I have looked back over your build, and I see you used 12L14 steel for your cylinder. That would work fine with Viton rings, but I am not sure that it will work with the cast iron rings you used. Iron has a lot of "free graphite" in it's molecular structure, so is to a large extent self lubricating. Cast iron rings running in a cast iron cylinder is the standard formula that always work well together. I don't know if your cast iron rings will "bed" in that 12L14 steel cylinder or not.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Werowance builds a webster

- Thread starter werowance

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

watch my video:

If, there is no compression

unscrew the cylinder head, seal the cylinder head by hand, the compression force as in my video or more: cylinder and piston ok

-> check valve again

With intake valve springs, it only needs to hold the valve in the closed position !

With the exhaust valve spring, because valve is open by cam, its stronger no problem

If, there is no compression

unscrew the cylinder head, seal the cylinder head by hand, the compression force as in my video or more: cylinder and piston ok

-> check valve again

With intake valve springs, it only needs to hold the valve in the closed position !

With the exhaust valve spring, because valve is open by cam, its stronger no problem

Cogsy

Well-Known Member

The 12L14 won't be a problem with cast iron rings - Steve Huck uses that combination in his multi-cylinder engines and they work perfectly. I would be trying some new fuel myself as I find it tough to believe that all the volatiles have hung around in your Coleman for 15 years - no can is that impermeable. Also, on the nitro, I assume you mean methanol with some % of nitro in it. If so, the needle settings for running on alcohol are far different than those for petrol/gasoline. I'd grab some brand-new gasoline so you know it's good, and start from there. Your ignition timing can be out a bit, even your cam timing can be a smidge off, but if it has good fuel, with roughly the right amount of air, enough compression and a spark, it will run. Good luck!

- Joined

- Sep 2, 2011

- Messages

- 1,342

- Reaction score

- 360

ok, last night I tried 40 to 1 weedeater gas oil mix and it hit hard tried to start but it wouldn't. I started hand turning it over and it no longer has that nice push back from compression that I had before it broke in. I pulled the head and cylinder off together and removed valve assembly, piston and plug. I plugged the spark plug hole and the back of the cylinder with my hands and applied suction on the intake exhaust hole on head and it held suction so the head gasket was sealing properly.

then I inspected the rings and I think I found my problem. in the first picture you will see a dark section on the ring. this is not a shadow. this is where the ring is not rubbing or has not broken in. the other ring has this as well but not as much. this is exactly opposite side to the split in the ring. so I'm pretty sure this is the loss of compression I now have. oh well I think I posted further back that I fully expected to have to go with vititon oring for my first ic engine and looks like I'm going to have to do that. ill be looking back at Brians build to see what oring he got and dimensions of it. and also on my lunch break I hope I can swing by the auto parts store and pick up an assortment of them. hopefully if I'm lucky ill find one that fits my top ring groove in my existing piston and I wont even have to make a new one (doubt that actually works out that way though but wouldn't it be nice if it did).

then I inspected the rings and I think I found my problem. in the first picture you will see a dark section on the ring. this is not a shadow. this is where the ring is not rubbing or has not broken in. the other ring has this as well but not as much. this is exactly opposite side to the split in the ring. so I'm pretty sure this is the loss of compression I now have. oh well I think I posted further back that I fully expected to have to go with vititon oring for my first ic engine and looks like I'm going to have to do that. ill be looking back at Brians build to see what oring he got and dimensions of it. and also on my lunch break I hope I can swing by the auto parts store and pick up an assortment of them. hopefully if I'm lucky ill find one that fits my top ring groove in my existing piston and I wont even have to make a new one (doubt that actually works out that way though but wouldn't it be nice if it did).

My engine does not need rings and still runs for a long time, so I think your engine is also not necessary, unless you want the piston to have it !

personal opinion : focus on compression, just have compression it will run!

run well or not, leave later.

personal opinion : focus on compression, just have compression it will run!

run well or not, leave later.

Werowance-- Use only one Viton ring 1/16" nominal cross section. (actually 0.070") Outside diameter of Viton ring same as cylinder bore. Slot in piston 0.094" wide (parting tool width) x 0.056" to 0.058" deep. Do not use a standard butyl rubber ring. One thing you could try before pulling everything apart---Sacrifice a sparkplug by breaking away all the ceramic and the inner electrode and solder a short piece of metal tubing onto it. Slip a piece of flexible tubing over that, screw it back into the cylinder head, and put some air to it. When the piston is at the top of it's compression stroke, you can easily tell if air is coming from the exhaust--leaky exhaust valve. If air is coming out of the carburetor---leaky intake valve. If air is coming out past the piston, then your rings are bad. Just be AWARE--Hang onto the flywheel so it doesn't begin to rotate off top dead center or it will take off like a rocket for bottom dead center.

Last edited:

Cogsy

Well-Known Member

For a quick and dirty test of your rings you could add a drop or two of oil in the plug hole and see how much your compression increases.

I wouldn't expect your rings to be seating properly until the engine has a reasonable amount of run time (maybe 15 minutes?). Seal will improve the more combustion cycles it sees and if it's consistently hitting then it has enough compression for combustion and should run. My guess is your carb settings are off slightly. A bit of tweaking and I believe it will run as it is.

I wouldn't expect your rings to be seating properly until the engine has a reasonable amount of run time (maybe 15 minutes?). Seal will improve the more combustion cycles it sees and if it's consistently hitting then it has enough compression for combustion and should run. My guess is your carb settings are off slightly. A bit of tweaking and I believe it will run as it is.

- Joined

- Sep 2, 2011

- Messages

- 1,342

- Reaction score

- 360

Cogsy so that little bit of not wearing bright and shiney on the exact opposite end of the split on the ring would be normal until more running? i probably have about 30 mins to an hour of runt time with electric drill power on them. the thought of them still being ok excites me as i figured the rings and piston were trash at this point. glad i didn't toss anything just yet and start over.

also don't know if i mentioned it but my brother and i bought a saw mill a couple weeks ago. taking a little break away from the engine (couple days only so far) has helped as well and that saw mill is the coolest toy next to the lathe and mill i have ever owned - or half owned before.

also don't know if i mentioned it but my brother and i bought a saw mill a couple weeks ago. taking a little break away from the engine (couple days only so far) has helped as well and that saw mill is the coolest toy next to the lathe and mill i have ever owned - or half owned before.

Cogsy

Well-Known Member

I can't guarantee that the ring will fully seal, but until it's had some good actual running time you just can't know. Because it's got enough compression to fire it is my best guess that your settings are just off enough that it won't run on it's own and it highly likely to be your carb needle settings. Once you get the setting close enough I believe it will run and you can then tweak more so it runs it's best. At this point you will have higher combustion pressures which will attempt to expand your rings into the bore and they will then bed-in reasonably quickly. You can expect compression to increase over the first 10-15 minutes of actual running time but if your rings are still leaking after 30 minutes of real running then they're probably never going to fully seal. Of course at that point you have to wonder, if the engine runs nicely, do you really need to bother to improve the compression.

Short story - I believe it will at least run on it's own power with your current piston and rings.

Short story - I believe it will at least run on it's own power with your current piston and rings.

We're all on the edge of our seats here, wondering whats happening.---Brian

- Joined

- Sep 2, 2011

- Messages

- 1,342

- Reaction score

- 360

this weekend I ran in the rings a lot - about 2 hours worth. compression has increased a lot. last night I had about 30 mins of play time so I tried starting it. both on 40 to 1 gas and on the old coleman fuel. this time coleman came in first as the most hits.

the engine will hit almost every other hit, and will sometimes actually try to take off. the cylinder was hot as all get out by the time I quit tinkering with it last night. I'm thinking with a little timing adjustment and better coleman fuel I may get it to run.

I know it fires on both compression as well as exhaust stroke, but it does sound as if its firing through the muffler each hit. is this the normal sound? wondering if either cam time is off or if I may have a leaky exhaust valve.

hope to get to Walmart after work and pick up a new can of coleman fuel for tonight.

the engine will hit almost every other hit, and will sometimes actually try to take off. the cylinder was hot as all get out by the time I quit tinkering with it last night. I'm thinking with a little timing adjustment and better coleman fuel I may get it to run.

I know it fires on both compression as well as exhaust stroke, but it does sound as if its firing through the muffler each hit. is this the normal sound? wondering if either cam time is off or if I may have a leaky exhaust valve.

hope to get to Walmart after work and pick up a new can of coleman fuel for tonight.

- Joined

- Sep 2, 2011

- Messages

- 1,342

- Reaction score

- 360

posting factory settigns for the traxxas pro 15 carb here for mine and anyone elses reference. copied from traxxas forum.

and a question, when working on starting issues I guess one would worry with the low speed adjustment and not the high speed right? which ive been working with the large high speed screw for testing. I didn't know the low speed was the screw on top of the throttle lever. I just thought that was what held the lever in place.

begin paste from forum:

The first adjustment should be your idle speed. Set your throttle opening to 1.5mm open with the throttle arm pushed all the way towards the head of the engine. Next, set your low speed mixture to 1 3/4 turns out from bottom. Last, set your high speed mixture setting to 2 1/4-2 1/2 turns out from bottom.

and a question, when working on starting issues I guess one would worry with the low speed adjustment and not the high speed right? which ive been working with the large high speed screw for testing. I didn't know the low speed was the screw on top of the throttle lever. I just thought that was what held the lever in place.

begin paste from forum:

The first adjustment should be your idle speed. Set your throttle opening to 1.5mm open with the throttle arm pushed all the way towards the head of the engine. Next, set your low speed mixture to 1 3/4 turns out from bottom. Last, set your high speed mixture setting to 2 1/4-2 1/2 turns out from bottom.

- Joined

- Sep 2, 2011

- Messages

- 1,342

- Reaction score

- 360

Cogsy

Well-Known Member

I haven't used an RC carb on a model engine that I've built, but I know from experience with RC planes that they can be fiddly to set up. The low speed will be what you need to adjust to get your engine running. Then the throttle response will be based on adjusting both needles, although mainly the high speed once you really get the low speed dialed in.

The carbs I normally make are simpler and generally only have one needle. They can still be very finicky about the needle setting to get the engine fired up, especially when it's new. I would doubt your purchased carb will be spot on the correct setting straight out of the box so I would think that's where you need to look first, before you worry about fine tuning cam timing.

The carbs I normally make are simpler and generally only have one needle. They can still be very finicky about the needle setting to get the engine fired up, especially when it's new. I would doubt your purchased carb will be spot on the correct setting straight out of the box so I would think that's where you need to look first, before you worry about fine tuning cam timing.

Surprisingly enough, all the Traxxas carburetors I buy come set exactly to what the internet settings say. And the original settings don't change very much at all to run our little engines. The only adjustment I mess with is the external idle adjustment screw.

- Joined

- Sep 2, 2011

- Messages

- 1,342

- Reaction score

- 360

last night I set the carb back to factory spec, brand new coleman fuel and still no start. lots and lots of pops. cylinder heating up etc. I even went as far as to rotate ign cam a full 360 deg at about 5 deg per try. once I hit it firing on exhaust my wife came out of the house and gave me the thumbs up thinking I had it running.... but alas I did not.

this morning re-reading the timing on both ign and valve I may have hit on at least one thing I think I was doing wrong and one thing to just double check.

ign cam:

rotate it clockwise until the points close and just start to open.

- on this I was setting until the points just start to close not close then open. but the trial of rotating 360 deg I think should have covered that but maybe I missed it. ill check that tonight

valve timing:

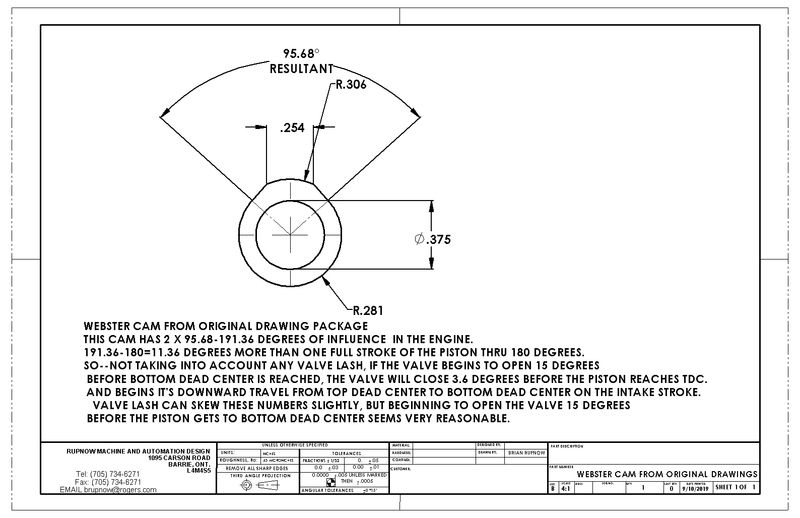

If set properly, the exhaust valve will close a few degrees before TDC.

- on this I did not verify that part, however as per instructions at 15deg it just starts to move the valve - I do have adjustment here if need be - very little but I can raise the tappet screw just a bit. but ill verify this tonight.

on fuel- I can definitely smell a difference in old (15 years or more old) coleman vs just bough yesterday coleman however I really didn't notice any difference in how hard the engine was hitting or firing.

this morning re-reading the timing on both ign and valve I may have hit on at least one thing I think I was doing wrong and one thing to just double check.

ign cam:

rotate it clockwise until the points close and just start to open.

- on this I was setting until the points just start to close not close then open. but the trial of rotating 360 deg I think should have covered that but maybe I missed it. ill check that tonight

valve timing:

If set properly, the exhaust valve will close a few degrees before TDC.

- on this I did not verify that part, however as per instructions at 15deg it just starts to move the valve - I do have adjustment here if need be - very little but I can raise the tappet screw just a bit. but ill verify this tonight.

on fuel- I can definitely smell a difference in old (15 years or more old) coleman vs just bough yesterday coleman however I really didn't notice any difference in how hard the engine was hitting or firing.

Set the engine so that piston is 15 degrees before top dead center. Take the sparkplug out and lay it on the head or anywhere on the metal body that you can see it but leave power to sparkplug on. Loosen off the ignition cam grub screw and make sure that the flat part of the cam is contacting the rubbing block on the points. Now turn the ignition cam in the direction the engine would normally turn. as soon as the cam opens the points, you will see and hear a spark occur. That is the point at which you lock down the ignition grub screw.

Mechanicboy

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 955

- Reaction score

- 341

You can not use the carburator who are adjusted for methanol, much less counts of turns on needle... Also the engine running at gasoline or coleman fuel need less turns on needle for high mixture and idling mixture. My engine is running with 1/2 turns of main needle for gasoline, not more. If running on methanol, then the counts turns of needle is more up to 2 1/2 - 3 turns.

- Joined

- Sep 2, 2011

- Messages

- 1,342

- Reaction score

- 360

Mechanicboy, I'm running the same Carb that Brian used on his Webster. traxxas pro 15. what is your carb model? and what fuel are you running on? and what engine as well? I ask to see if its all the same as what I am running.

Similar threads

- Replies

- 2

- Views

- 825