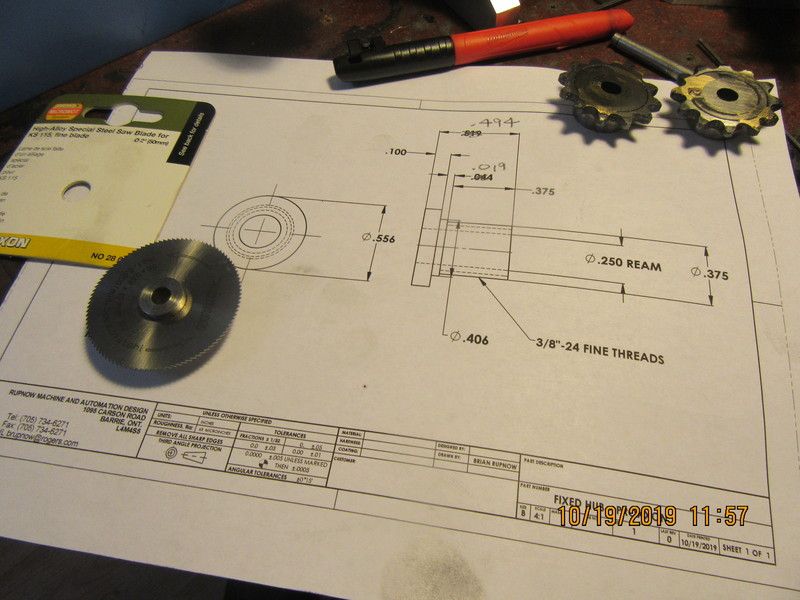

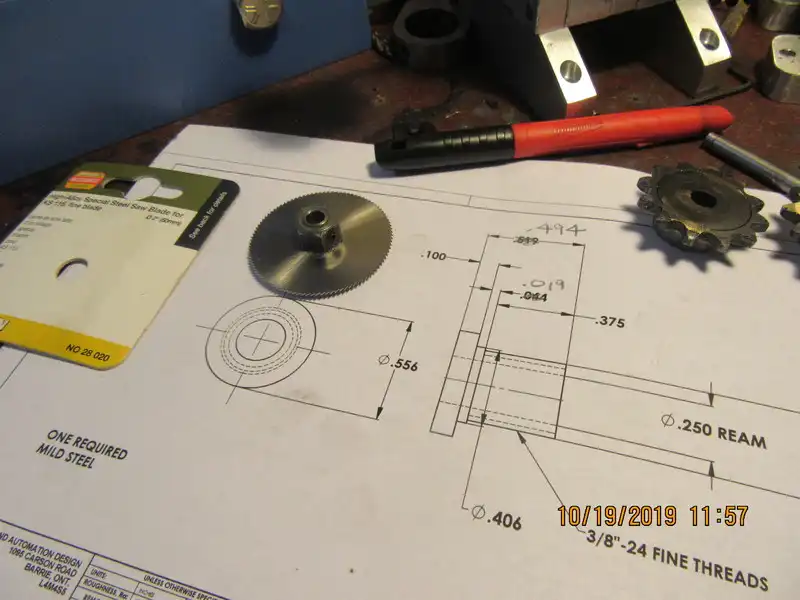

Drove up north to see my 99 year old mom today, and made a side trip on my way back to see my best friend forever who had a stroke. Mom is okay, but has dropped a lot of her memories. Best friend, who is the same age as me had a bad stroke, was in hospital for three weeks and come home yesterday. He has no lasting physical effects, but has aphasia. He can't speak, can't spell, but can understand when others speak to him. He was very frustrated today, trying to tell me things but couldn't speak. He can get a few words out, and I'm sure that over the winter he will regain most of his speaking ability. One of my 2" diameter Proxxon saw-blades was delivered today, other is on back order. It is very sharp, but has no "offset" to the teeth at all. I really wish I had access to small inexpensive toothed belts and pulleys, but since I don't I will use O-rings instead.