Thank you John. Painting is a relatively new thing for me, and I'm not really sure about how I feel about it. It does make the models more visually attractive. Richard--I always thought acupuncture was Chinese bull$hit, but a few years ago I had one hip and top part of my leg went all numb. I tried all of the modern medical treatments and therapies to fix it, and none of them worked. One of my therapists suggested acupuncture, and since nothing else had worked I said go ahead and do it . Amazingly, after only a few acupuncture sessions, the feeling was restored in my hip and leg, as good as new. I'm not nearly so suspicious of acupuncture now.---Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1" Bore x 1" Stroke Vertical i.c. Engine

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Richard Hed

Well-Known Member

- Joined

- Nov 23, 2018

- Messages

- 2,378

- Reaction score

- 613

I never considered it bull, but I definitely wasn't sure what it was or how it workt, but I have had similar miraculous results. Does not work for cancer, I thimk it will not work for arthritis, but not sure.Thank you John. Painting is a relatively new thing for me, and I'm not really sure about how I feel about it. It does make the models more visually attractive. Richard--I always thought acupuncture was Chinese bull$hit, but a few years ago I had one hip and top part of my leg went all numb. I tried all of the modern medical treatments and therapies to fix it, and none of them worked. One of my therapists suggested acupuncture, and since nothing else had worked I said go ahead and do it . Amazingly, after only a few acupuncture sessions, the feeling was restored in my hip and leg, as good as new. I'm not nearly so suspicious of acupuncture now.---Brian

I wish you all the best Brian. I had carpal tunnel to the point I could not use my right hand and have trained myself to use a left-hand mouse. With all of the computer work you have been doing on your latest master piece, I am not surprised you are having wrist issues. It takes a concerted effort to relax your hand when using the mouse. A wrist brace has really helped me, and having a good pad under my wrist for both the keyboard and the mouse helps a bit as well.

I like your choice of fire red and look forward to seeing how it looks on the engine. It seems there are not many of us IC builders left these days and we need to encourage and support each other. Brian, know I am actively watching your build and have always been a fan. Again, wishing you the best.

I like your choice of fire red and look forward to seeing how it looks on the engine. It seems there are not many of us IC builders left these days and we need to encourage and support each other. Brian, know I am actively watching your build and have always been a fan. Again, wishing you the best.

Thank you Eccentric---That was a very kind post. Whatever is wrong with my hands, I think it is more related to all of the machining I have been doing. 3d work on the computer has never bothered me. I have two wrist braces on, and am waiting for a blood test tomorrow. Whatever it is, it's damned painful and uncomfortable.

Richard Hed

Well-Known Member

- Joined

- Nov 23, 2018

- Messages

- 2,378

- Reaction score

- 613

What does your butcher--I mean, doctor say about glucosamine? It helps me a little, maybe not enough but a little. I workt last summer in the harvest in which when I was driving the harvester, I was always gripping two objects: with left hand, the steering wheel; with right hand, the joy-stick. I did this for five months which meant that my finger joints were squeezed together for too many hours in the day. This causes the joint material, cartilege, to be compressed like a sponge for too long. This will end up in one of the forms of arthritis eventually. Was your work in machining like that? The thing is, if you are working for yourself, you can take a break when ever yuou like. Working for someone else, you can't.Thank you Eccentric---That was a very kind post. Whatever is wrong with my hands, I think it is more related to all of the machining I have been doing. 3d work on the computer has never bothered me. I have two wrist braces on, and am waiting for a blood test tomorrow. Whatever it is, it's damned painful and uncomfortable.

dnalot

Project of the Month Winner !!!

I have two wrist braces on, and am waiting for a blood test tomorrow. Whatever it is, it's damned painful and uncomfortable.

I share your pain. My hands, especially my thumbs are in pain 24/7. I was diagnosed with osteoarthritis and psoriatic arthritis. I am being treated with a biologic injection now. It helps some with the pain but leaves me so depleted that I can only work in the shop a couple hours a day. I guess getting old is not for wimps. Just keep your eyes on the prize and keep on trucken.

Mark T

I've has carpal tunnel syndrome before, but not this bad. Last time I had it was about 10 years or more ago, and I don't remember a lot about it. I know that they offered me surgery to correct it and I said no, and after a few months it went away by itself. I want to be able to finish this engine.

I've sat around the house with wrist braces on and done nothing for three or four days and I'm going crazy!!! I really wasn't happy with the cooling fan I had made from an old pitted piece of 0.050" thick plate. The process worked fine, but the pitted material looked awful. This afternoon I snooped around in by boxes of cut-offs, and found a 2" diameter piece of 316 stainless steel, just long enough to grip in my chuck jaws and turn to 1 3/4" outer diameter. I had enough material to make a fan blade 0.060" thick with a 1/8" thick x 1/2" diameter hub on it. I will investigate cutting the slots with a cut-off saw to give the sides of the blades a little smoother finish than a band-saw cut. Does anyone know if this material takes silver solder okay?

dnalot

Project of the Month Winner !!!

Yes S.S. silver solders just fine.

Mark T

Mark T

Last edited:

Hello Brian,

Don't Know if you know this but..

Soak your wrist pain in a solution of warm water and Epsom salt for 15 minutes. The water should be as high temperatures can handle. You will have to absorb the pulse in a solution of cold water for 30 seconds. There are MANY other things you can do from your own home to cure your carpal tunnel problems. The Epsom salts turns into magnesium and additionally buy a high quality dose of Magnesium capsules and take a maximum dose of this daily for all aches and pains.

!n 1991 I was going to a Chiro 3 time a week for 6 months and not one day was I without back pain. after getting onto Magnesium today at 86 I have no aches or pain and walk 5K per day 5 days per week.

Hope this helps Brian also cut out as much sugar as you can as it is acidic. Acid causes pain! Stay well. John

Don't Know if you know this but..

Soak your wrist pain in a solution of warm water and Epsom salt for 15 minutes. The water should be as high temperatures can handle. You will have to absorb the pulse in a solution of cold water for 30 seconds. There are MANY other things you can do from your own home to cure your carpal tunnel problems. The Epsom salts turns into magnesium and additionally buy a high quality dose of Magnesium capsules and take a maximum dose of this daily for all aches and pains.

!n 1991 I was going to a Chiro 3 time a week for 6 months and not one day was I without back pain. after getting onto Magnesium today at 86 I have no aches or pain and walk 5K per day 5 days per week.

Hope this helps Brian also cut out as much sugar as you can as it is acidic. Acid causes pain! Stay well. John

Hi Brian,

I knew a guy who had been crippled with arthuritis. (25 years ago). He went on an acid free diet: No wine, only beer and gin (he had a huge wine cellar - a connoisseur.). No tea of COFFEE. Mineral water only, Not spring water. Seriously, everything he had ever eaten was studied and he hit the "no acid" mark - after which he recovered in a month to get back to work! He reckoned it was almost miraculous. But depends on your problem if you can starve Arthur of acid and get better, or if another problem. I have mild gout. I've been taking Turmeric all winter for the Arthur in my finger joints (damaged by cold from motorcycling all winter, and the gout). It seems to work as although the joints are a bit swollen, mostly they don't hurt. Or at least most days. In October it was 6 days pain, 1 day relief, now 1 day pain per week.

Hope you find a solution to your problem soon. Having had the carpal tunnel thing from the early years of using a computer mouse I know it took me 6 weeks before I was "good to go", and loose the wrist splint.

Cheers mate!

K2

I knew a guy who had been crippled with arthuritis. (25 years ago). He went on an acid free diet: No wine, only beer and gin (he had a huge wine cellar - a connoisseur.). No tea of COFFEE. Mineral water only, Not spring water. Seriously, everything he had ever eaten was studied and he hit the "no acid" mark - after which he recovered in a month to get back to work! He reckoned it was almost miraculous. But depends on your problem if you can starve Arthur of acid and get better, or if another problem. I have mild gout. I've been taking Turmeric all winter for the Arthur in my finger joints (damaged by cold from motorcycling all winter, and the gout). It seems to work as although the joints are a bit swollen, mostly they don't hurt. Or at least most days. In October it was 6 days pain, 1 day relief, now 1 day pain per week.

Hope you find a solution to your problem soon. Having had the carpal tunnel thing from the early years of using a computer mouse I know it took me 6 weeks before I was "good to go", and loose the wrist splint.

Cheers mate!

K2

For silver soldering Stainless (nickel based alloys) you need a special flux, or suffer poor "wetting" by the fluidus. (A surface tension problem). It also copes with the higher temperature solders you are likely to use. I found Stainless 304 stays on a copper boiler didn't seal until I used the flux for stainless... "Seemed" to be held strongly, but were threaded into the copper anyway, however they all leaked at the solder to S/S interface - not good for a boiler! Cleaning the flux off needs a hard chisel, it isn't water soluble like the regular flux for copper work.

Could a friction weld work for you? - The fan is very low power! - e.g. boss with flange held in chuck for rotation: fan located on boss, and pressed onto surface with a sleeve (Axial pressure from tail-stock) NOT rotating. Run, press gently, till hot. When hot stop lathe apply pressure simultaneously and the fan may weld onto the flange of the boss...

Enjoy!

K2.

Could a friction weld work for you? - The fan is very low power! - e.g. boss with flange held in chuck for rotation: fan located on boss, and pressed onto surface with a sleeve (Axial pressure from tail-stock) NOT rotating. Run, press gently, till hot. When hot stop lathe apply pressure simultaneously and the fan may weld onto the flange of the boss...

Enjoy!

K2.

My greatest apologies to all who were following this thread. I was hoping to be finished by the end of February but my 74 year old body is causing me some distress right now, so I have to slow down a bit. Between carpal tunnel syndrome in my wrists and arthritis in my knees, I have been told by the doctor to back off a bit. There is the vague spectre of knee replacement surgery lurking in the background, but I doubt it will actually come to that. I will continue updating this thread (everything is completed except for the crankshaft and counterweights and spring keepers for the valves). Hang in there folks, this will get finished, just not as quickly as I had hoped.---Brian

Brian,

Don't worry about the hobby, get yourself as fit as you can first, every thing else will follow

Cheers

Andrew

Don't worry about the hobby, get yourself as fit as you can first, every thing else will follow

Cheers

Andrew

Your health is the most important thing now.

Stay well

Ray

Stay well

Ray

Look after number 1 - then she'll be fit enough to look after you - or make the end "painless" while she inherits the Insurance!

Stick in there Brian, Reading doesn't need that much joint movement. STAY WARM - the cold in the workshop affects me most in this season.

We'll all chat again when you are improved (unless She gets you first!).

K2

Stick in there Brian, Reading doesn't need that much joint movement. STAY WARM - the cold in the workshop affects me most in this season.

We'll all chat again when you are improved (unless She gets you first!).

K2

jamesmattioli

Active Member

Spero molta salute per te rimettiti in forma, il motore lo finirai in futuro. CiaoMy greatest apologies to all who were following this thread. I was hoping to be finished by the end of February but my 74 year old body is causing me some distress right now, so I have to slow down a bit. Between carpal tunnel syndrome in my wrists and arthritis in my knees, I have been told by the doctor to back off a bit. There is the vague spectre of knee replacement surgery lurking in the background, but I doubt it will actually come to that. I will continue updating this thread (everything is completed except for the crankshaft and counterweights and spring keepers for the valves). Hang in there folks, this will get finished, just not as quickly as I had hoped.---Brian

Okay!! I'm still fighting carpal tunnel in my hands, but today boredom got the better of me, so I've made a bit more progress. In a perfect world, I would machine all of my parts exactly to the drawings I make.---In the real world, I come close, but there are a few areas where this gets very critical. One of these places is the width between the ball bearings in the crankcase. There is very little clearance between the inside of the ball bearings and the crankshaft, which is the part I'm making next. If there is too much clearance, then there will be issues of crankshaft endplay. The engine will still run okay, but there will be mysterious clanks and bangs issuing from the crankcase as the crankshaft revolves and slides back and forth between the bearings. If there isn't enough clearance, then the crankshaft won't revolve when the two halves of the crankcase are bolted tightly together. I don't have a tool that will reach down thru the top of the crankcase to measure the clearance between the bearings. My answer to this is to machine a couple of "sleeves" from 1/2" diameter material. One is slid over the end of a piece of 3/8" shafting and Loctited in place. After the Loctite has set up, the shaft is slid thru the bearing on one side of the crankcase and the sleeve is butted up against the inside of the ball bearing. The other sleeve is then slid over the other end of the 3/8" shaft, slid close to it's approximate position +1/2" and a dab of Loctite put on the shaft. Then quickly, before the Loctite sets up, the other half of the crankcase (with bearing in place) is slid over the shaft until it contacts the second sleeve and pushes it ahead of the bearing until the crankcases are touching each other and bolted together. After the Loctite has set up, the two crankcase halves will be separated and I can measure the distance outside to outside of the two sleeves which are loctited to the shaft. This will tell me what the exact distance is between the two ball bearings so I can machine the crankshaft to fit with about 0.010" of overall clearance.

Clever Brian (as usual)! I may have followed basically the same approach (if I had come across this problem) as I was taught as a teenage apprentice... Insert a shaft all the way through the pair of bearings (True-size to check alignment is perfect) where there is a pair of sleeves also inserted between the bearings: The sum of these sleeves is rather less than the total width between the bearings. But each sleeve is fitted with a locking screw. So the sleeves can be slid up to touch the inside faces of the bearings, locked in place (access through the crankcase mouth) and then upon splitting the cases afterwards the dimension you want is available, - Same process, just locking screws instead of Loctite. Also used to determine shims for gear-box shaft end-float correction, etc. - or any other internal dimension. Can also be used externally, as the length of rod can be measured, the thickness of sleeves measured and the projection of rod from an external sleeve can me confirmed with a depth mic or other. The a simple computation subtracting the "external elements" from the rod length gives the overall outside dimension of the bearing pair.

Show us a pig (of a problem) and we have many ways to kill it!

It's good to be reminded of these techniques! Thanks Brian.

Show us a pig (of a problem) and we have many ways to kill it!

It's good to be reminded of these techniques! Thanks Brian.

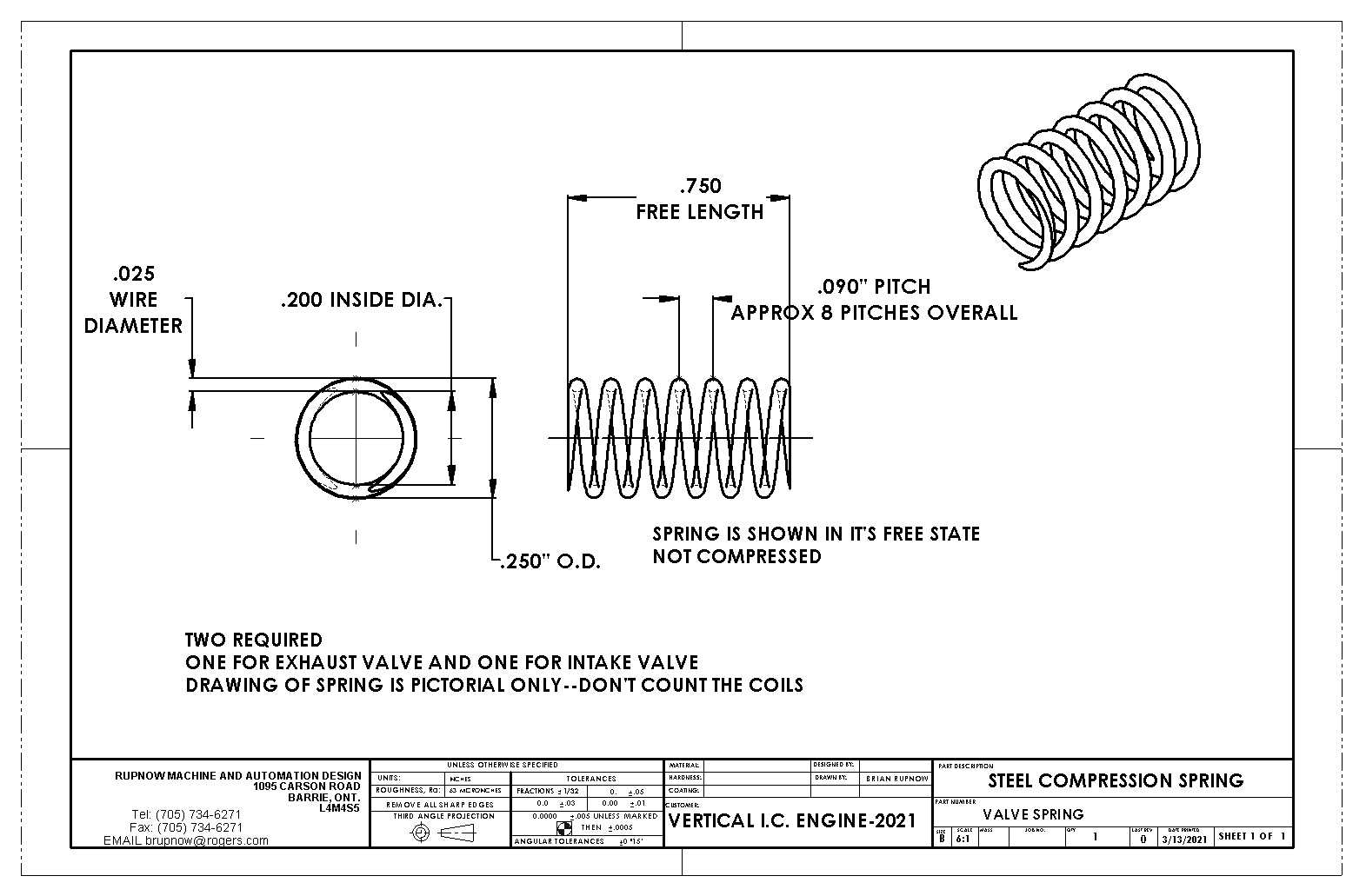

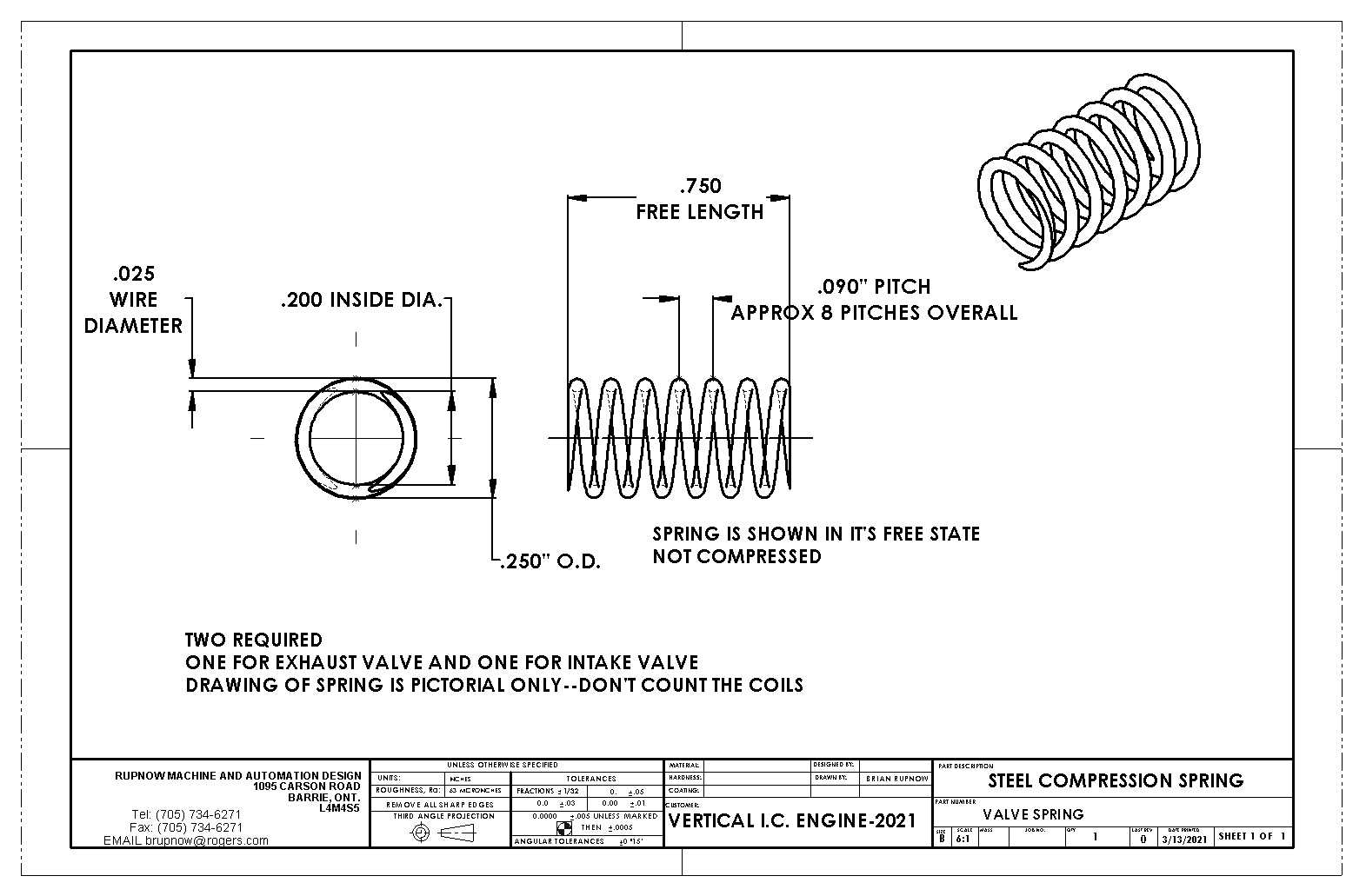

This morning bright and early, and I'm looking for things I need to do yet. I'm about to make the valve spring retainers from brass, but I needed some reference dimensions from the valve springs I am going to use first, so I thought I might as well make a drawing of the springs while I had them out being measured.

Similar threads

- Replies

- 61

- Views

- 8K

- Replies

- 148

- Views

- 19K