So, here it is guys.--First run. I tried to get it to start for about half an hour. It would fire and run if I put a few drops of gasoline down the sparkplug hole, but then die off once those few drops were burned. This lead me to believe that the spring on the atmospheric intake valve was too strong. I removed the spring and cut two coils off, then reinstalled it. The engine started right up, as you see in the video. My next trick will be to get the engine running properly with the hit and miss lever in place.---Brian

.

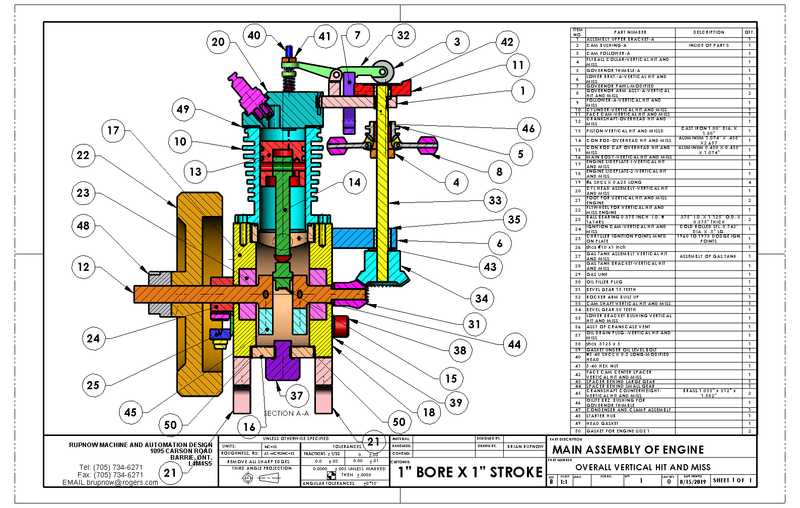

Great running engine