I'm getting ready to start on a Webster and I hope to tap into the experience of others who have built one and have much more experience that I do.

I don't have any 3.75" steel or cast iron laying around for the flywheel but I do have a beautiful bronze ring 4.75"OD, 3"ID, .866 thick. It's a bit bigger than the design calls for. It would be easy enough to raise everything by the .5" increase in radius. Will the increased mass of the flywheel or increasing the height of the engine be an issue?

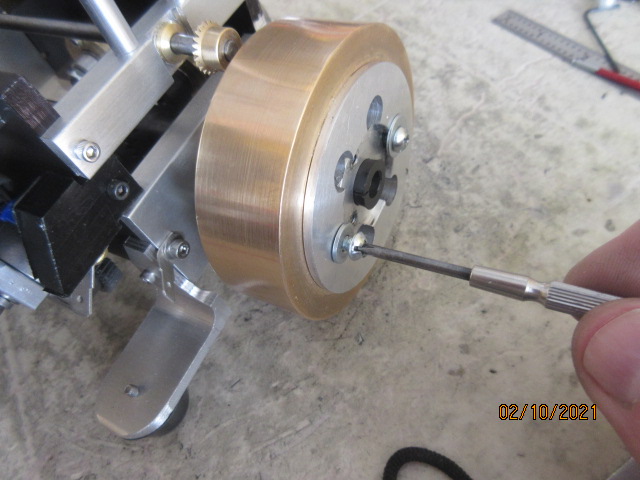

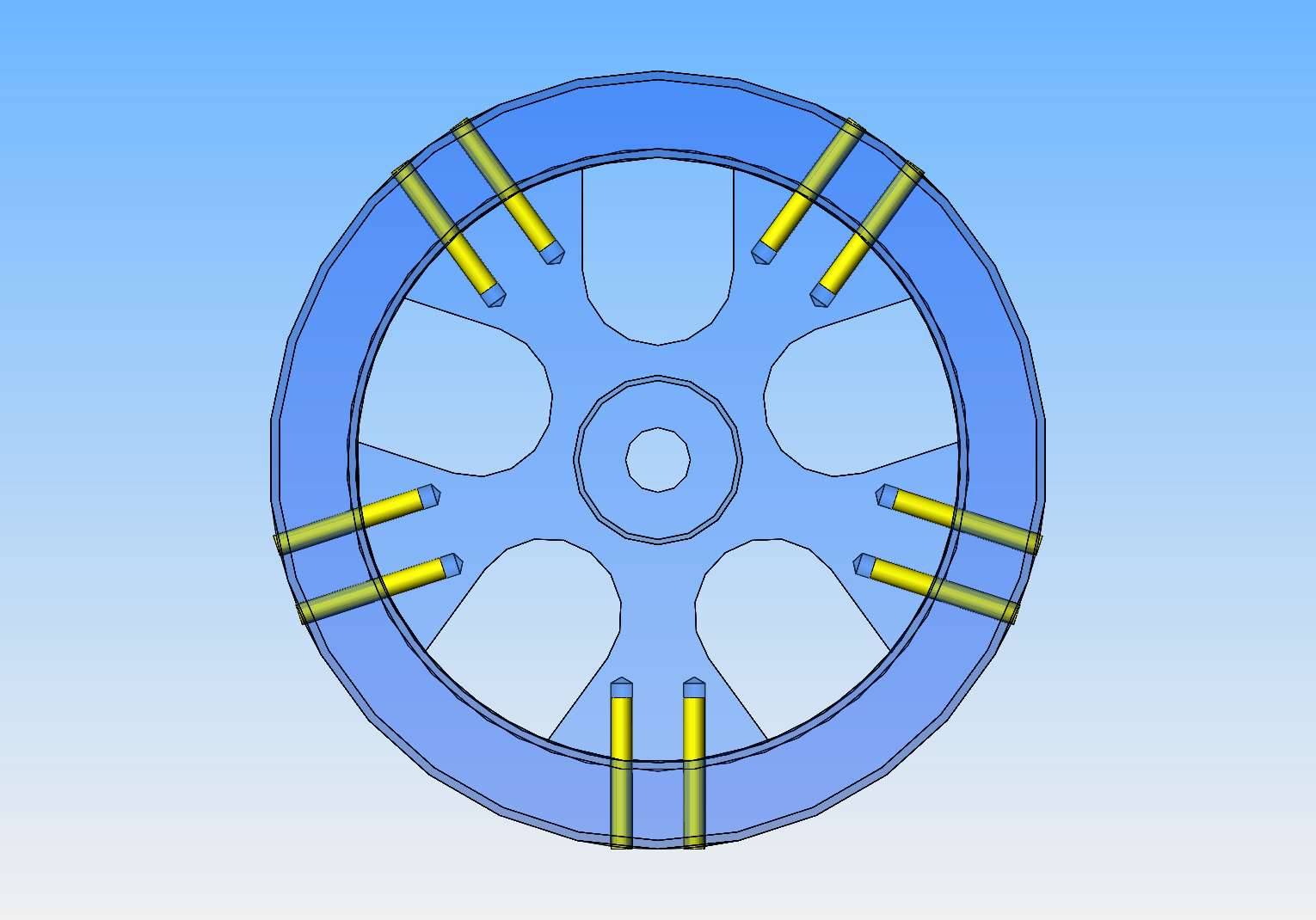

This would have to be a two-piece flywheel. I was thinking about cutting a step in the center an press fit a disk with the hub into the ring. Any suggestions on where to look for two-piece flywheel construction ideas?

I don't have any 3.75" steel or cast iron laying around for the flywheel but I do have a beautiful bronze ring 4.75"OD, 3"ID, .866 thick. It's a bit bigger than the design calls for. It would be easy enough to raise everything by the .5" increase in radius. Will the increased mass of the flywheel or increasing the height of the engine be an issue?

This would have to be a two-piece flywheel. I was thinking about cutting a step in the center an press fit a disk with the hub into the ring. Any suggestions on where to look for two-piece flywheel construction ideas?