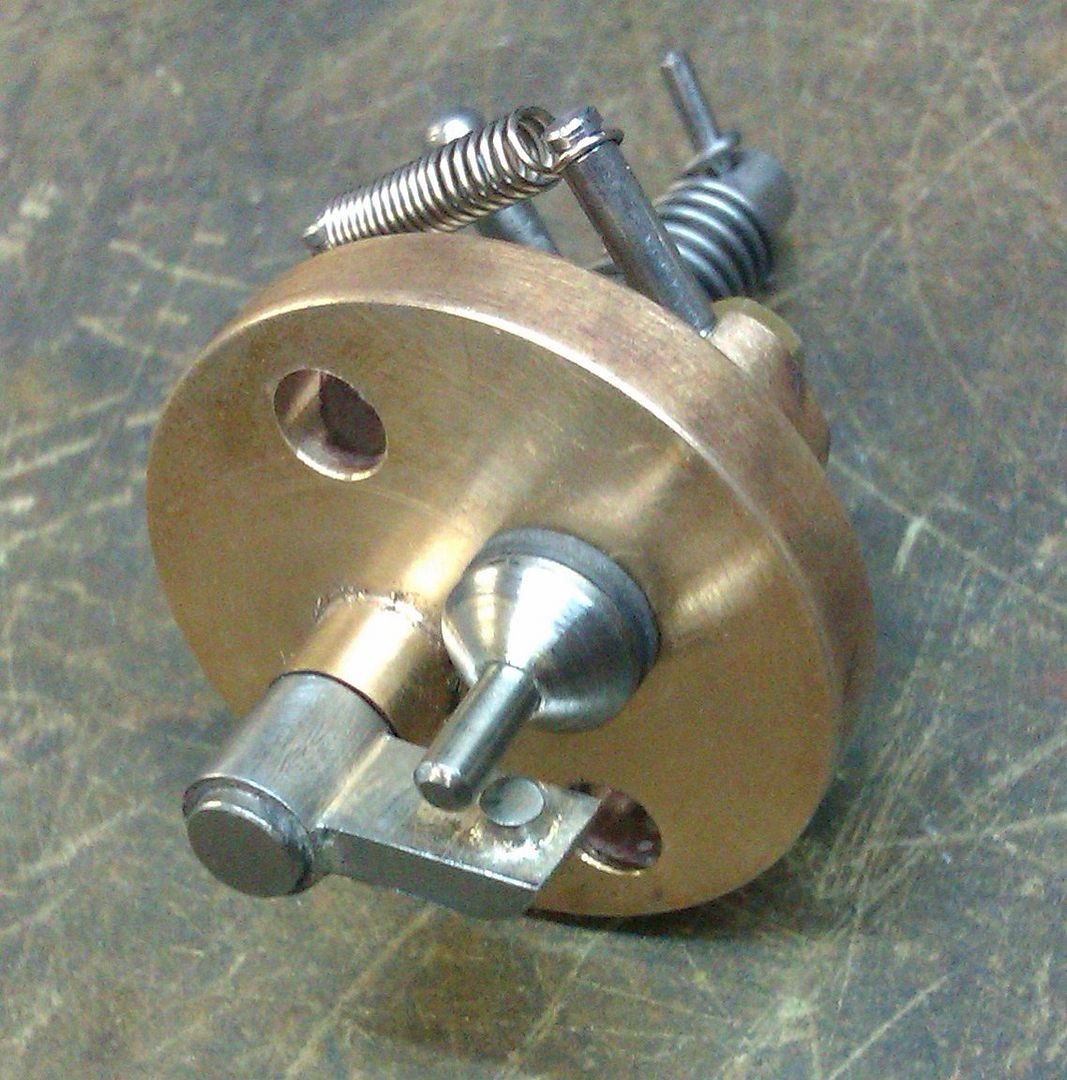

I have just finished???? a 1/6 scale Galloway hit and miss. Am trying to get it to run, but no luck so far. I suspect the problem is with the ignitor. It is a bit small and fiddly. My question is: What should the gap be in the ignitor points. I am guessing .020", or .030", but am only guessing as the plans do not address that question. I am using a multimeter to set the timing and it seems to be correct, but not knowing what is going on with the ignitor is a problem. Any help and suggestions would be greatly appreciated.

Thanks

Rick

Thanks

Rick