deere_x475guy

Well-Known Member

Man has it been fun looking through everyones lathes and shops. I could spend all day looking at this stuff....

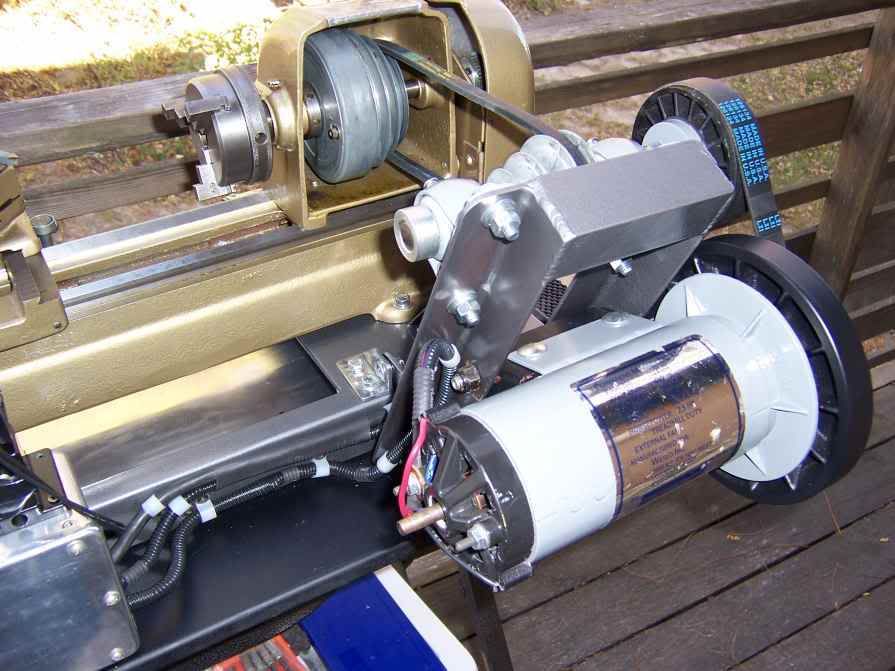

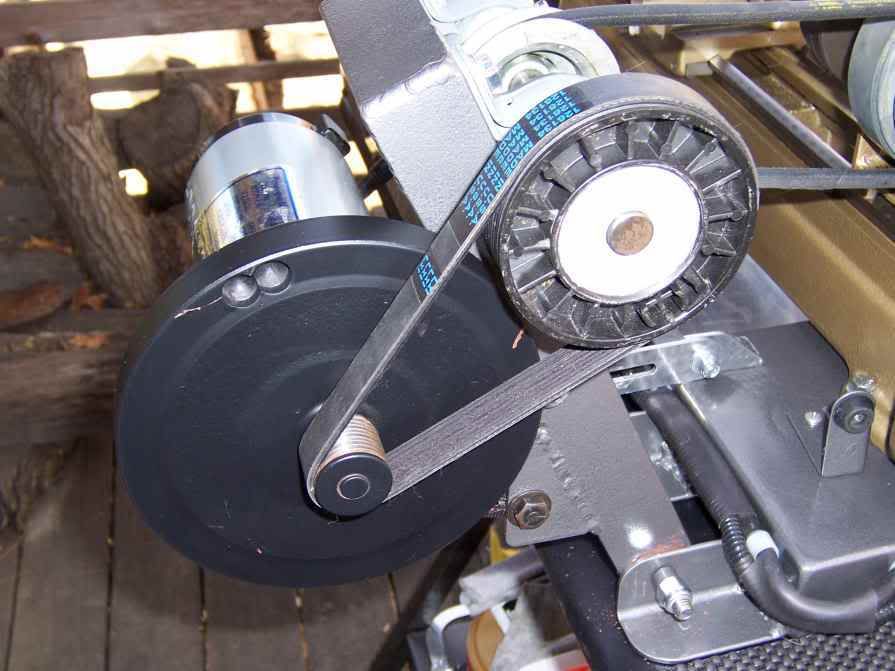

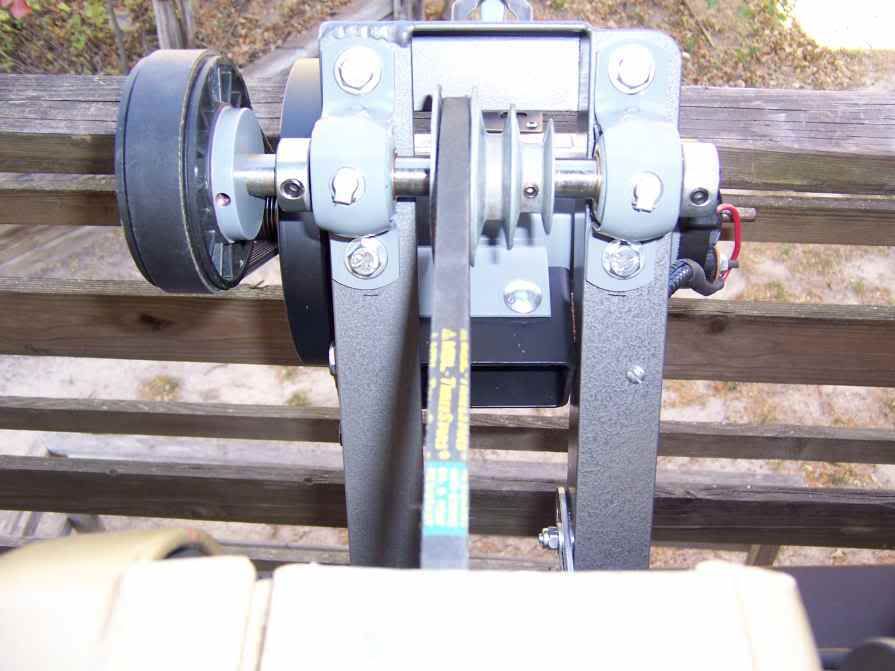

Here is my current lathe. I started out with a 7 x 10 mini and sold it to add money to get a 9 x 20. Sold that to get money to get the 13 x 40 I have now. I am actually planning on getting another 7 x 10 after the first of the year to do the very small parts that the higher speed will help.

Here is my current lathe. I started out with a 7 x 10 mini and sold it to add money to get a 9 x 20. Sold that to get money to get the 13 x 40 I have now. I am actually planning on getting another 7 x 10 after the first of the year to do the very small parts that the higher speed will help.