cwelkie

Well-Known Member

- Joined

- Dec 19, 2010

- Messages

- 170

- Reaction score

- 60

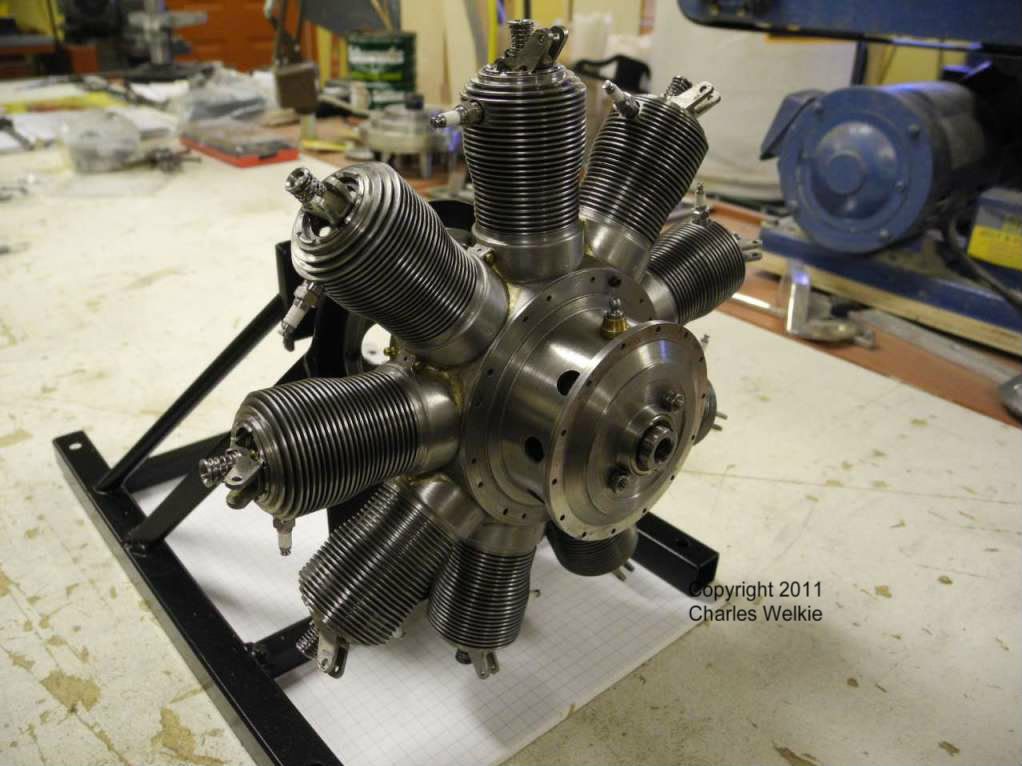

Many of you have already seen some photos of my current build - a 1/4 scale Gnome built from Stephen Wessel's excellent drawing set for a 1/3 scale version.

Just thought that you might like to see some of the recent progress ...

First - one of the spark plugs. Corian insulator with a 10-32 thread. (Sorry - I should have held the camera focus on the plug ...)

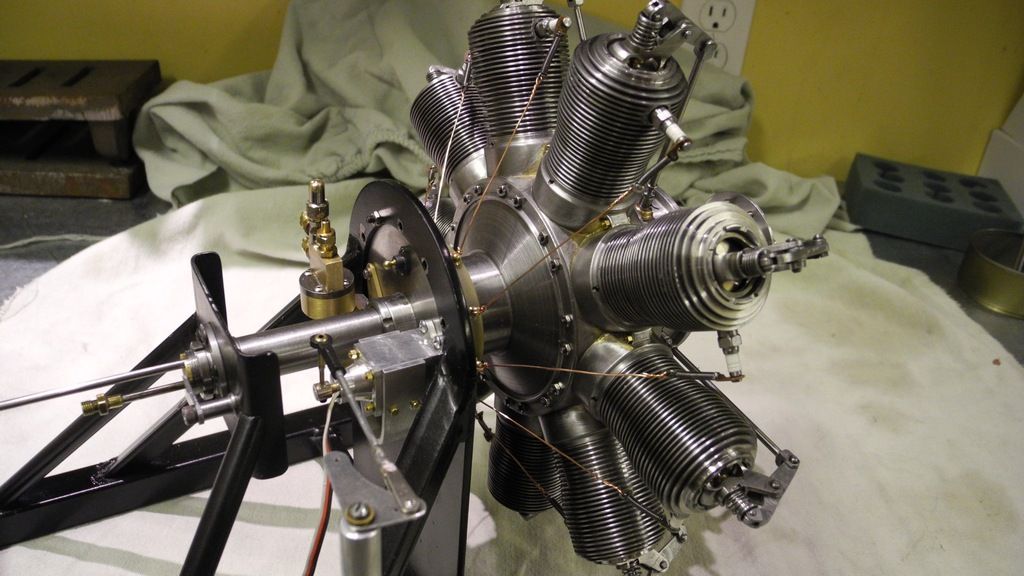

The propeller hub - still without it's splines for the "washer". (Need to make the broach before I'll be happy cutting the splines into the hub.)

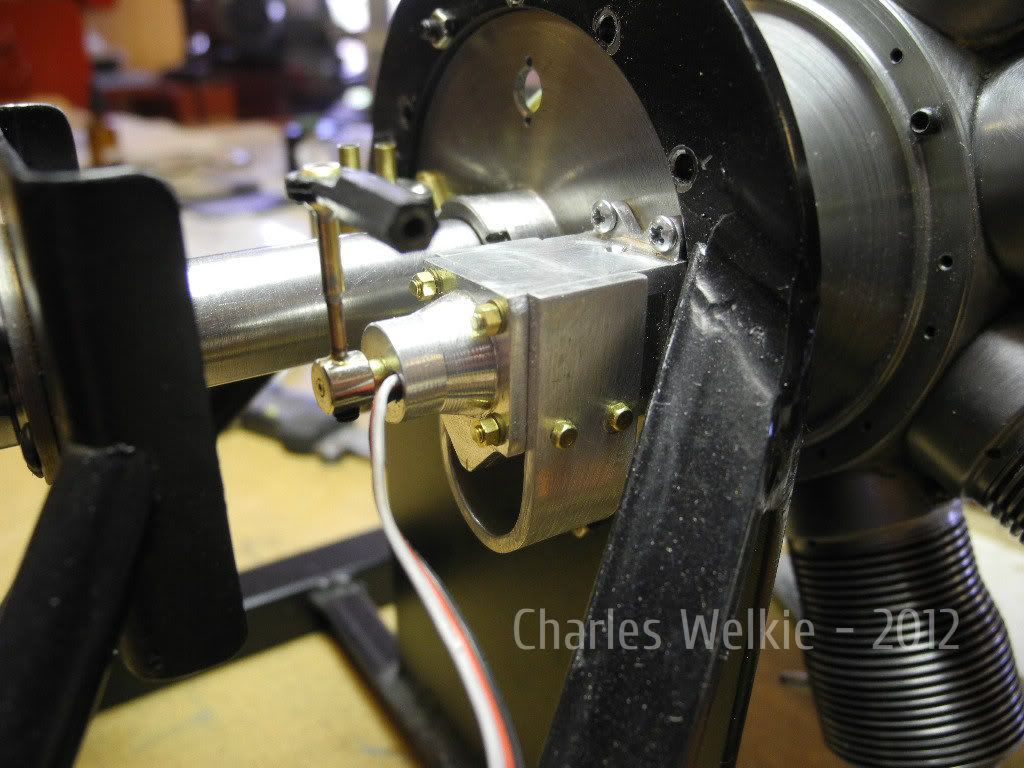

The oil pump. Not scale but very functional - typical gear pump driven off the accessory drive via a worm gear

The dummy magneto. It houses two magnets on a rotating disk and an adjustable mount for a hall effect sensor

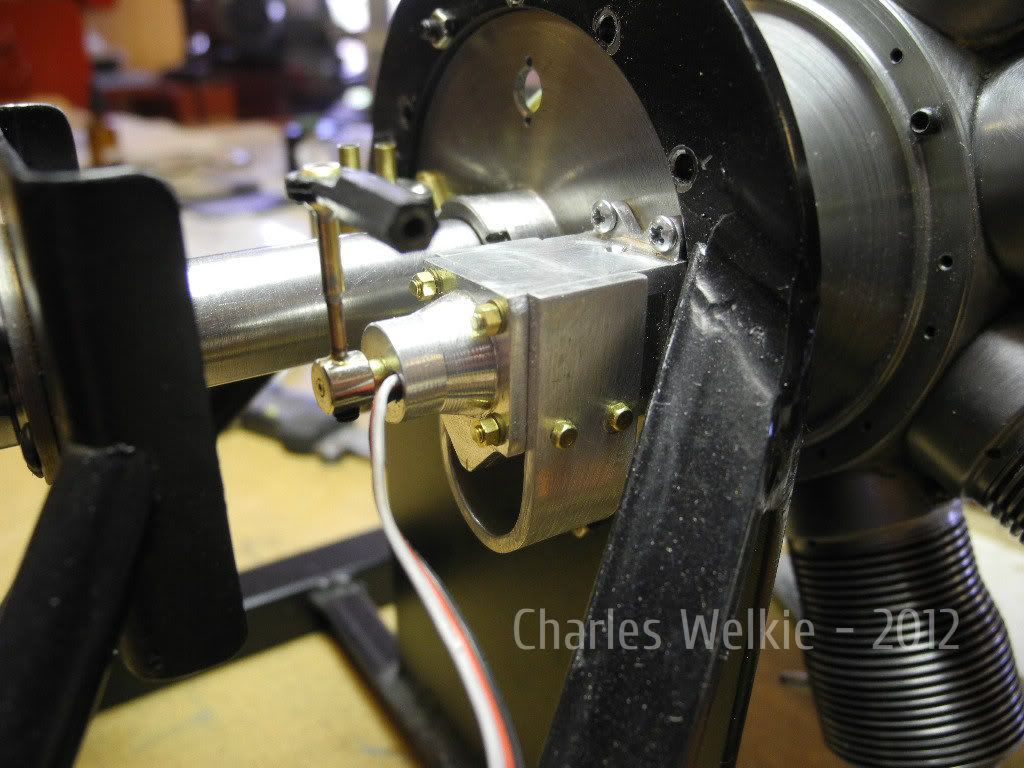

Both rear accessories together (Yes I know - the Phillips screws must go!)

Now the nameplate. It fits to the front crankcase cover under #1 cylinder. Sorry for the cross-post ... It was engraved on my homemade cnc router.

... It was engraved on my homemade cnc router.

That's it for now.

Charlie

Just thought that you might like to see some of the recent progress ...

First - one of the spark plugs. Corian insulator with a 10-32 thread. (Sorry - I should have held the camera focus on the plug ...)

The propeller hub - still without it's splines for the "washer". (Need to make the broach before I'll be happy cutting the splines into the hub.)

The oil pump. Not scale but very functional - typical gear pump driven off the accessory drive via a worm gear

The dummy magneto. It houses two magnets on a rotating disk and an adjustable mount for a hall effect sensor

Both rear accessories together (Yes I know - the Phillips screws must go!)

Now the nameplate. It fits to the front crankcase cover under #1 cylinder. Sorry for the cross-post

That's it for now.

Charlie