I don't want to beat this horse to death, but I can't resist one more post.

The problem with relying on charts has been described above: the charts are based on a table with a certain ratio in the worm gear. If your table doesn't match that ratio, the charts will be completely, utterly wrong. A secondary issue is that you may or may not have the same set of indexes as are covered in the chart.

That is why I depend on the math rather than on any charts - that, and because the math is really rather simple. Let's take a dividing head with a worm gear ratio of 60:1. None of the charts mentioned above cover this table ... but not to worry. I want my gear to have N number of teeth in one complete revolution. How many complete turns of the handle will it take to achieve one complete revolution of the gear blank? 60 - because the worm ratio is 60:1. So I need to divide those 60 turns by the N teeth that I need to cut: 60/N. This tells me exactly how much I need to turn the handle for each tooth.

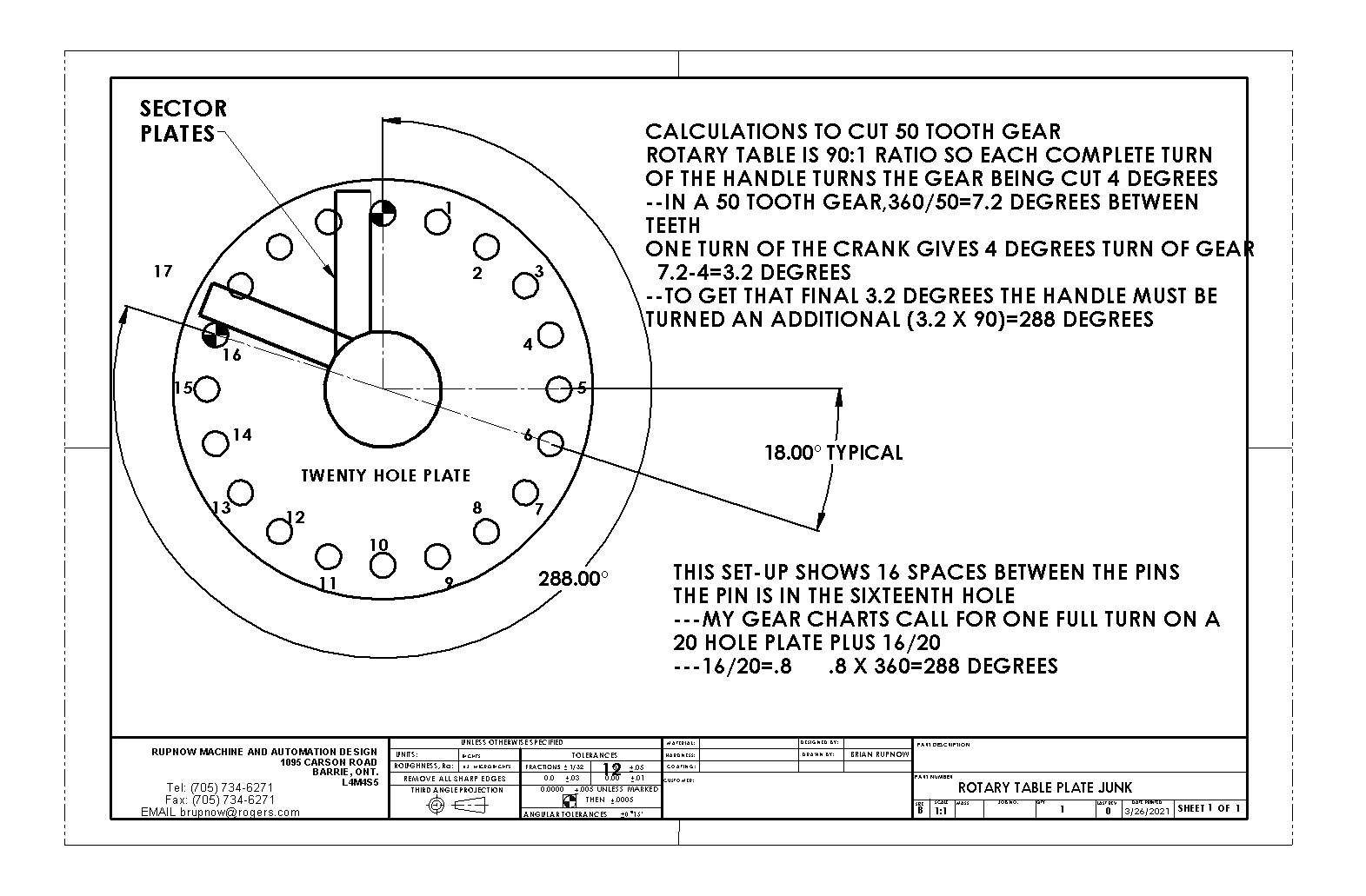

Let's say that my goal is 32 teeth. If I plug 60/32 into the calculator, I get 1.875 - but this is a place where fractions are better than decimals, so let's do it the old fashioned way; 60/32 = 1 remainder 28, or 1-28/32, which can be simplified to 1-7/8. Now I just need to find an index circle based on a multiple of 8 - 16, 24, 32 ... any of these will do. For whatever index circle I use, I will convert 7/8 to match: 14/16, 21/24, 28/32. So if I use a 24 hole index, I will need to turn the handle 1 full revolution plus 21 holes.

As discussed above, that means I need to set the sector arms up to span 22 holes - one for the current location of the index pin, and then 21 more to achieve the desired 21/24 ratio.

Okay, describing it like this above, I have to admit it may sound complicated. But really, the key is to remember that you want N teeth out of R revolutions of the handle, where R is the ratio of your dividing head.