I had my second eye surgery for cataracts this morning, and everything went amazingly well. Great news about my left eye, the one I had done two weeks ago. It has improved a lot over the past two weeks and will not require any further surgery. Now I get to wait 4 weeks until I go see my usual optometrist to see what glasses I will need. Today is the first time I've been able to read my email without any glasses on for many, many, years. Why, just looking out my back door I can see Giants turning cart-wheels, statues wearing high-heels----

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Verical hit and miss engine

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Look at all the happy creatures dancin' on the lawn.

Good to hear it went well.

Good to hear it went well.

JohnBDownunder

Well-Known Member

- Joined

- Mar 1, 2012

- Messages

- 109

- Reaction score

- 28

Glad it all went well for you Brian, trouble now is that you will see some of the teensy, tiny faults you missed before getting your eyes fixed. ha ha.

As a surgeon (who was about to sew several tendons back in position for me after a tumble that tore em.) Cataract and joint replacement are the ones that give almost immediate relief. Thus making them the best to have when needed I guess.

I know from personal experience that a hip replacement done right is brilliant - pain is all gone, doc when can you do the other one? "Not until it gets much worse mate."

John B

As a surgeon (who was about to sew several tendons back in position for me after a tumble that tore em.) Cataract and joint replacement are the ones that give almost immediate relief. Thus making them the best to have when needed I guess.

I know from personal experience that a hip replacement done right is brilliant - pain is all gone, doc when can you do the other one? "Not until it gets much worse mate."

John B

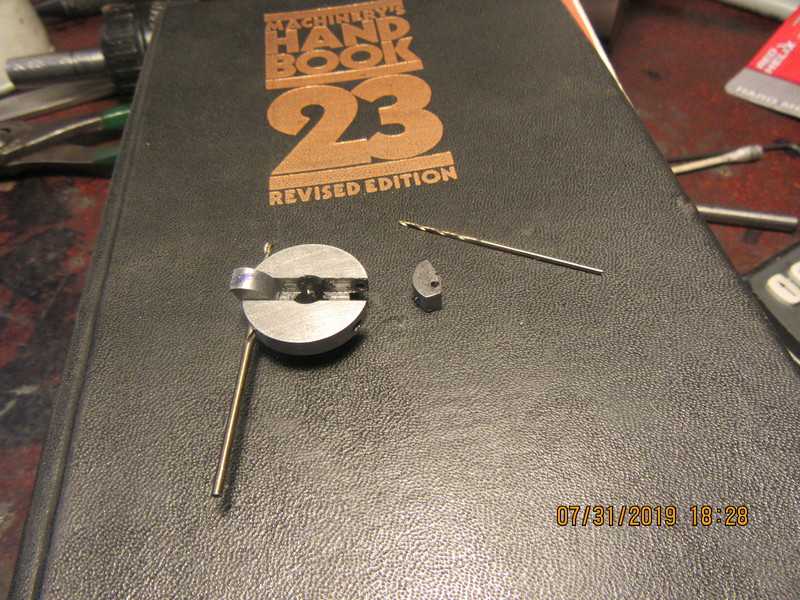

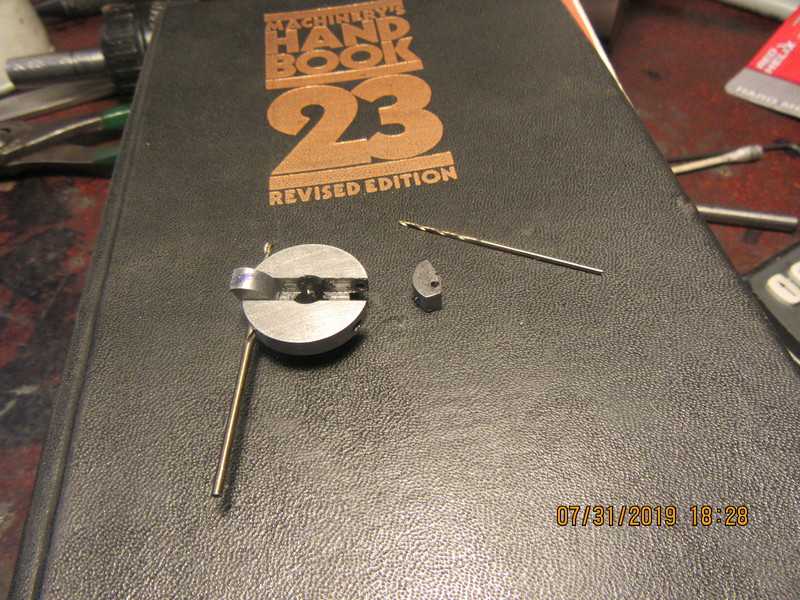

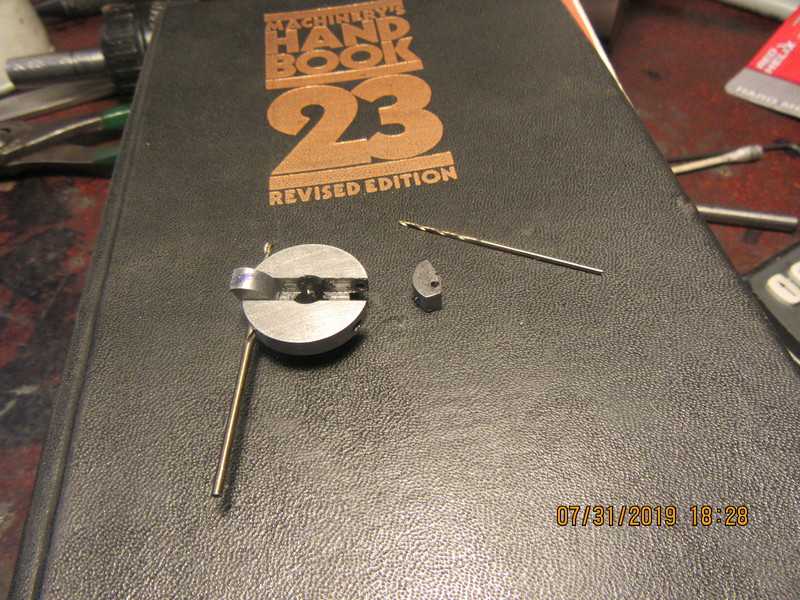

Nothing earth shattering made today, but I'm being very careful of not aggravating my new eyes. I did manage to make the governor thimble from 01 steel and harden it, and pressed a 1/4" i.d. oilite bronze into the bore. The thimble has to slide up and down on the shaft, and I figured steel on steel wouldn't do very well.

Today I'm right down into George Britnell territory. These governor weights are right at the lower limit of what my new eyes can see. Those fly-weights are so small that I just trusted my DRO and kept cutting until they were finished. Tomorrow I will probably go up to the drugstore and buy some cheap "cheater" glasses to use until I can get my new prescription glasses.

Those are the weights? I've got to see the restoring force.

I called them the wrong thing. They aren't the weights. They are the mechanism that lifts the tapered slider in the valve train. The arms and weights attach to those parts.

There doesn't appear to be a smiley for a thumbs up, but I think I see how that's going to work.

My bad, Bob.--It's been a long day.--Brian

Brian, I see you are still using the standard edition of the Machinery's Handbook. I opted for the 'Large Print' version years ago and it made a big difference in how often I refer to it. Much easier to use.Today I'm right down into George Britnell territory. These governor weights are right at the lower limit of what my new eyes can see. Those fly-weights are so small that I just trusted my DRO and kept cutting until they were finished. Tomorrow I will probably go up to the drugstore and buy some cheap "cheater" glasses to use until I can get my new prescription glasses.

Loren--That copy was given to me by the German head of engineering at Volkswagen Canada about 25 years ago, when I worked for Volkswagen. Volkswagen Canada is gone now, and Karl has retired in Germany.

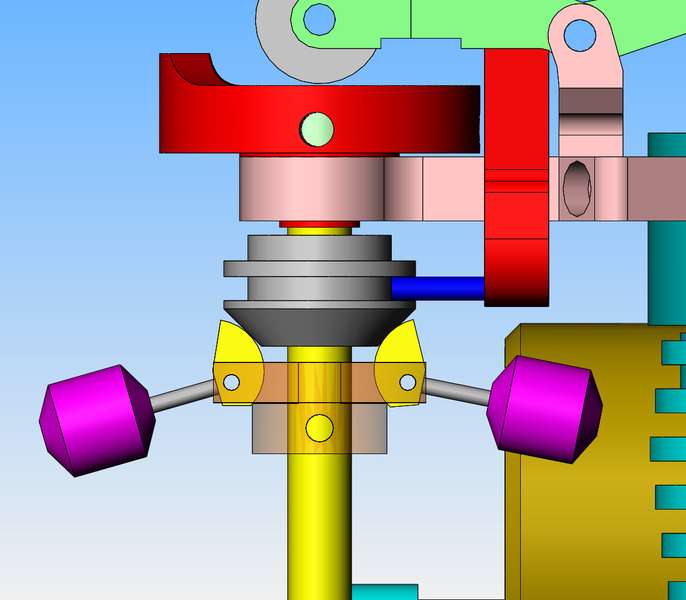

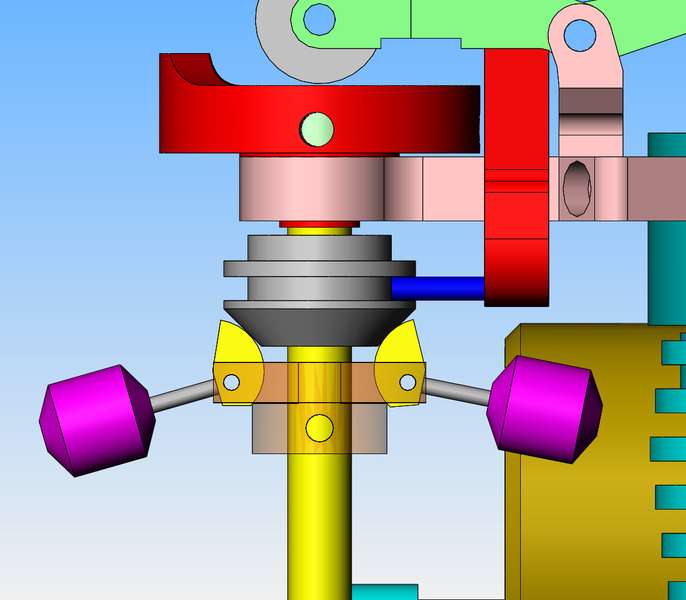

Now that, me darlin's, is a beautiful thing. I don't have a ball turner, so my governor weights are shaped a bit differently from what I originally designed them as. I have to hunt up a proper size compression spring, and then I am almost ready to finish the governor assembly. Then I can move on to a piston, con rod, and crankshaft. The shaft that is in the engine right now is just a plain piece of 3/8" cold rolled.

Brian

What size balls and thread do you need. Alu or steel

Tom

What size balls and thread do you need. Alu or steel

Tom

Tom--Thanks, I'm happy with the weights that I have now. As I tune this engine, I may well find that the ball size has to change to make everything work right. If you look for YouTube videos of the "Silver Angel" engine by Bob Shores, you will see none of the engines shown seem to be "missing' very much. I hope to have better results with this engine.

I've just had one of those days where much work was done but damn little was accomplished. Today I machined that S shaped part which is the governor latch. It works very well. The governor swings it in under the rocker arm to lock out the exhaust valve. I have had it installed, then uninstalled and machined a little bit---repeat---repeat---repeat. The issue is that there is very little difference between the rocker arm position when it is "up" on the cam and "down" off the cam. Literally, thousandths of an inch. At the moment, it is about 0.030" too short, and will happily swing under the rocker arm no matter what position the cam is, either "up" or "down". Tomorrow I will take my trusty mig welder and build the short end up, then reshape and file it and hopefully get it to swing under the rocker only when it is "up" on the cam.

I've just had one of those days where much work was done but damn little was accomplished. Today I machined that S shaped part which is the governor latch. It works very well. The governor swings it in under the rocker arm to lock out the exhaust valve. I have had it installed, then uninstalled and machined a little bit---repeat---repeat---repeat. The issue is that there is very little difference between the rocker arm position when it is "up" on the cam and "down" off the cam. Literally, thousandths of an inch. At the moment, it is about 0.030" too short, and will happily swing under the rocker arm no matter what position the cam is, either "up" or "down". Tomorrow I will take my trusty mig welder and build the short end up, then reshape and file it and hopefully get it to swing under the rocker only when it is "up" on the cam.

Brian,

Hope you're healing from the eye surgery. Don't know if you're doing this for your bi and tri focal lenses. When I had to get bifocals, my late wife told me to get "progressive" lenses. She said I'd be cursing and swearing for a month or two. She was right. Now I love my "progressive" lenses.

Grasshopper

Hope you're healing from the eye surgery. Don't know if you're doing this for your bi and tri focal lenses. When I had to get bifocals, my late wife told me to get "progressive" lenses. She said I'd be cursing and swearing for a month or two. She was right. Now I love my "progressive" lenses.

Grasshopper

davidyat--I tried to wear progressive bifocals, but they made me sick to my stomach. The same kind of sick that you get from drinking too much cheap red wine. I like the old style bifocals much better. I have to wait 4 weeks after my most recent surgery before they will consider prescribing new glasses. They told me that your vision keeps changing for up to 4 weeks after the surgery.---Brian

Tom--Thanks, I'm happy with the weights that I have now. As I tune this engine, I may well find that the ball size has to change to make everything work right. If you look for YouTube videos of the "Silver Angel" engine by Bob Shores, you will see none of the engines shown seem to be "missing' very much. I hope to have better results with this engine.

I've just had one of those days where much work was done but damn little was accomplished. Today I machined that S shaped part which is the governor latch. It works very well. The governor swings it in under the rocker arm to lock out the exhaust valve. I have had it installed, then uninstalled and machined a little bit---repeat---repeat---repeat. The issue is that there is very little difference between the rocker arm position when it is "up" on the cam and "down" off the cam. Literally, thousandths of an inch. At the moment, it is about 0.030" too short, and will happily swing under the rocker arm no matter what position the cam is, either "up" or "down". Tomorrow I will take my trusty mig welder and build the short end up, then reshape and file it and hopefully get it to swing under the rocker only when it is "up" on the cam.

Dethrow55--I was pleased to hear from you this morning, and I thought "Wow--El Paso". Which of course made me think of the old song by Marty Robbins. Then this afternoon we heard about the terrible mass shooting there. I hope you and yours are all right.---Brian

Not a lot of shop time today, but some---This cute little devil is the lockout lever. This is the fun (mystery)part of every hit and miss engine I have ever built, and to a large extent this part determines how well the engine "hits" and "misses". As you can see, I've added a 0.070" thick boss to one side. This is to move the lever out farther away from the rocker arm pivot--the farther it is from the rocker arm pivot, the more movement there is in the rocker arm. And it is the difference between "up on cam" and "not up on cam" that I have to take advantage of. At the extreme right end, you will see that the lever is notched for clearance. When the engine is running slowly, the governor weights are in a position that lets the end of the lockout lever set beside the rocker arm. When the engine fires and begins to run faster, the governor balls kick outward away from the camshaft, and cause the end of the lever to move in under the rocker arm, which prevents the rocker arm from moving through it's normal travel. This in turn prevents the exhaust valve from closing, and consequently the engine can make no compression--so---the engine slows down. As soon as it slows down enough, the governor balls move in closer to the camshaft and moves the lever out from under the rocker arm and lets it travel though it's full arc, and the engine fires again. Thus the "hit and miss" cycle. Tomorrow I have to add about 0.050" to the extreme right hand end (Thank God for mig welders) and do some more fitting.

Similar threads

- Replies

- 411

- Views

- 38K

- Replies

- 148

- Views

- 22K

- Replies

- 5

- Views

- 2K

- Replies

- 6

- Views

- 773