glue-itcom

Well-Known Member

- Joined

- Apr 10, 2013

- Messages

- 216

- Reaction score

- 298

A very brief video showing the steering wheel and worm gear operating

Hi Pete, Yes, I think they will be a challenge. I'm not going to split them, I think I will use grooves pin/bolt running in the groove to align. Thanks, NigelLooking good, Nigel!

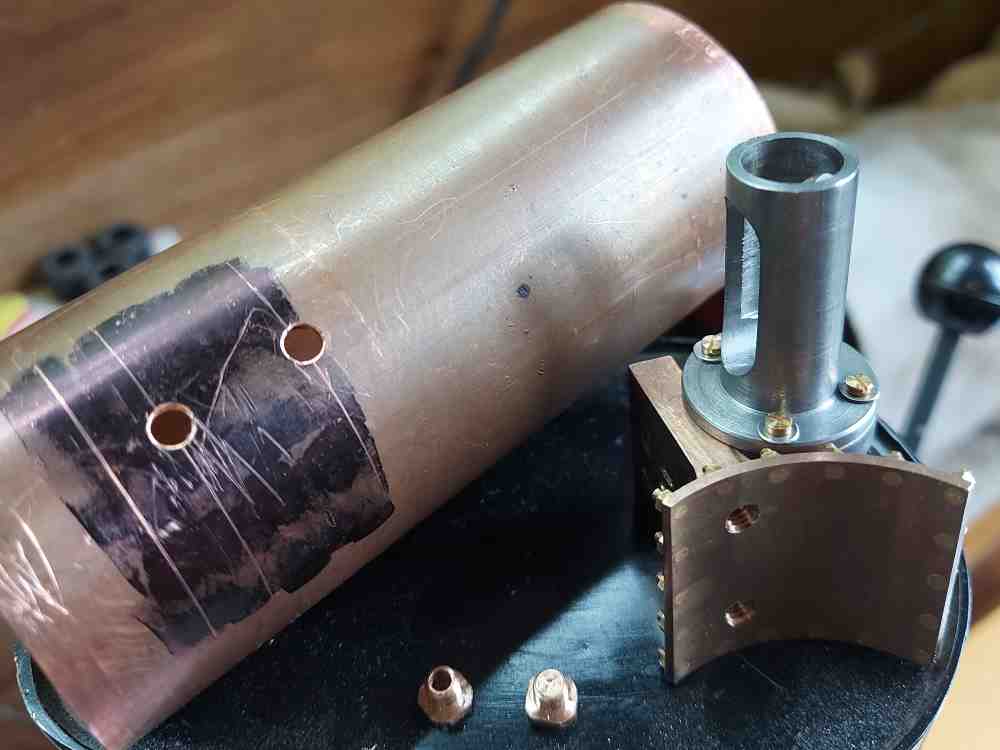

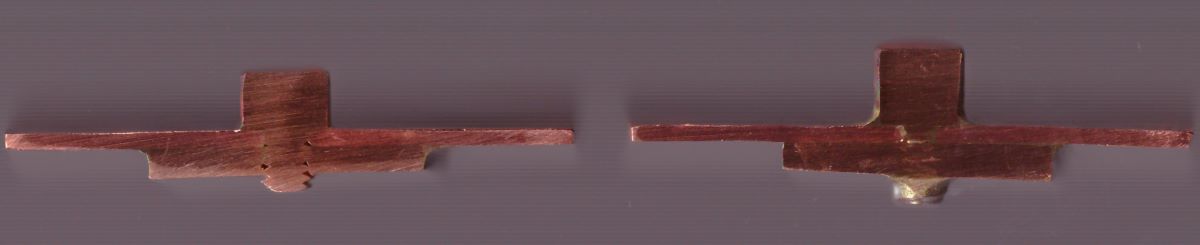

Next challenge will be clearance for the eccentric straps.

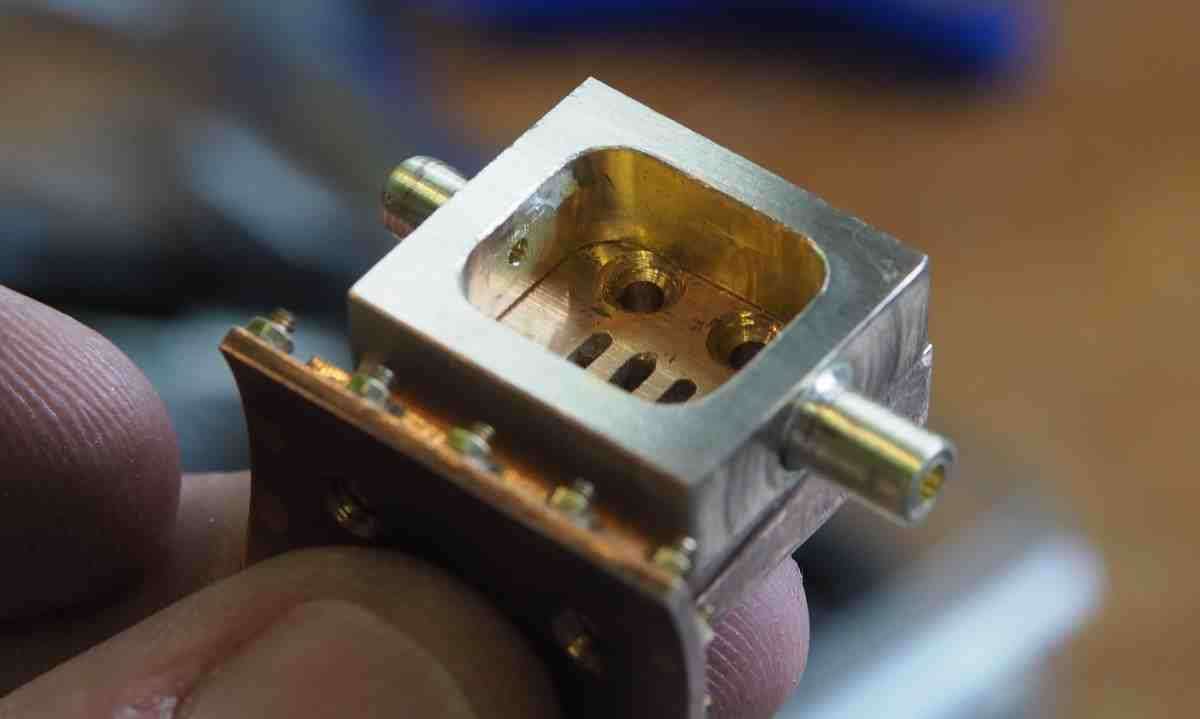

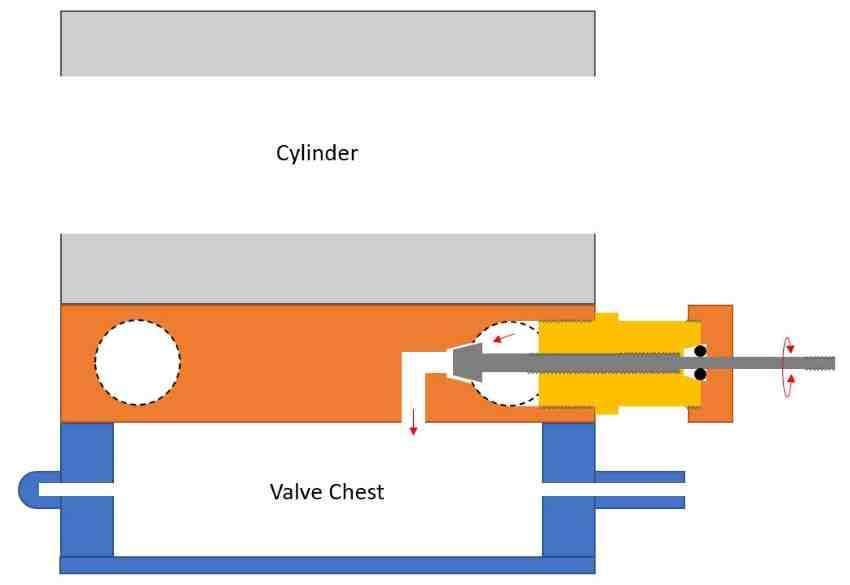

Hi Pete, I do keep coming back to that approach. I may have to see if I can find some very small valve designs. Thanks, NigelHi Nigel,

My own preference would be towards creating the valve within the saddle, perhaps even using some parts of the standard valve.

Not the easiest option, but I am one for spending several hours on a single detail.

Other opinions may vary.

Pete.

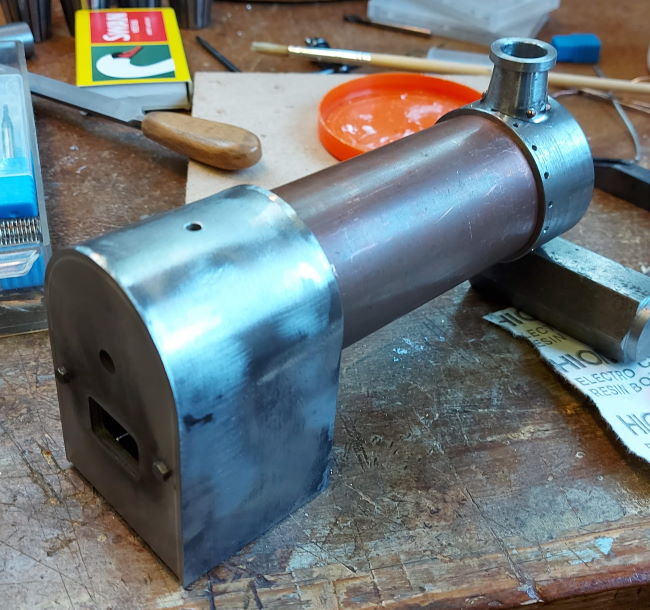

Hi Dave,Hi Nigel, love your build so far. Are you going to put a sight glass on the rear of your boiler if so you could come off of it with your valve and then on to the valve box. You could still use the one coming up into your valve box straight up to the safety valve and save some precious heat loss by only running steam one way from your valve. Just a thought your build has helped lots on my build of the myfordboy traction engine. Especially making the saddle fit my boiler with a fly cutter. It saved me lots of trial and error. Thanks Dave (Smittman)

Enter your email address to join: