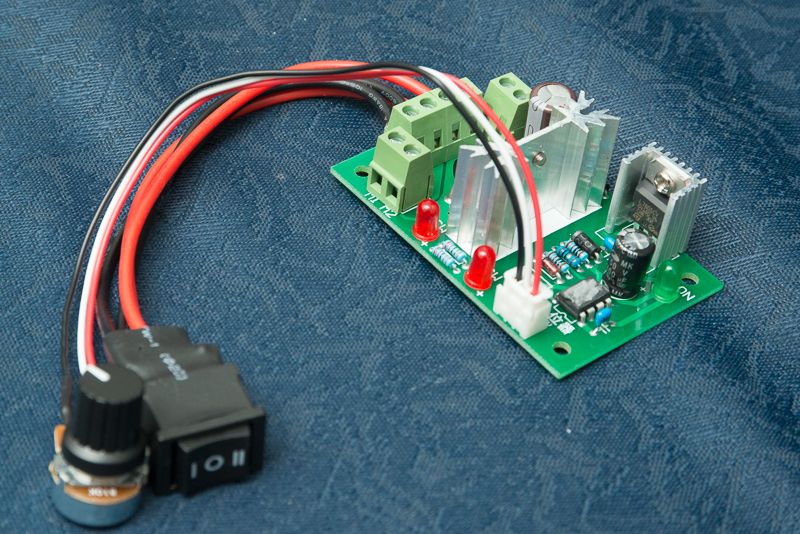

Here's what I dug out of my drill for you

The controller is marked a maximum of 7 amps for what it is worth and I am hoping to get away with 3.5 amps.

And a close up of my clutch set up to drive the leadscrew.

Unfortunately the belt I have is not long enough and Gates in Australia were no help match this up to anything so I am going to use a flexible drive shaft so the motor can be misaligned.

So my question is, do you think you could cut the flexible shaft in half and silver solder it into a hole in some brass or 12L14?