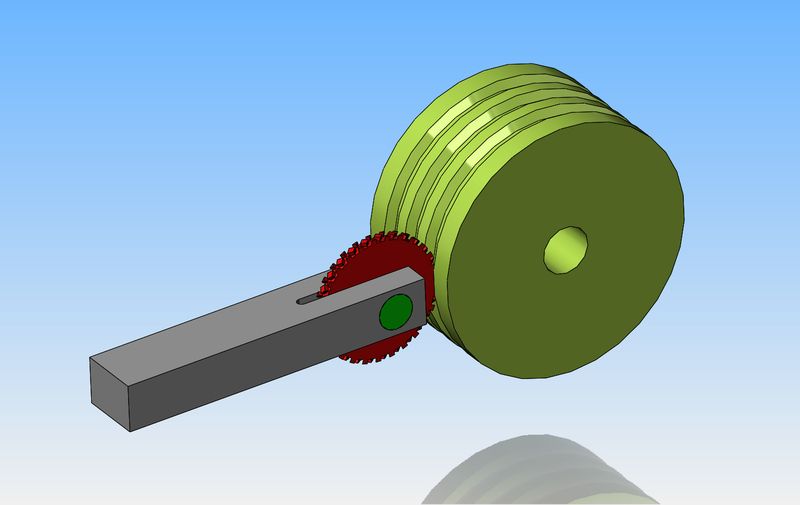

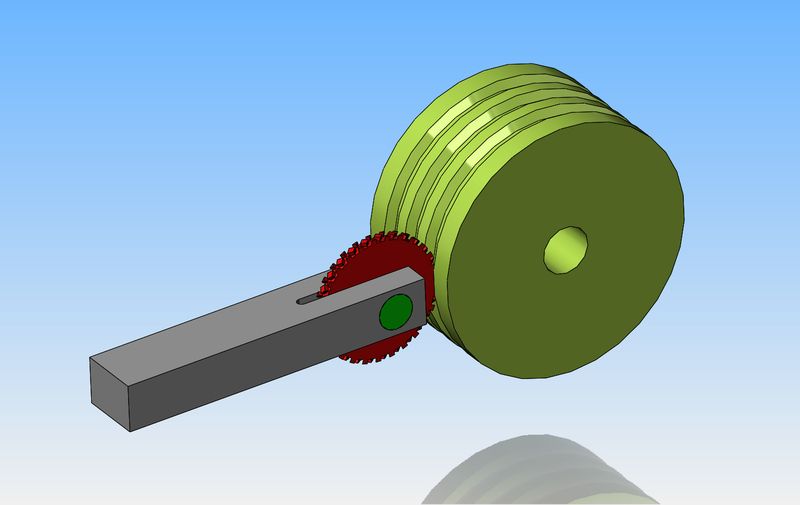

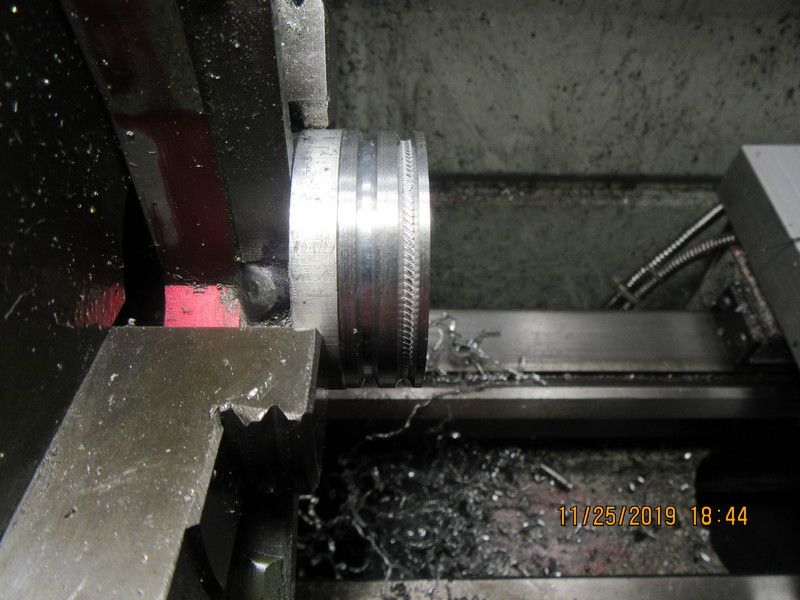

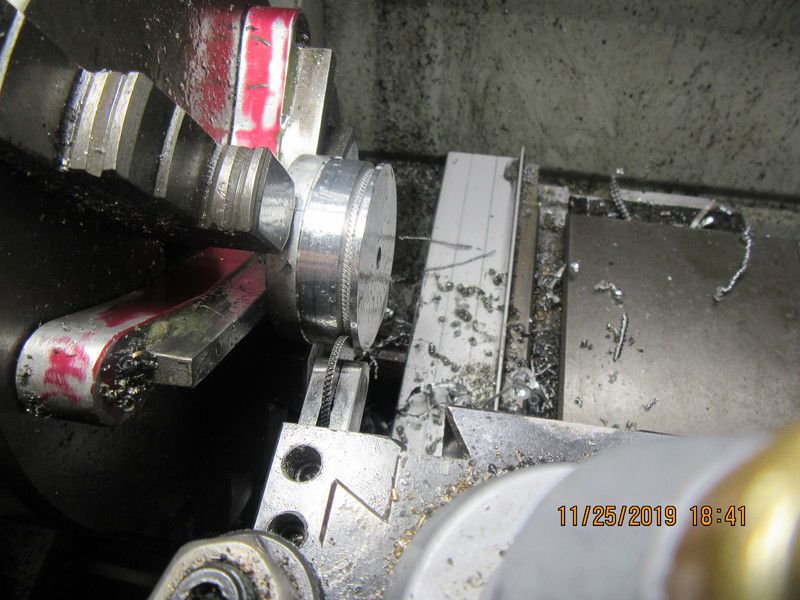

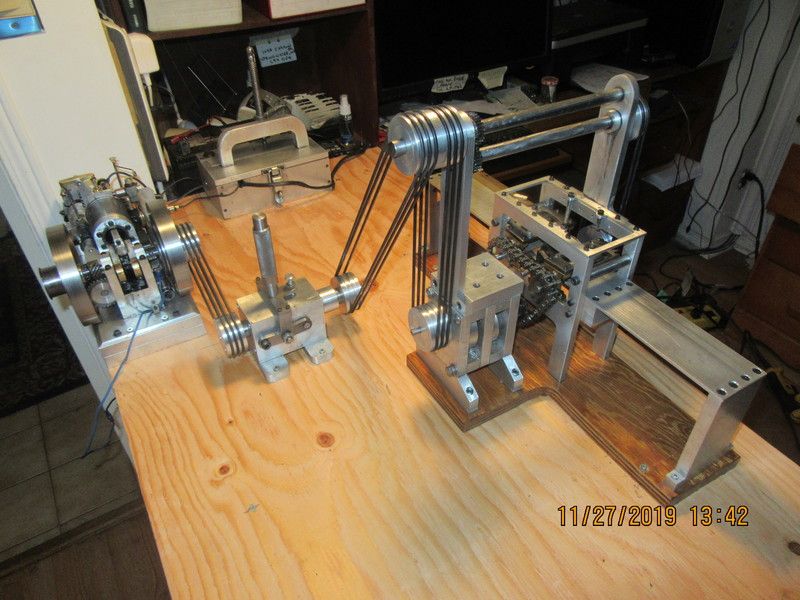

I'm still waiting for O-rings, but in the meantime, the brain never rests. I'm still thinking of a pattern embossed on the aluminum pulley in the area where it connects with the o-ring. The o-ring gets squeezed into a v-shaped slot with a flat bottom. If the sides of the v-shaped slots have an embossed pattern, I can imagine it tearing up the rubber O-rings fairly quickly. However, if the pattern was embossed only on the flat in the bottom of the groove, it would supply a lot of traction ensuring that the O-rings would be far less apt to slip, yet not tear up the O-rings. This makes the roller easier to fabricate. I can do a heavy knurl on the outside diameter of a 1" diameter piece of 01 steel, then part of a slice .075" wide and harden it. After heat treating it, put it in a handle as shown, mount the aluminum pulley on a mandrel and drive the pulley with my lathe. With the knurled piece held in my Q.C.toolpost lined up with the flat in the bottom of the pulley, then just crank the cross feed down tight and let the pulley make a few revolutions. I have never seen this done, but it seems like a good idea.