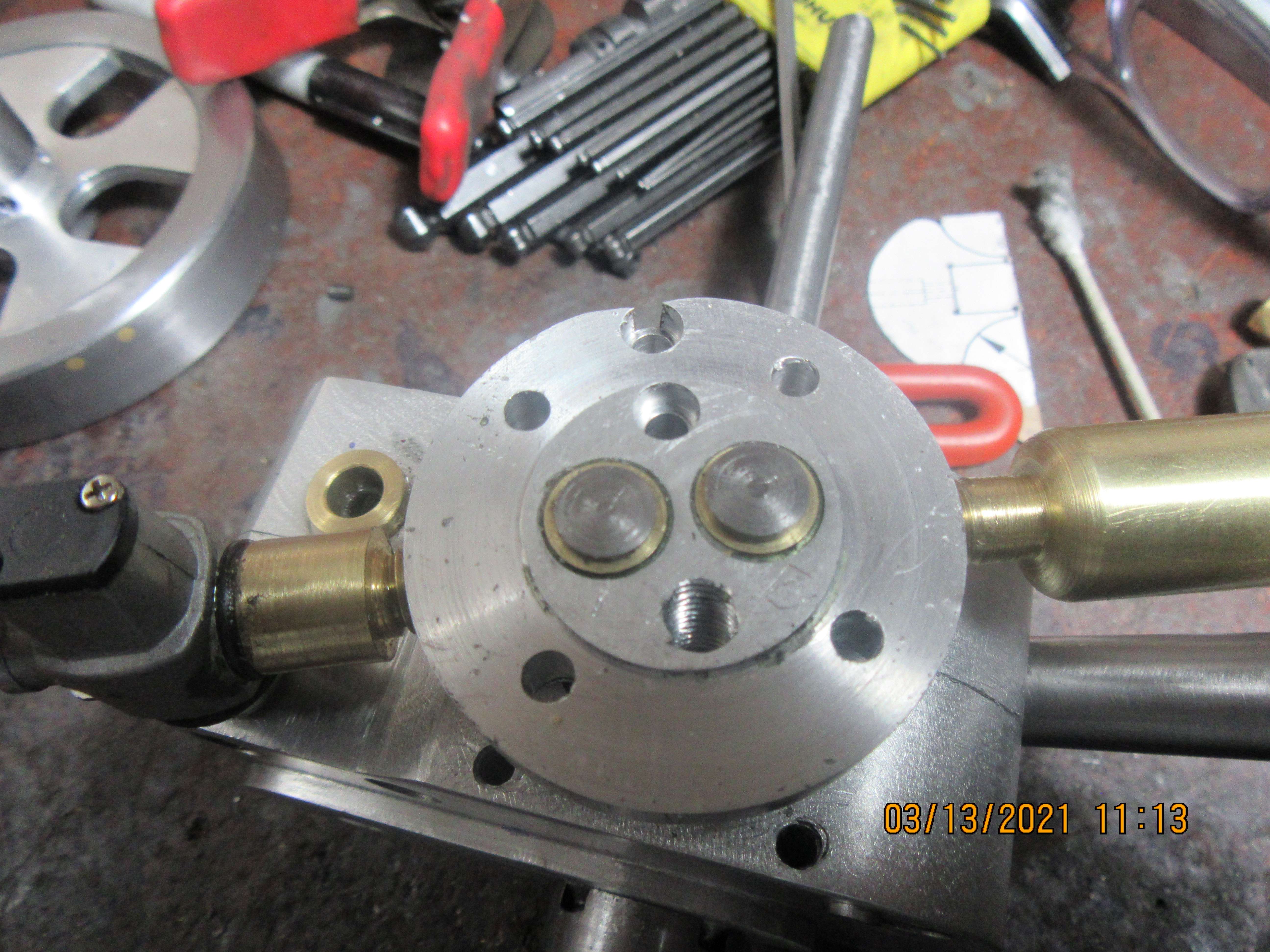

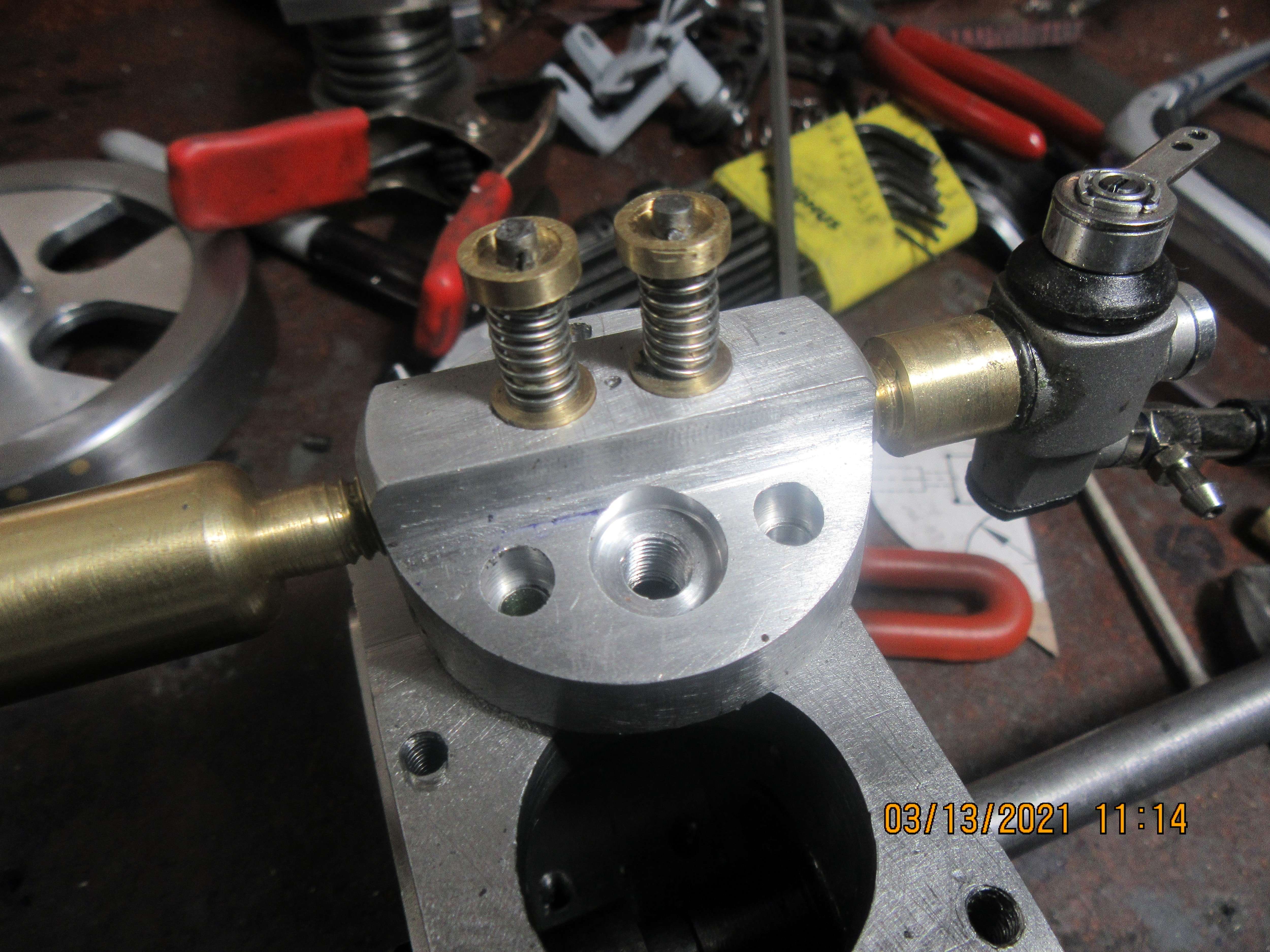

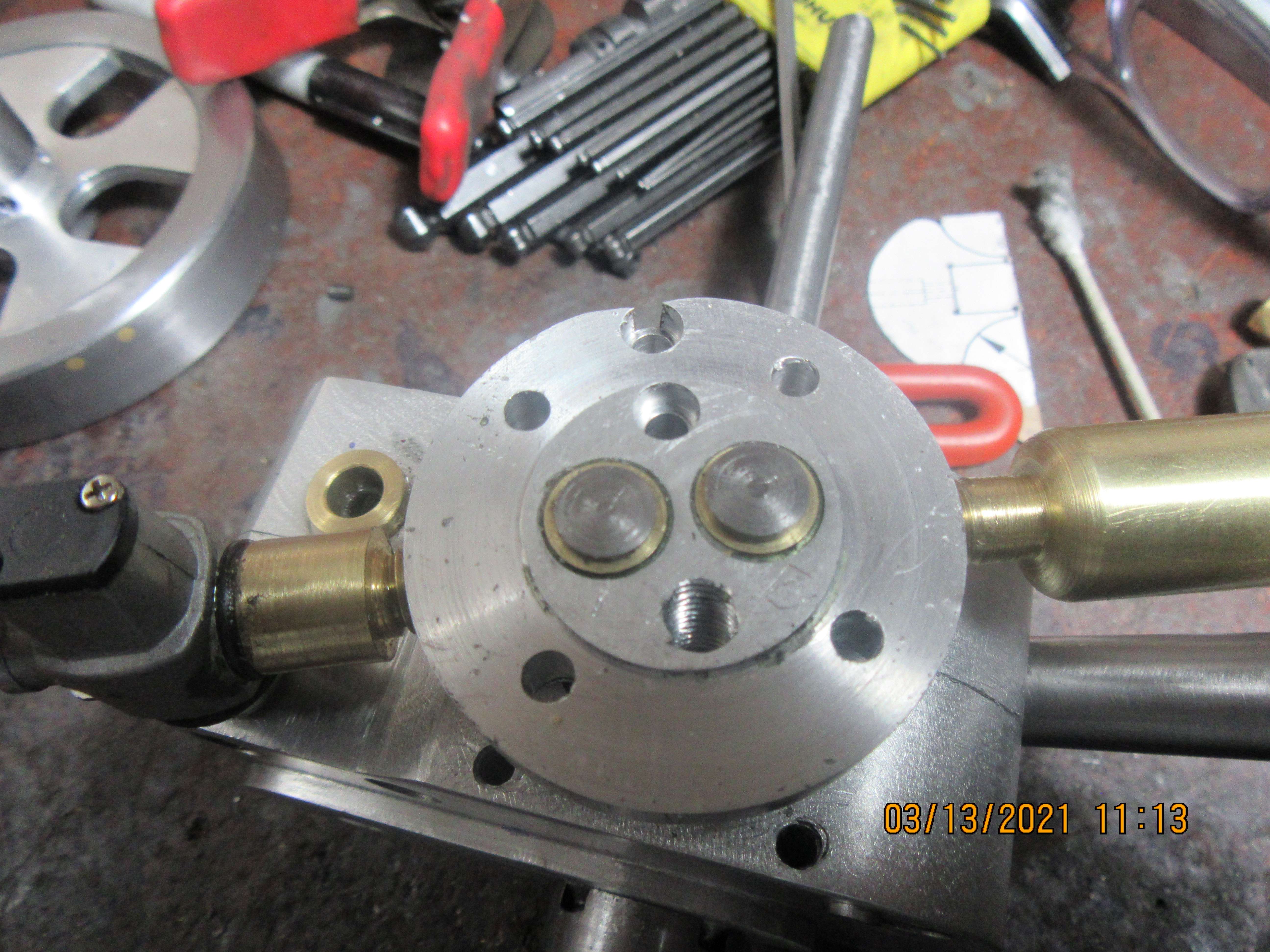

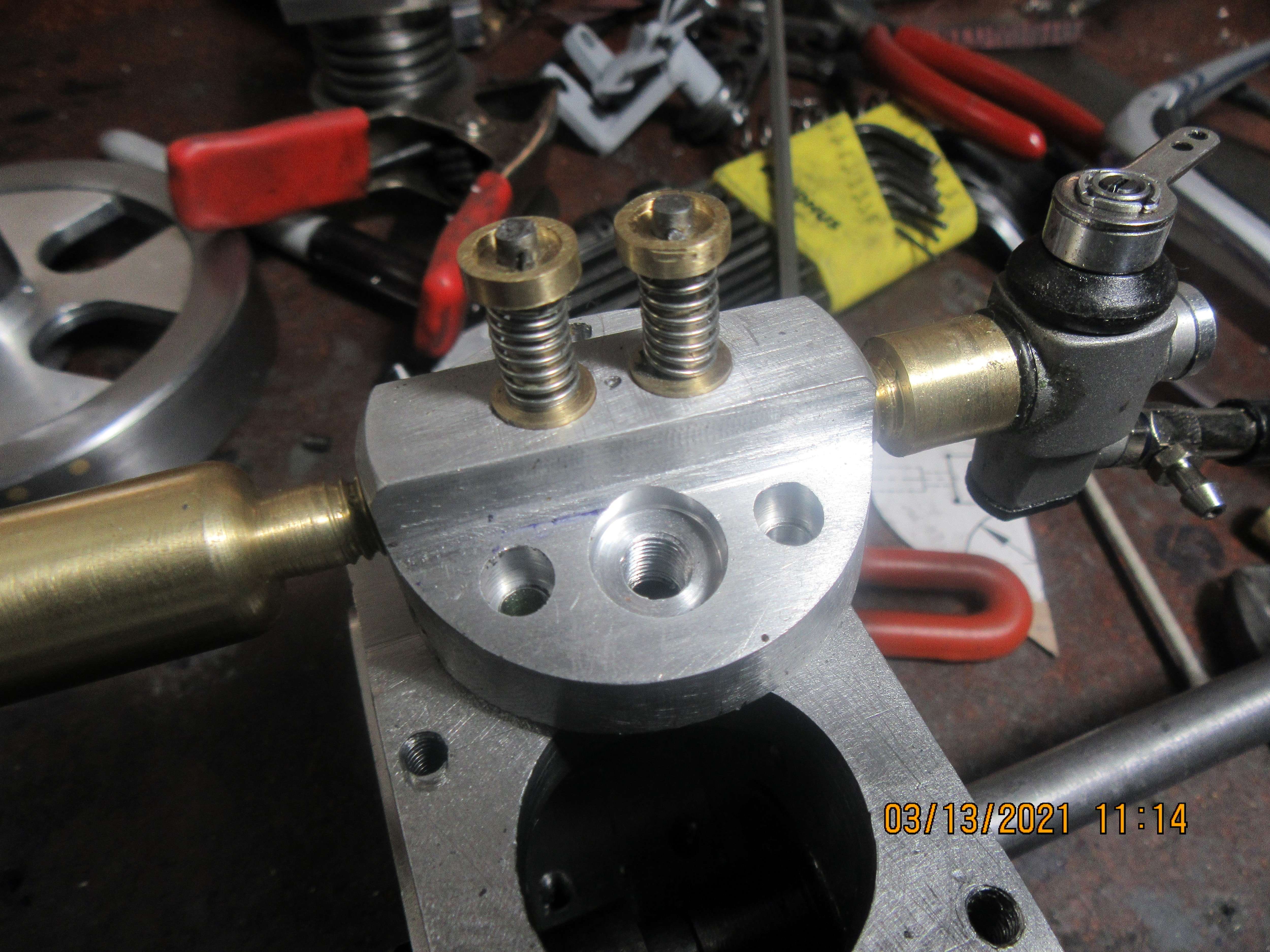

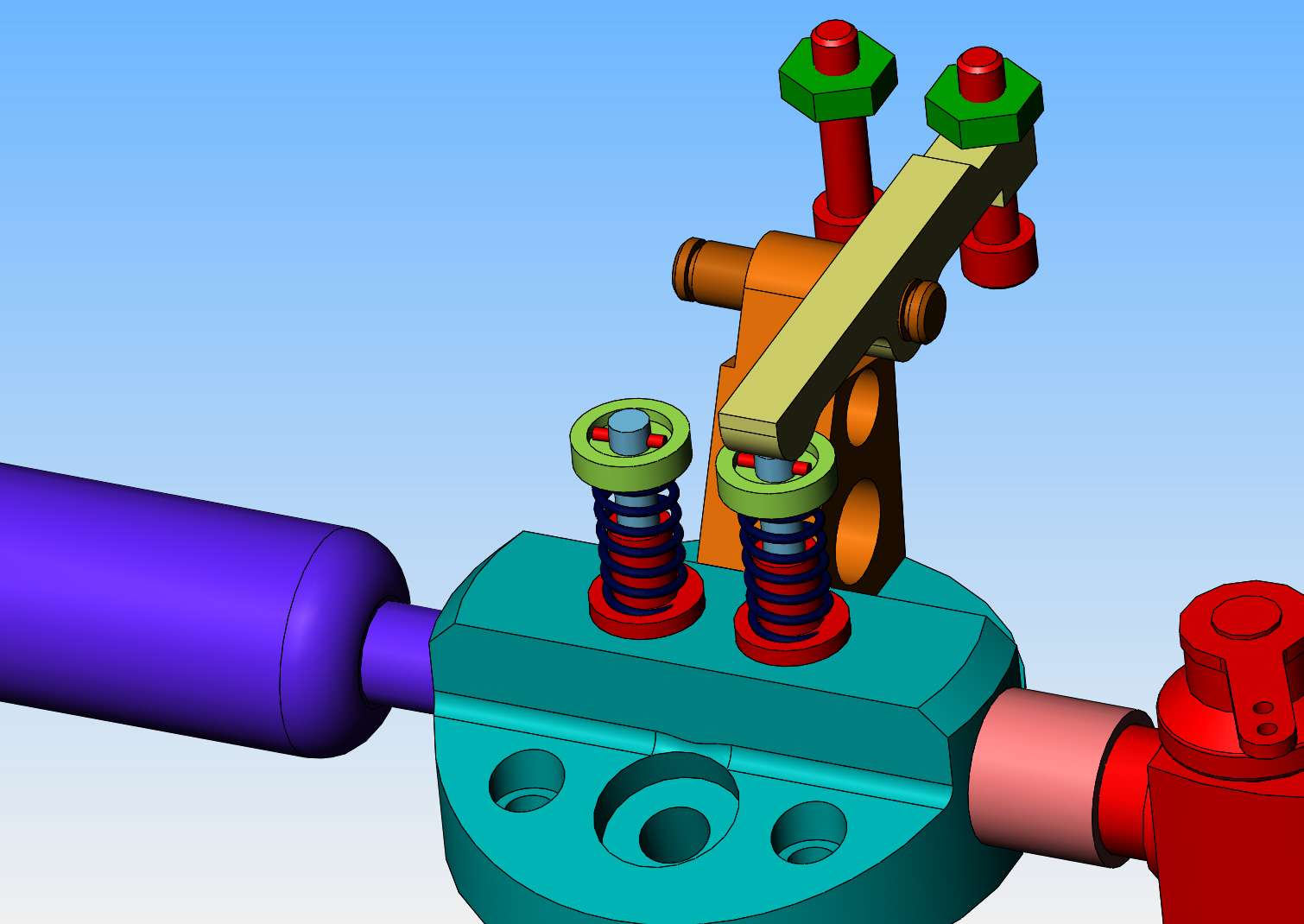

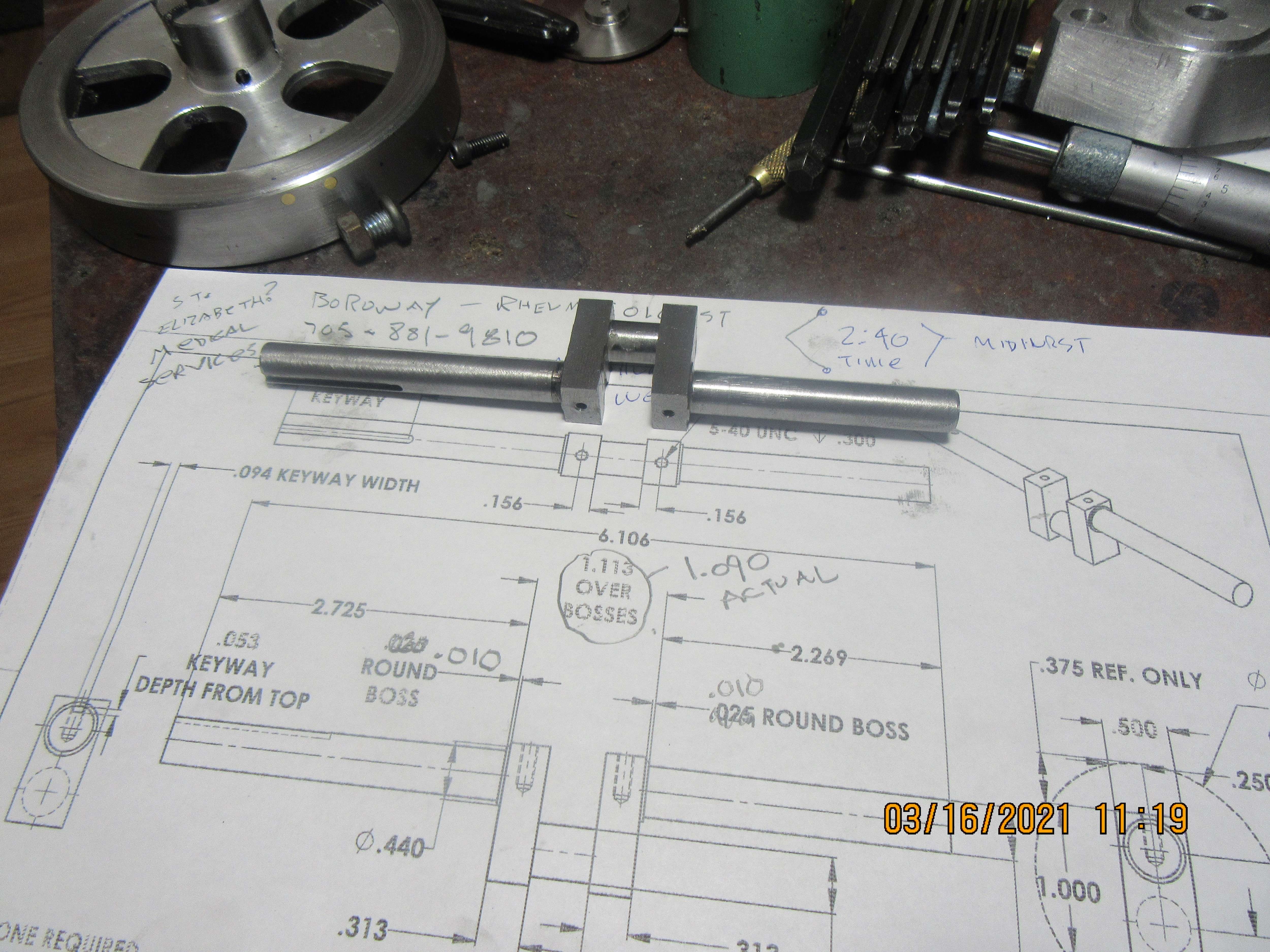

Here we have both valves, valve springs, and spring keepers assembled in the cylinder head. The valves were lapped into the seats first with #320 grit lapping paste, then 400 grit lapping paste, and finally with 600 grit lapping paste. After lapping the valves had the "handle portion" above the taper trimmed off and about .025" left at 5/16" diameter before the taper begins.