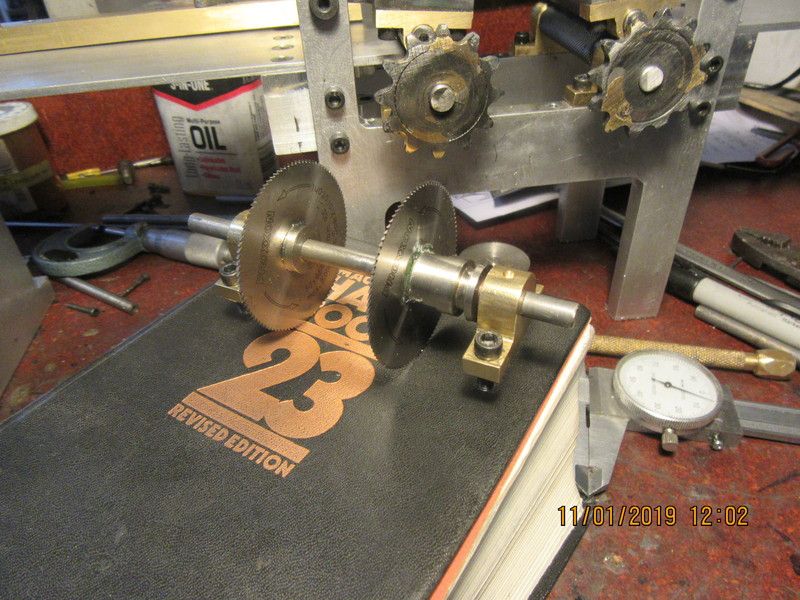

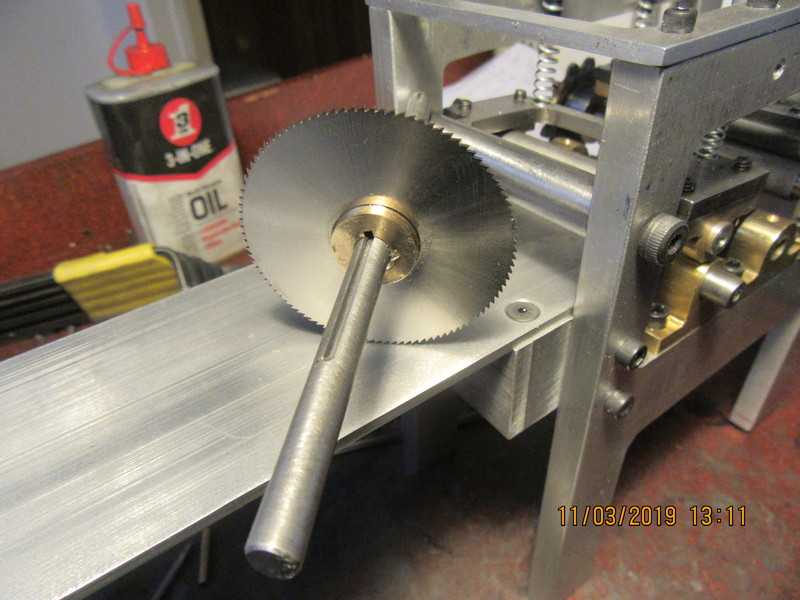

I spent a large portion of my morning "fine tuning" my "pillow block" bearings. Real pillow block bearings are self aligning, whereby the actual bearing unit can orbit in the cast iron housing to prevent any binding. My one piece simulated pillow blocks weren't nearly as forgiving. When they were tightened down to the aluminum frame, the shafts were binding very badly and wouldn't rotate. The misalignment was very small. So small that conventional machining wouldn't / couldn't fix it. My reamers are too short to span across both sides of the frame. I ended up coating dummy shafts with #600 aluminum oxide paste and lapping (for lack of a better word) with my electric drill. The dummy shafts were, of course, made long enough to span across the frame and fit through two opposing bearings at once. During the process I removed the bearings one at a time for polishing and the addition of "oil holes". Final step was to remove bearings one at a time for a bath in laquer thinners, then scrubbed inside with a small brush to remove any remaining grit. Doesn't sound like much, but it eat up my morning. Yesterday it rained all day, and I missed my "Fat mans walk". Today was lovely here, so I walked much farther on the forest trails where I hadn't been before to make up for the missed walk yesterday. It was about 58 F today, and many of the leaves have fallen, but enough remain on the trees that it is still very pretty. Seen a lot of new ground, and my legs are telling me about it tonight.