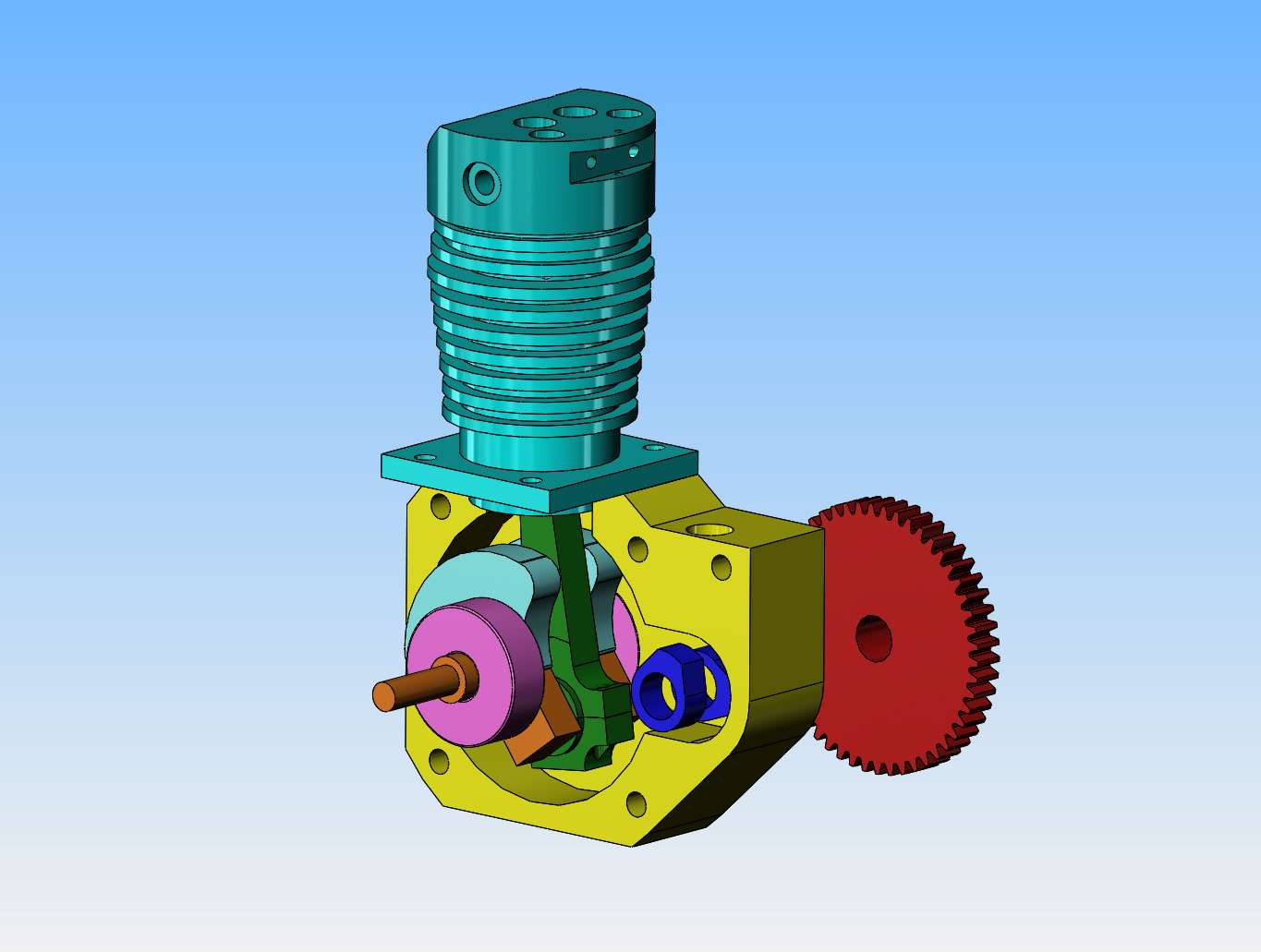

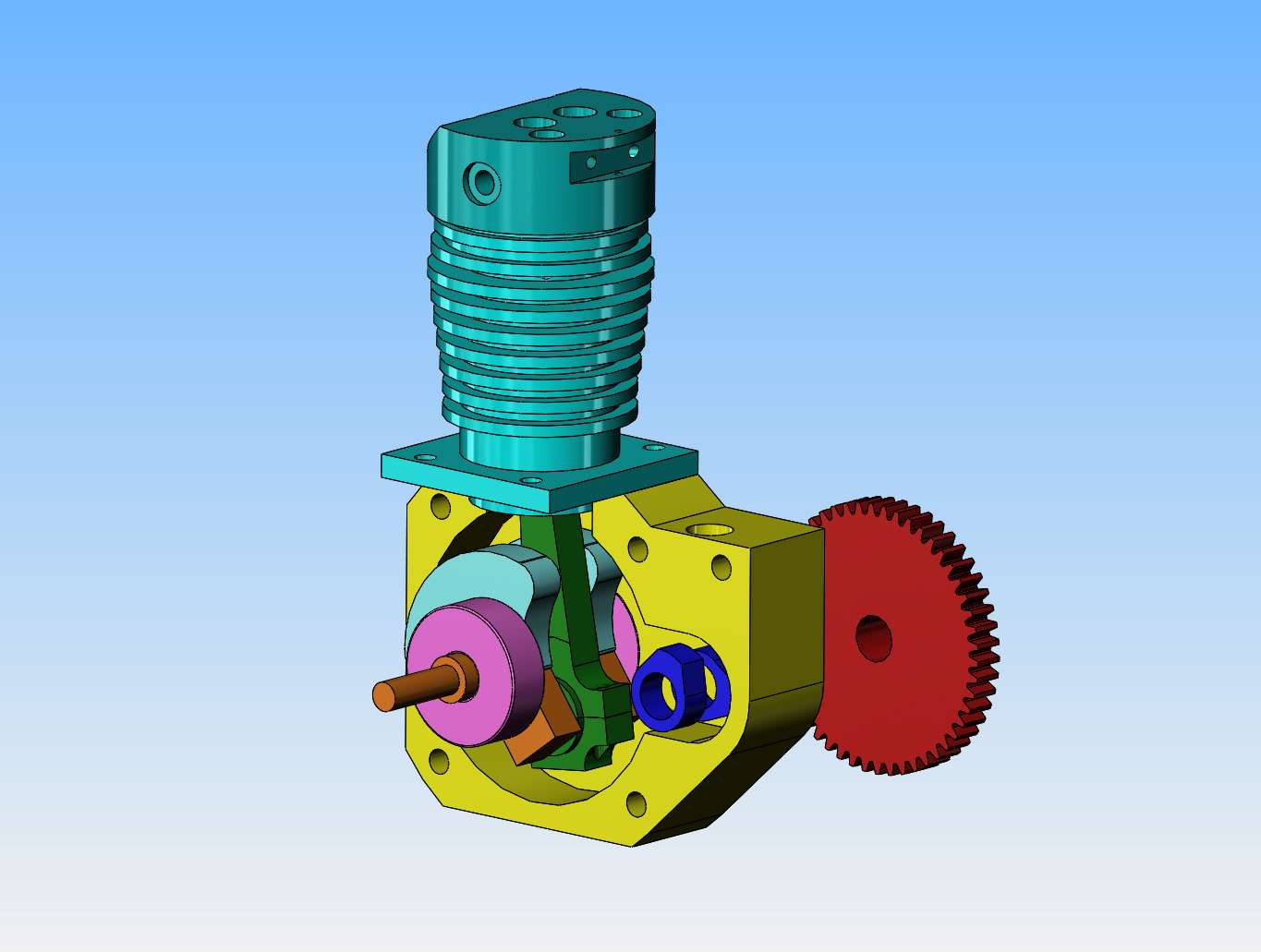

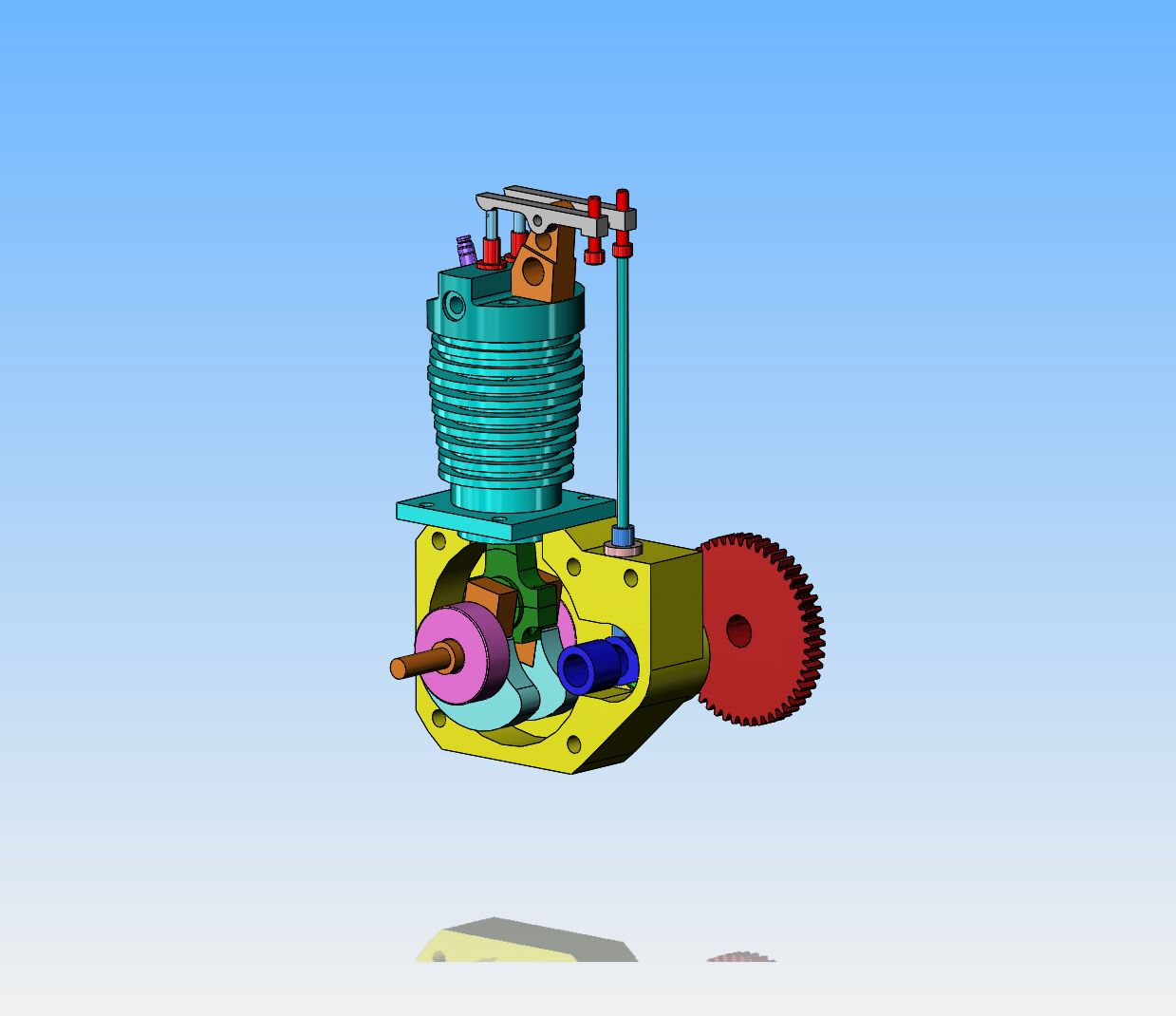

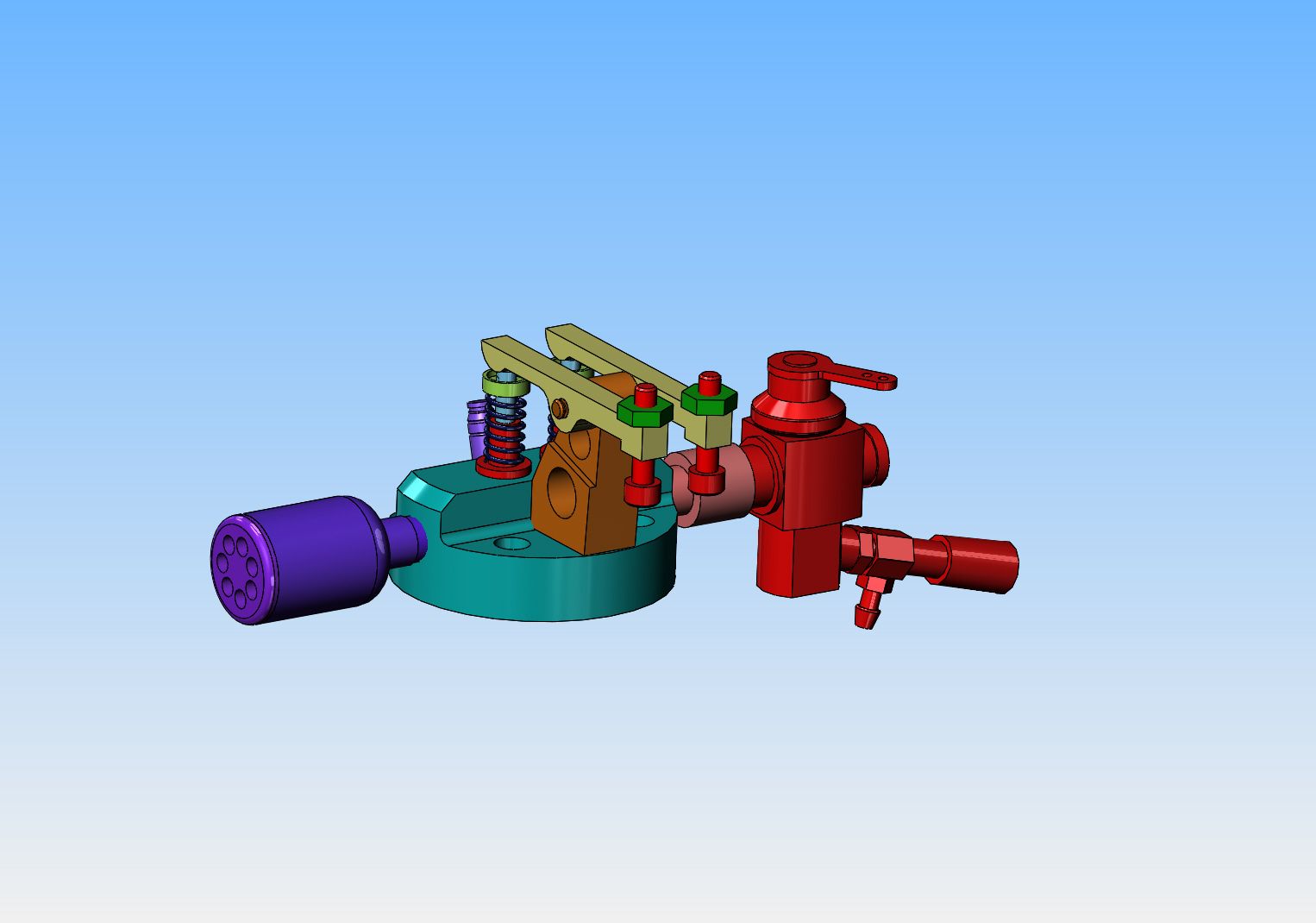

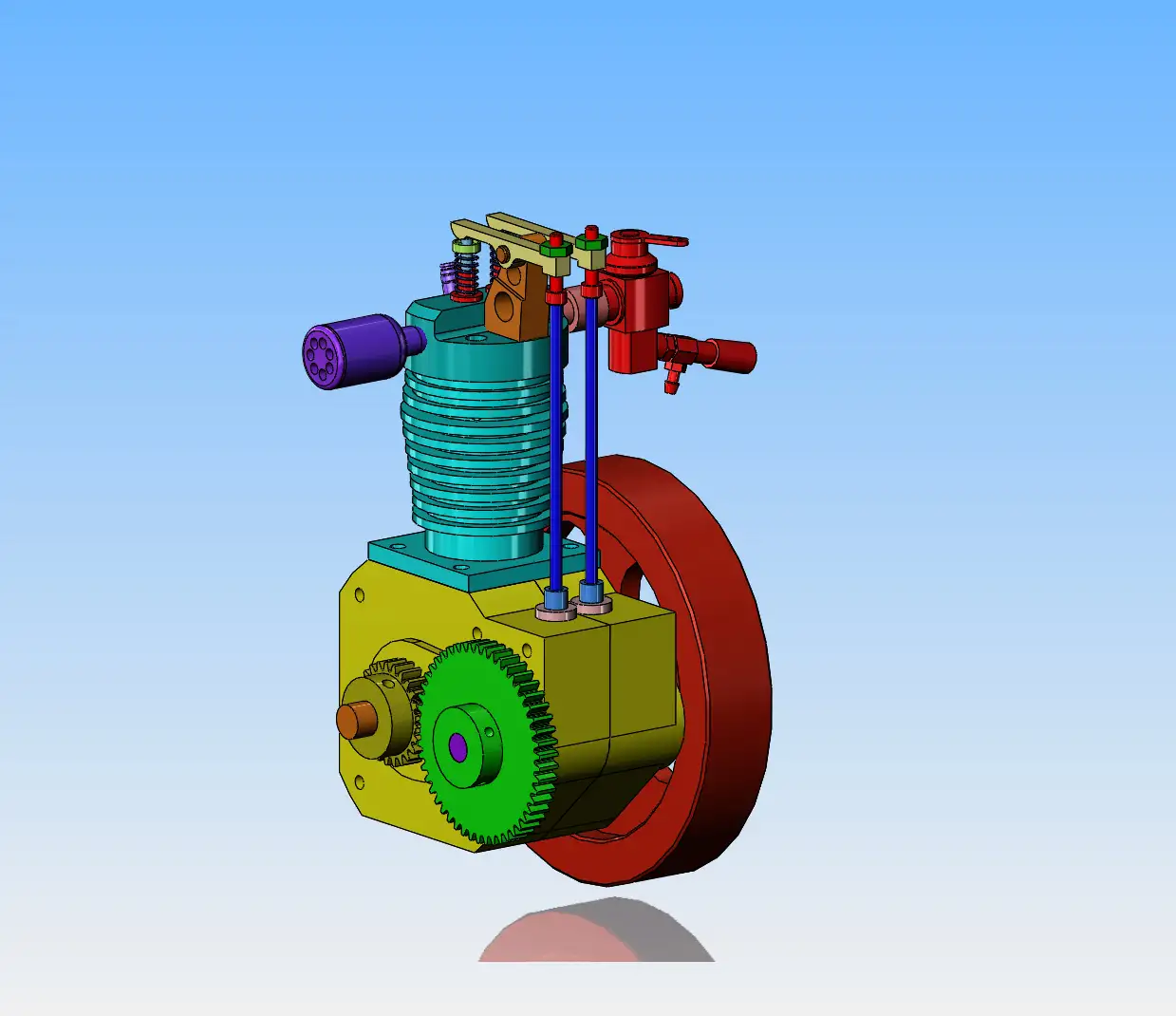

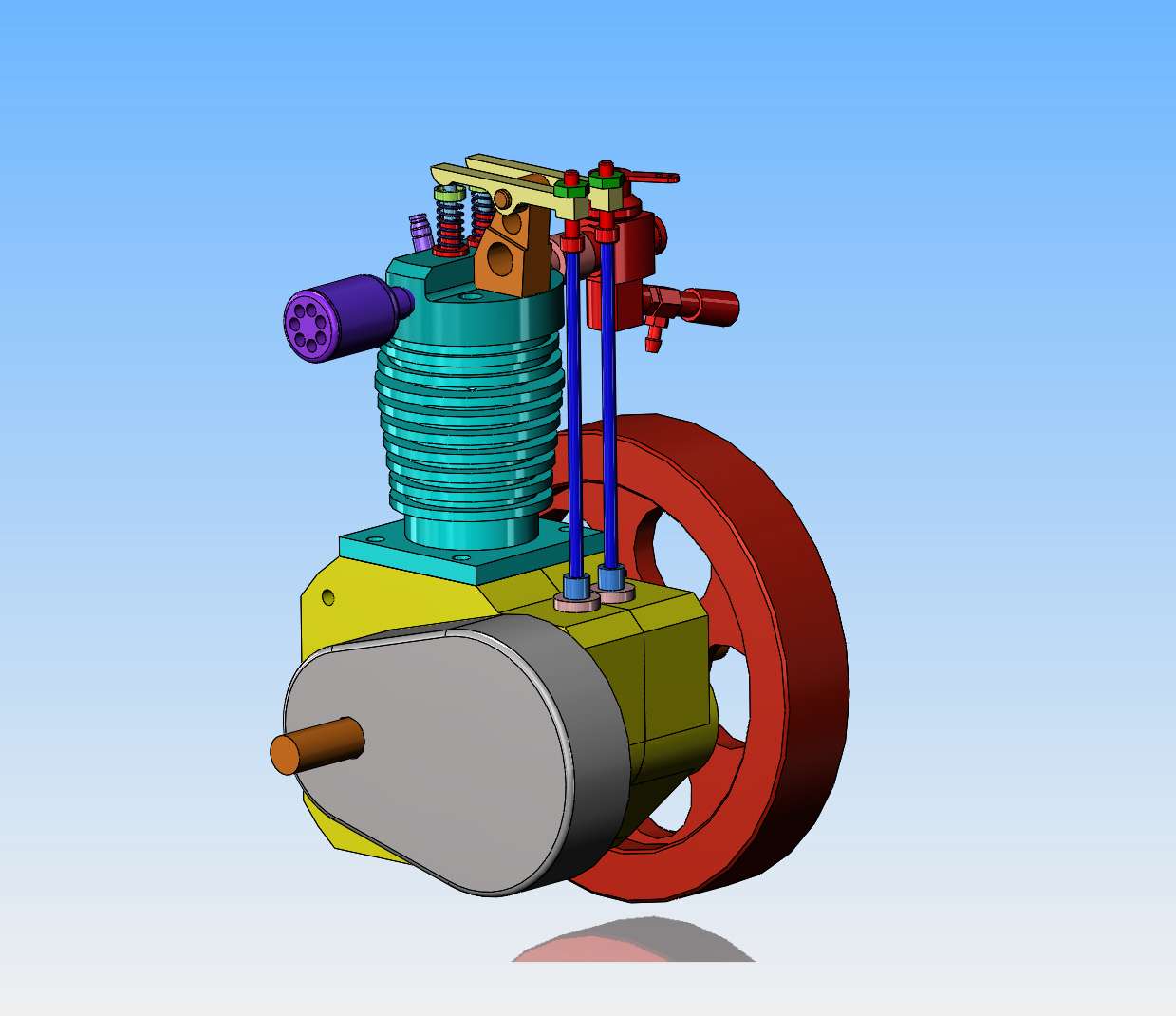

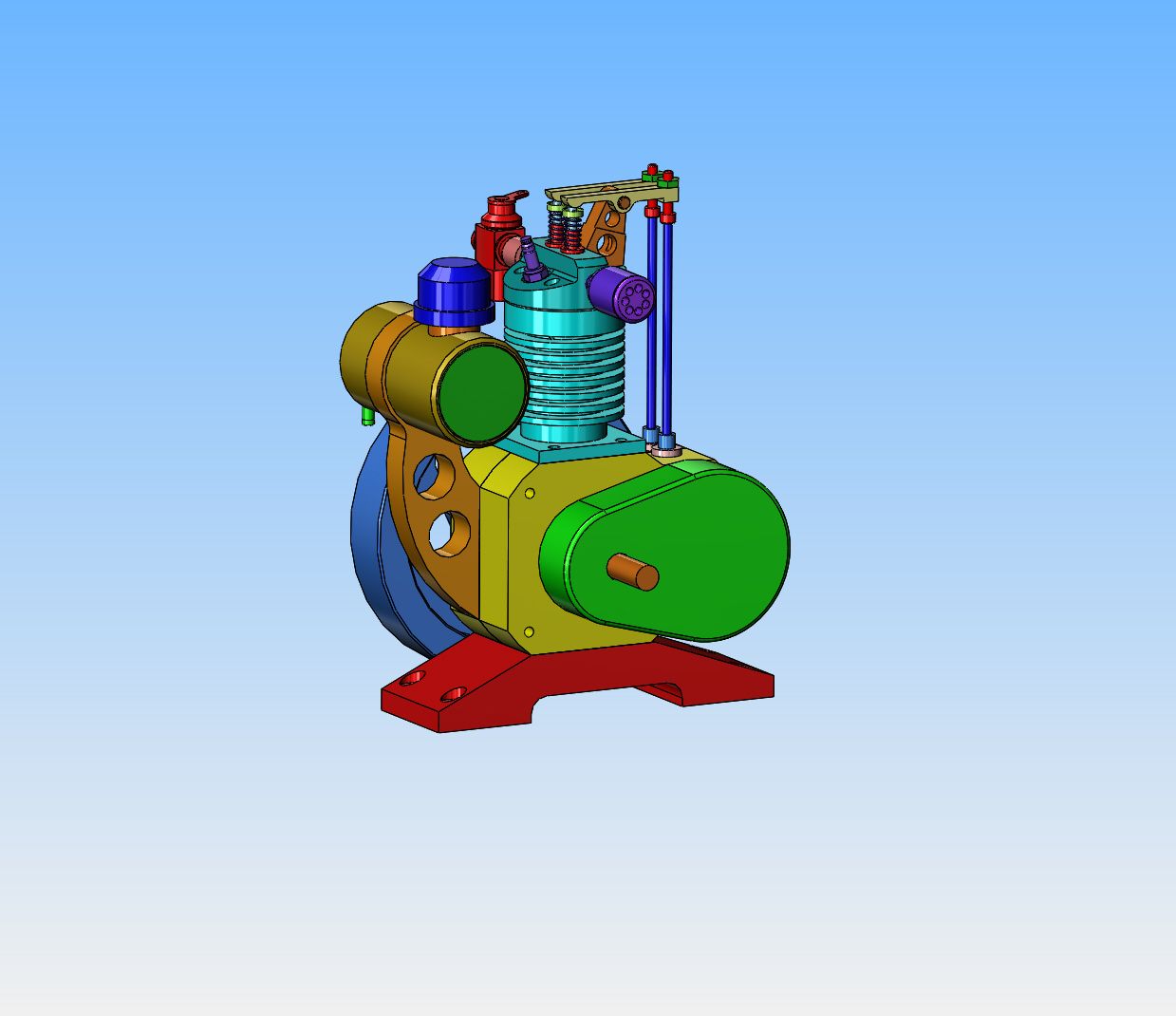

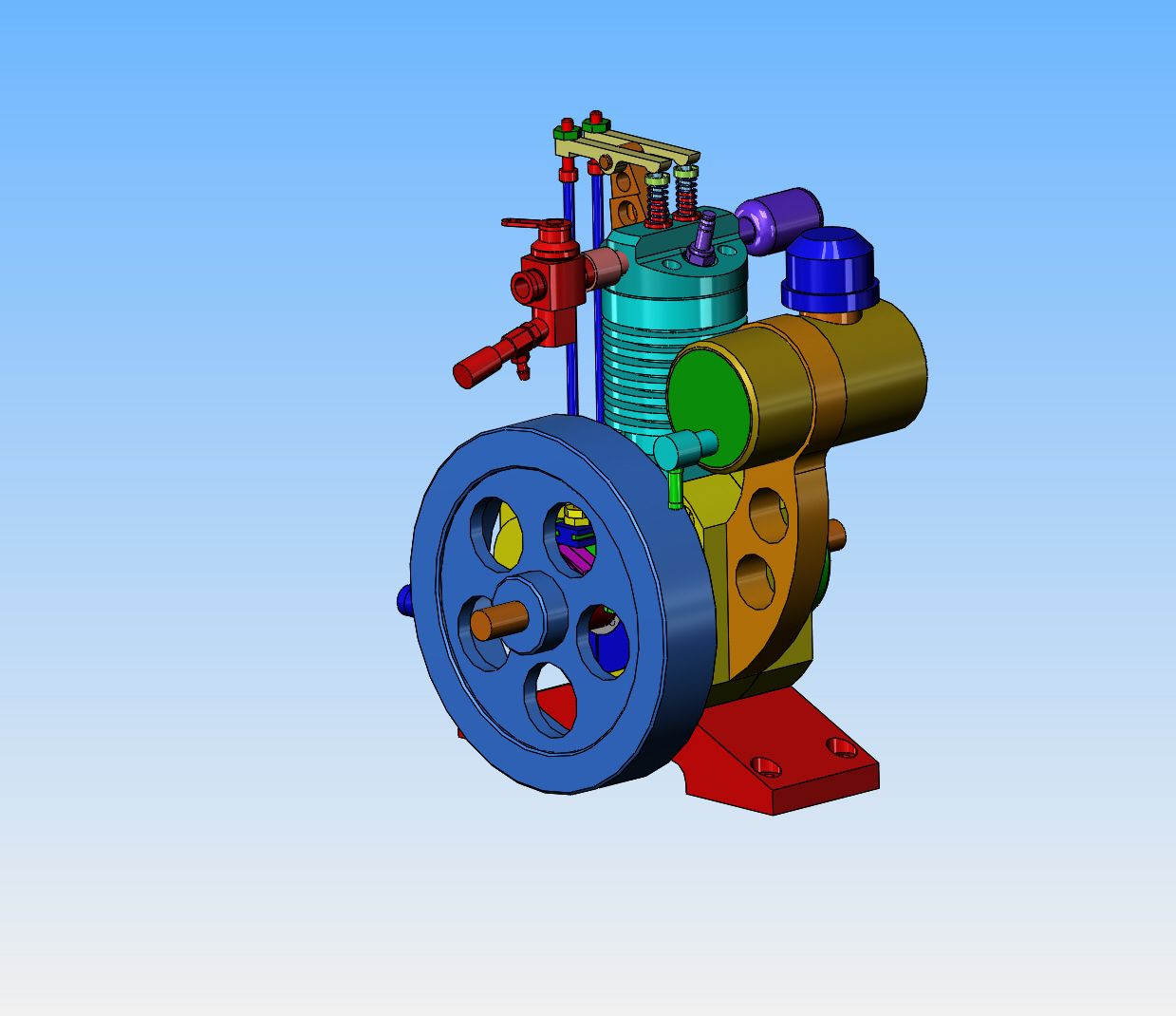

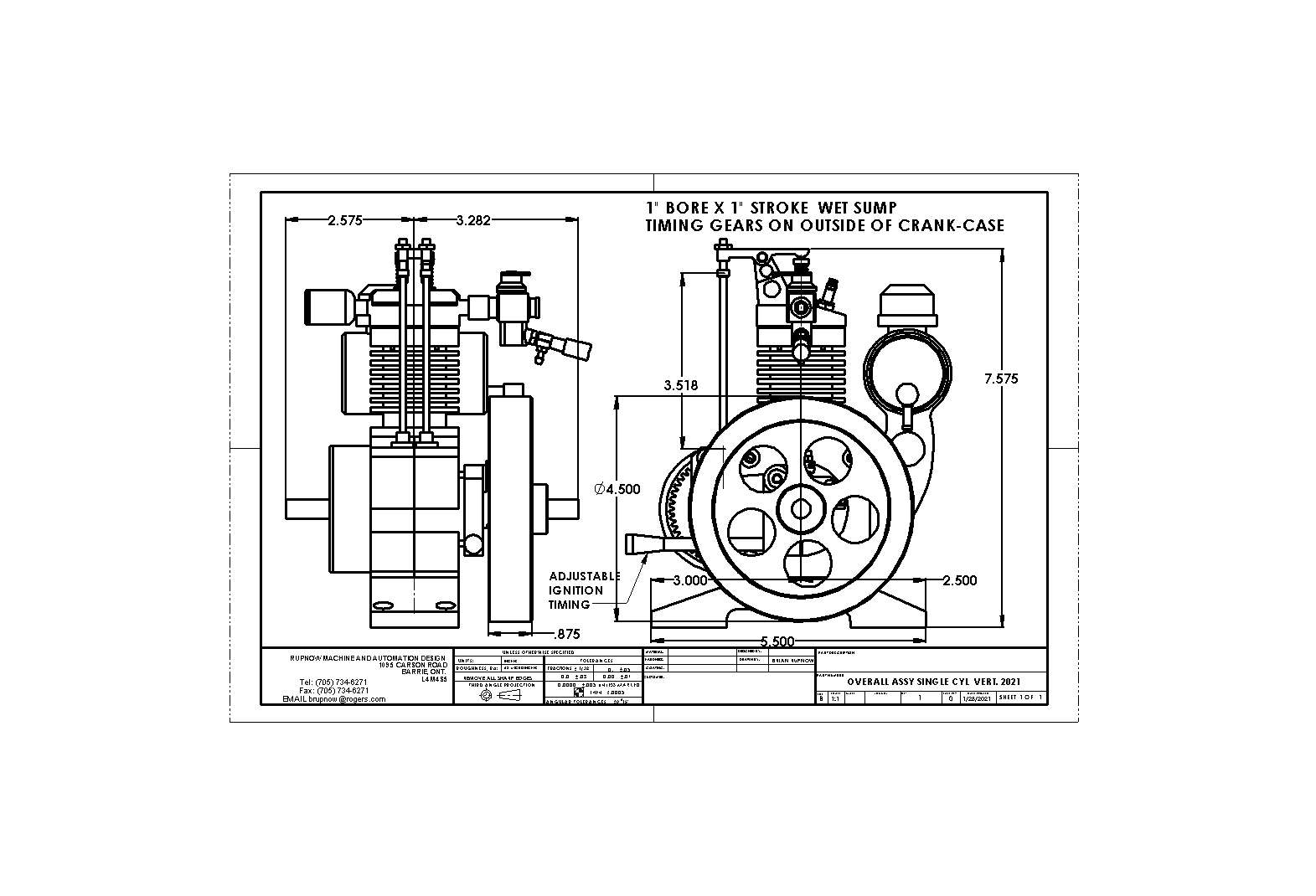

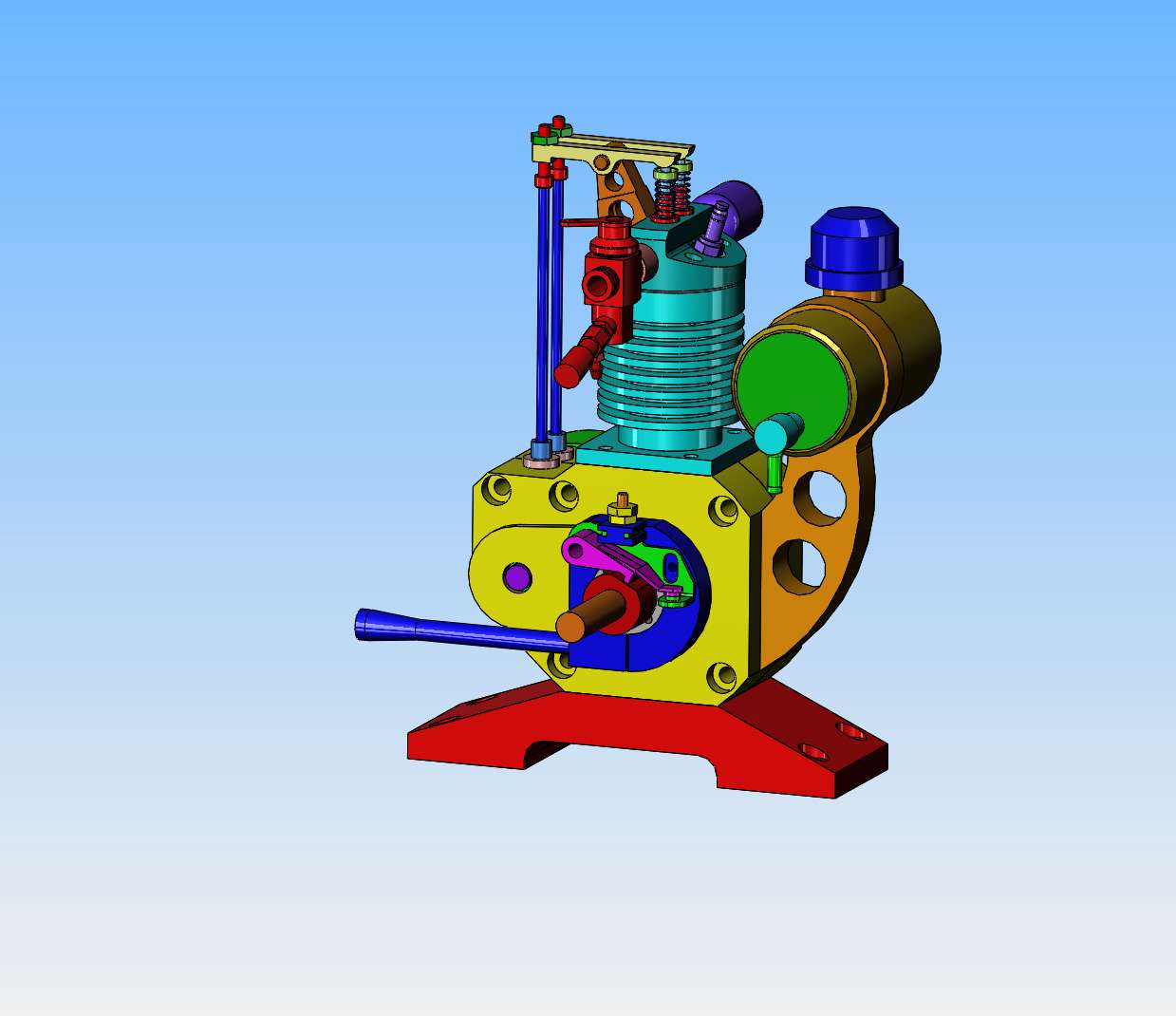

Hi Everyone---Hope your new year is going well, so far. I fell on the ice in my driveway just after Christmas and hurt my back. Between the pain from that, and my arthritis (which is exceptionally bad this year), I've had a very quiet January. Finally, today, out of boredom I sat down at my computer and started importing files from previous engines to see what would be involved in another i.c. engine. I have never built an engine before with a vertically split crank-case, so after looking at some really lovely examples on the forums, I've started putting things together on cad. I enjoy a quiet day designing, and this is what has turned up so far. Nothing really new or exciting here, but I like to see an engine coming together. I have no cnc here, just manual machinery, so that's what my engine will be based on, build-wise.---Brian