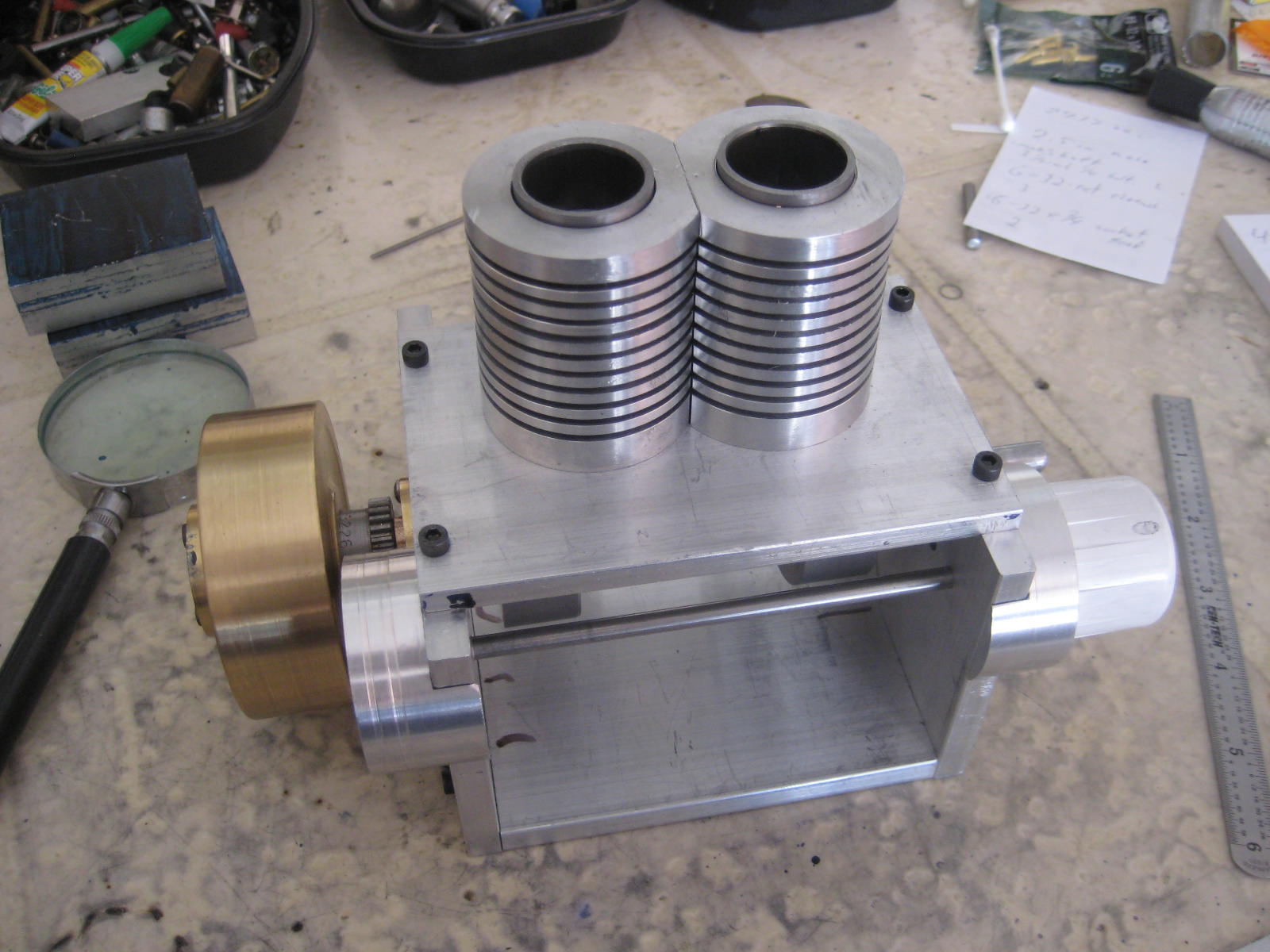

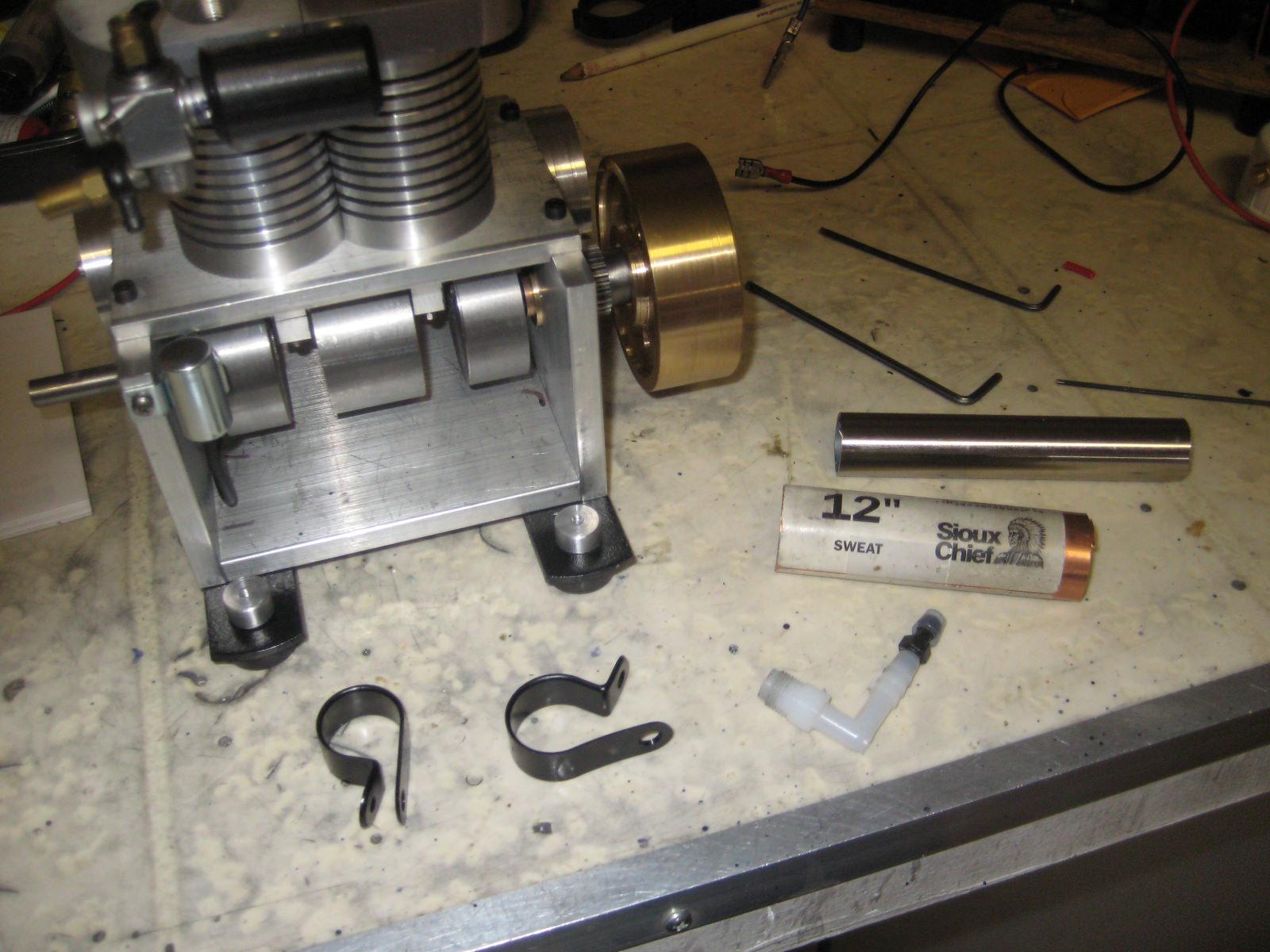

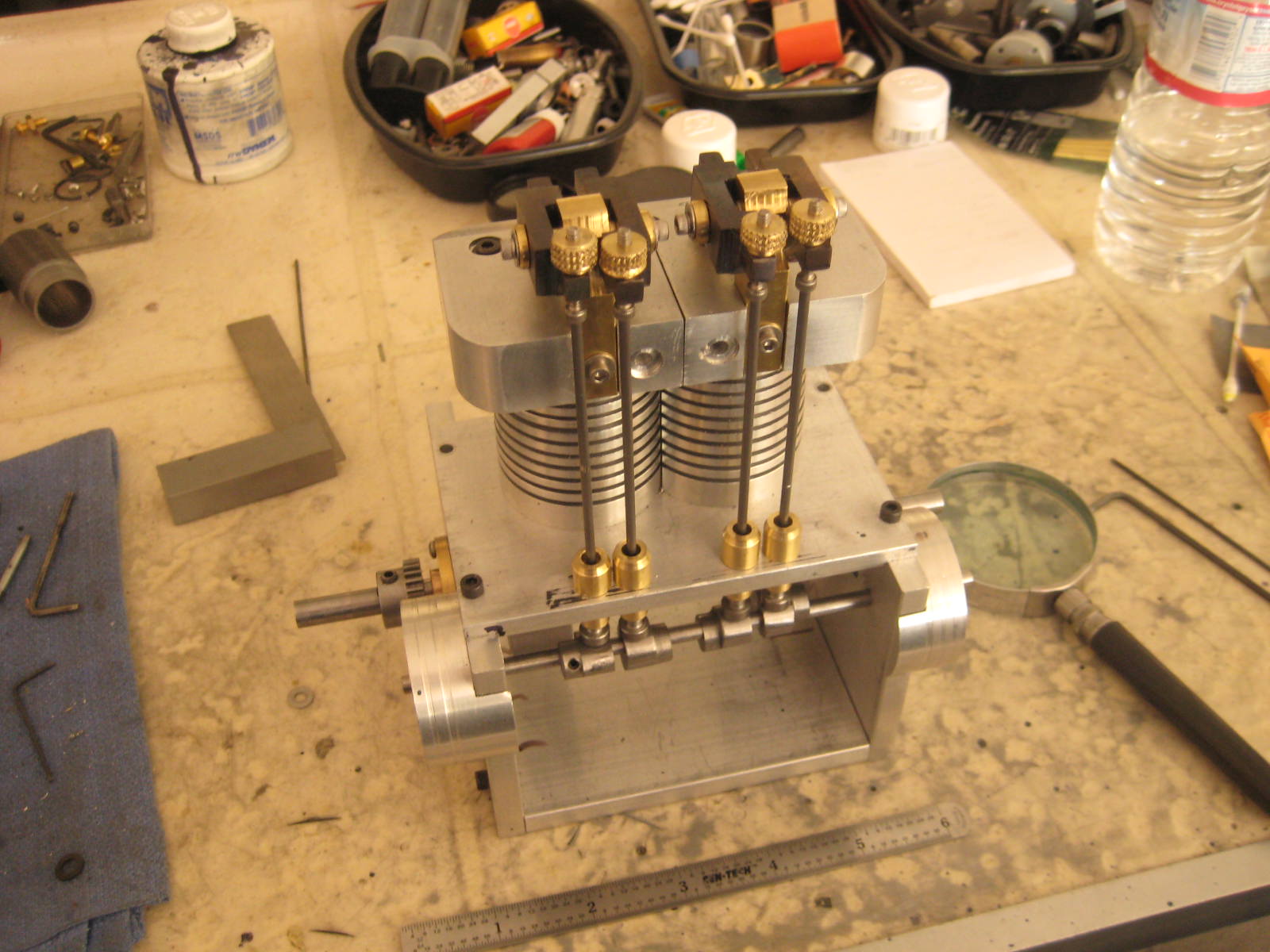

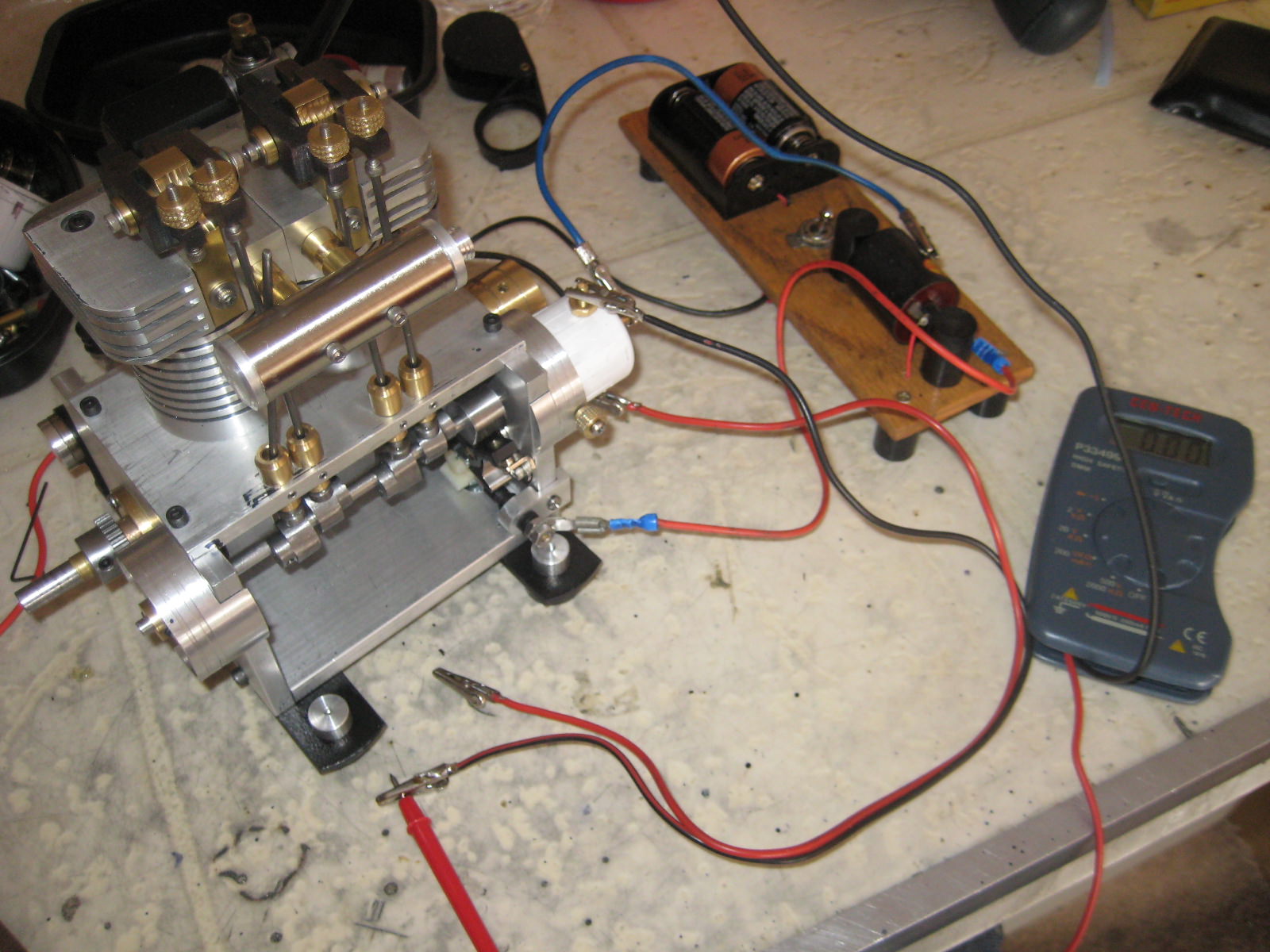

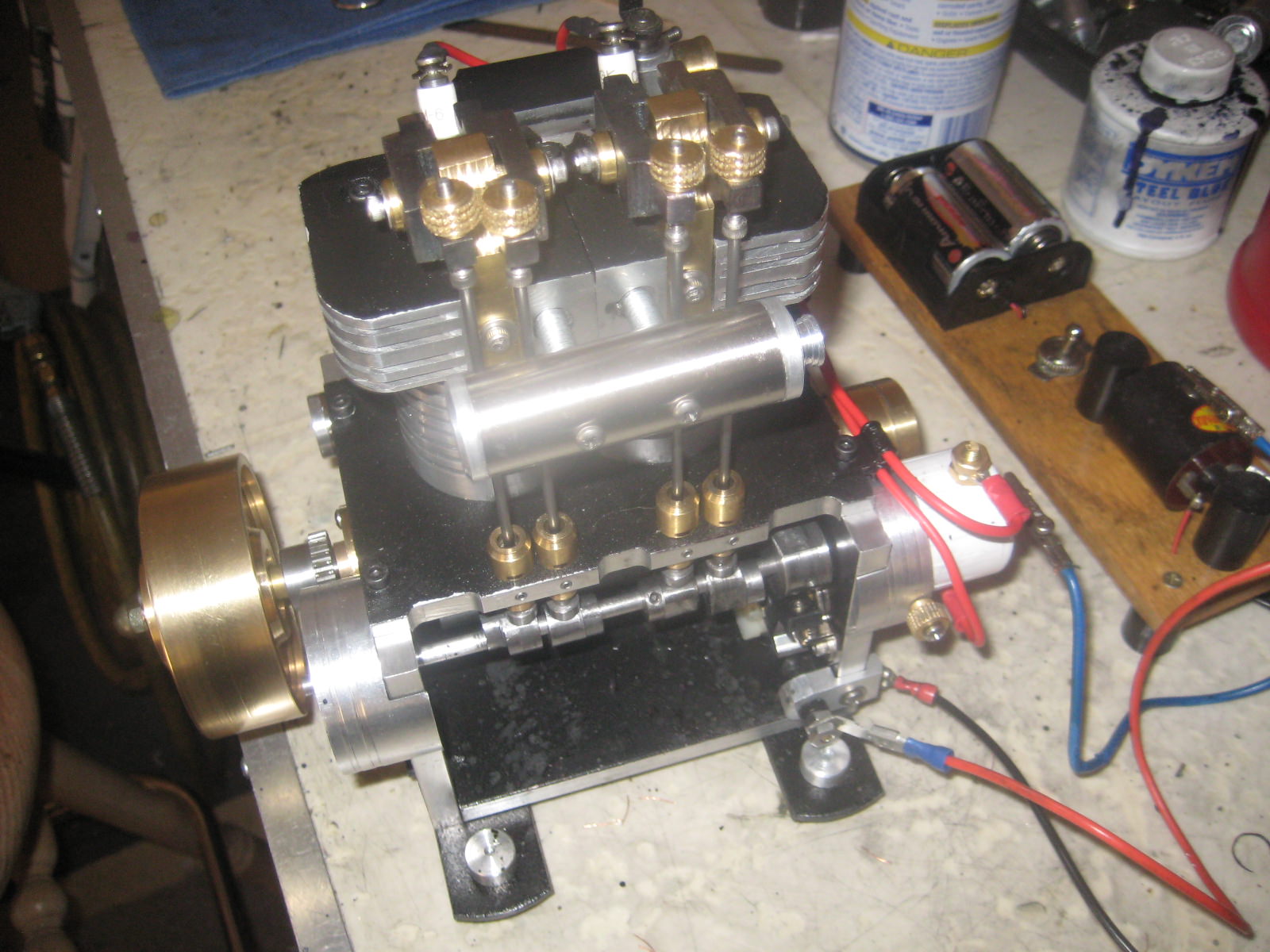

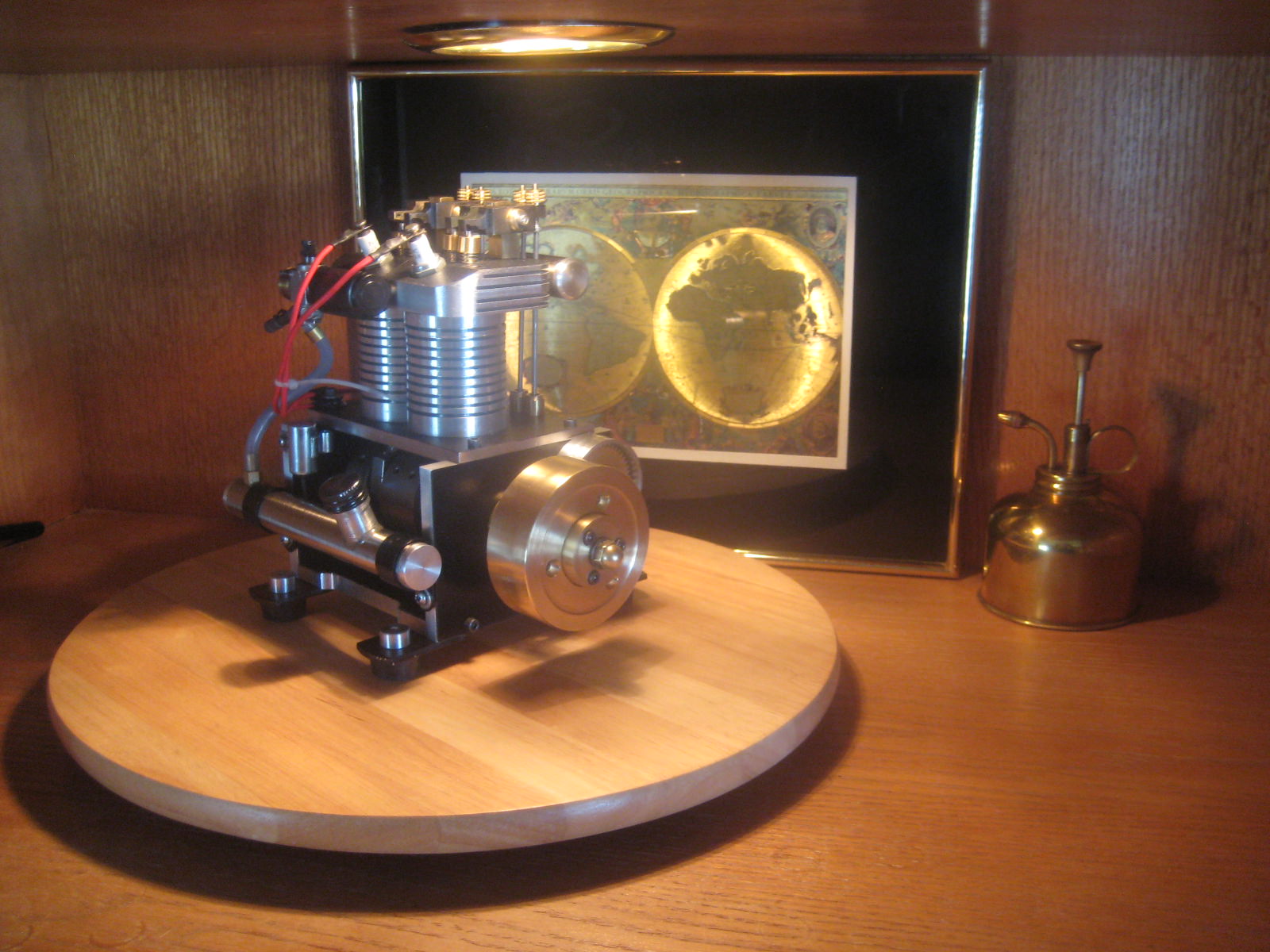

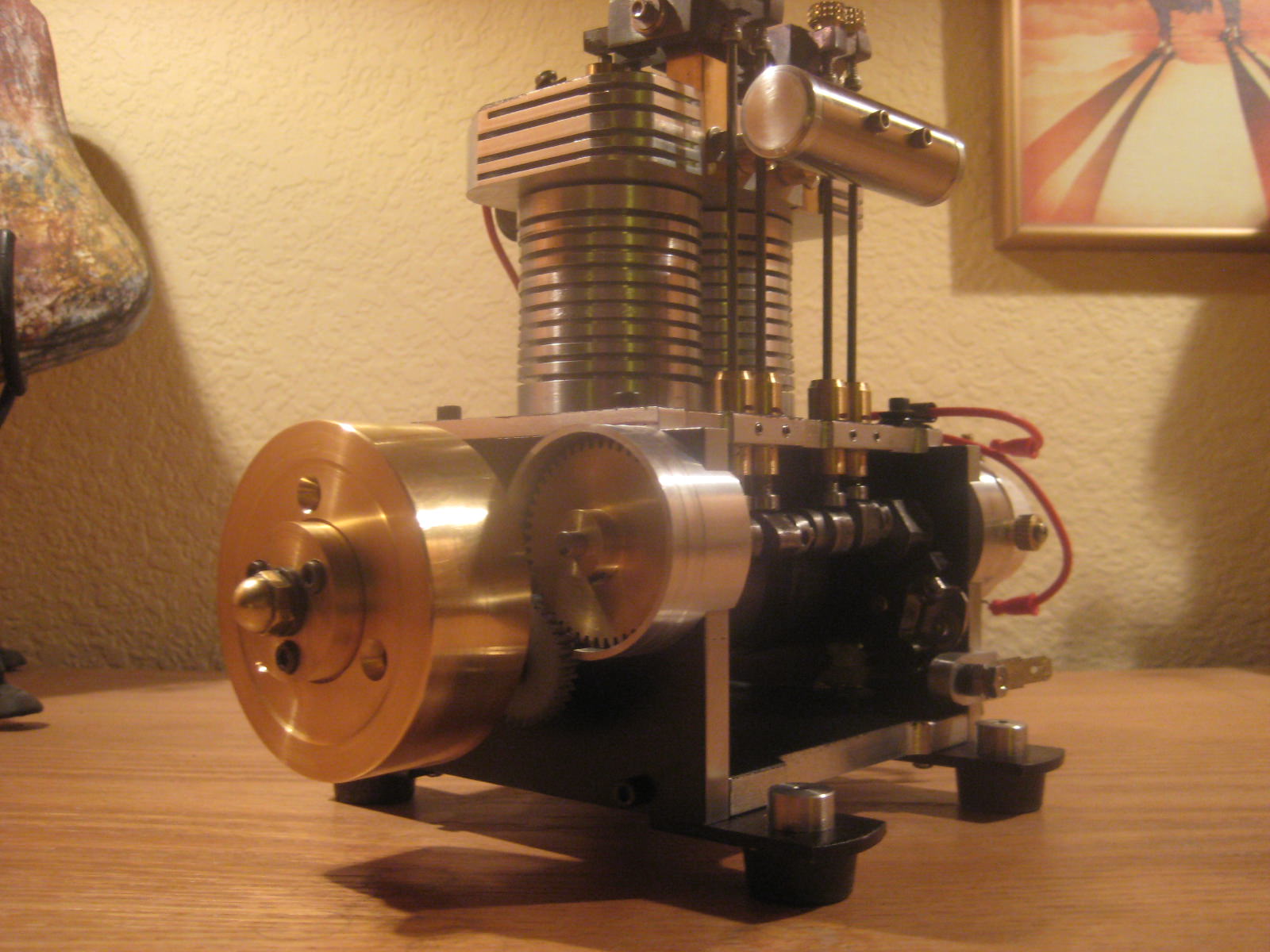

On my "Gemini" twin, I have a dedicated dual fire coil and 6 volt battery ignition mounted with the engine on a oak board. For "Overtime", I wanted a free standing engine and be able to use my traveling 3 volt battery pack & coil. To do so requires a distributor.

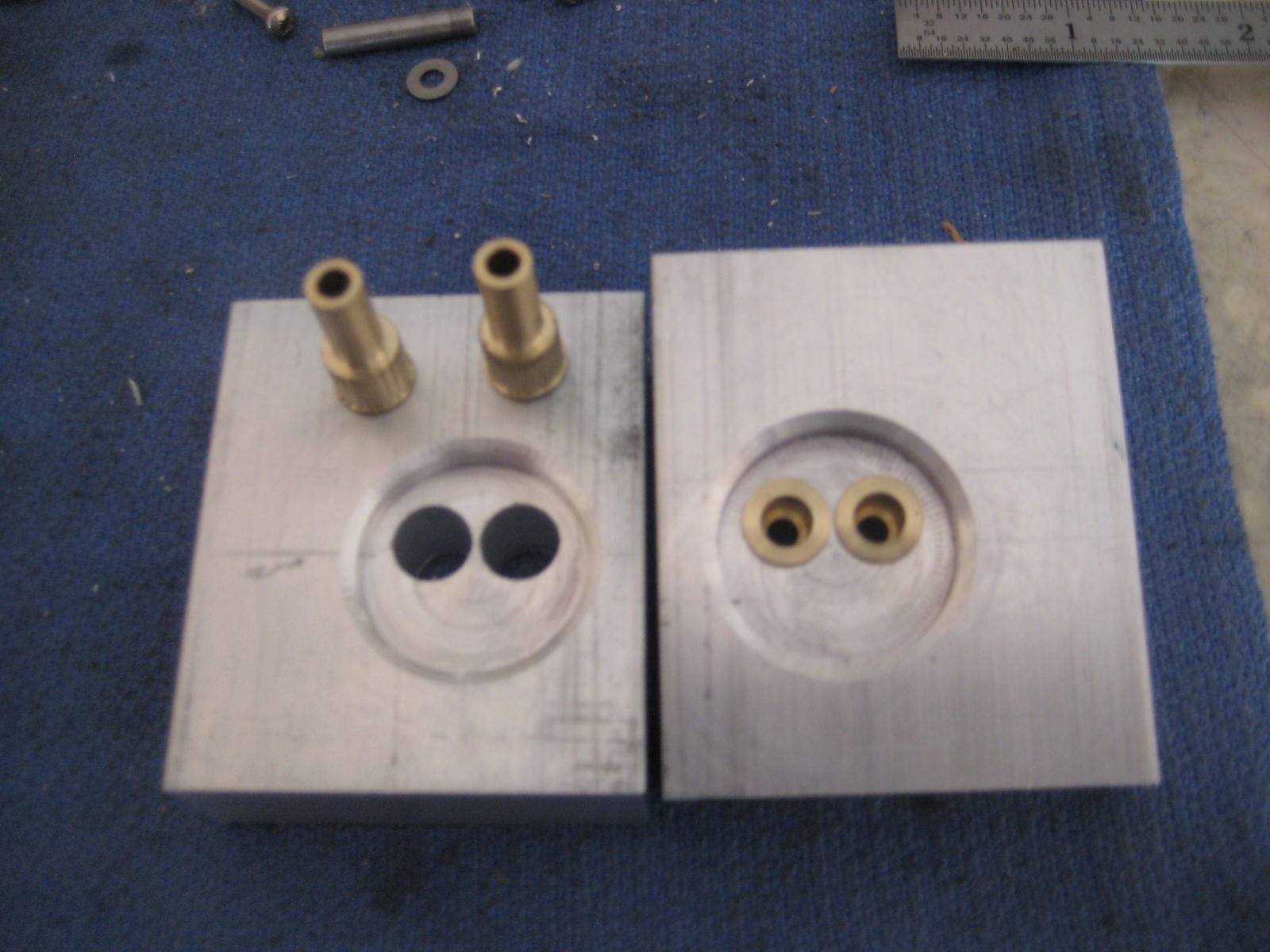

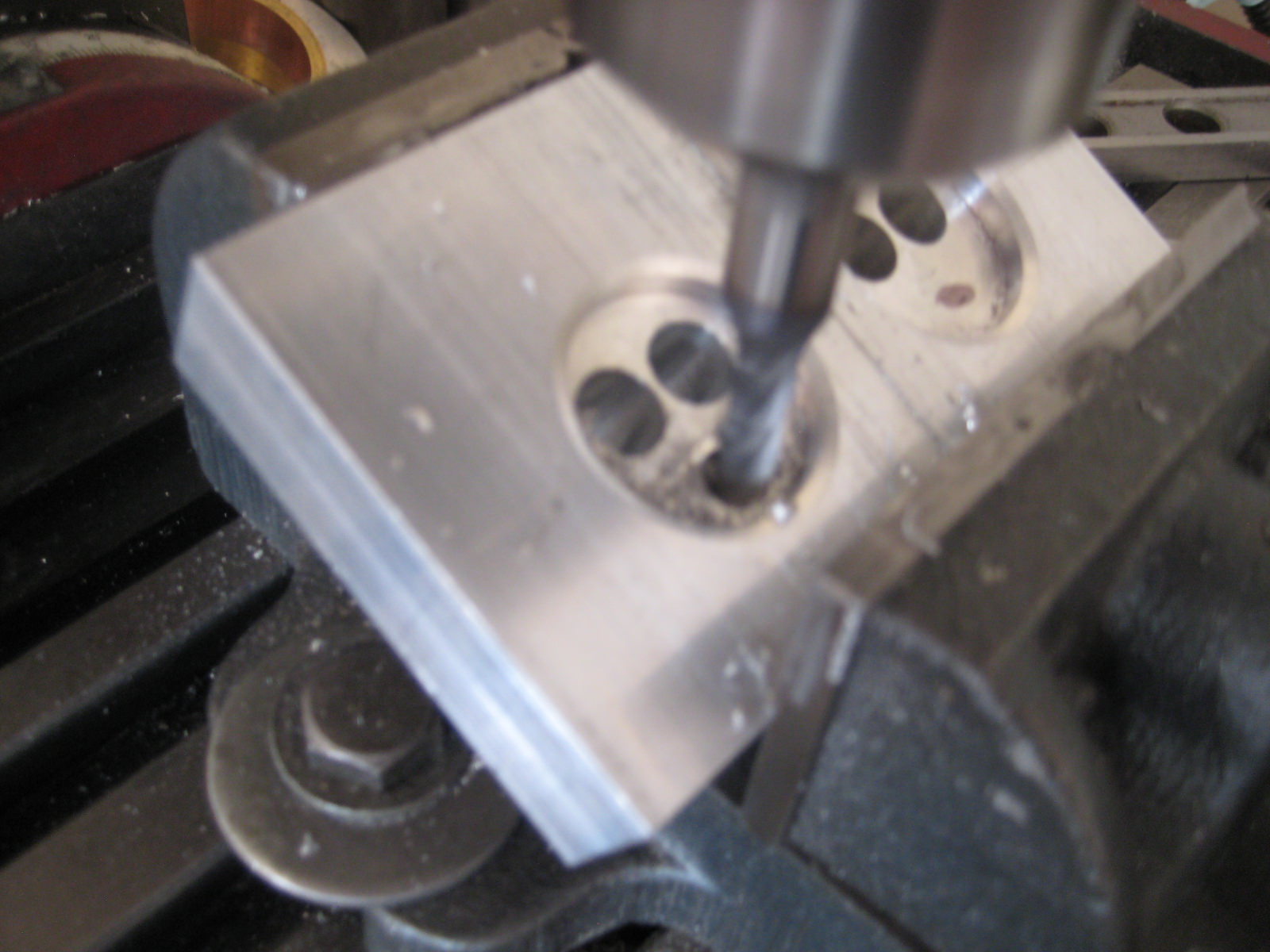

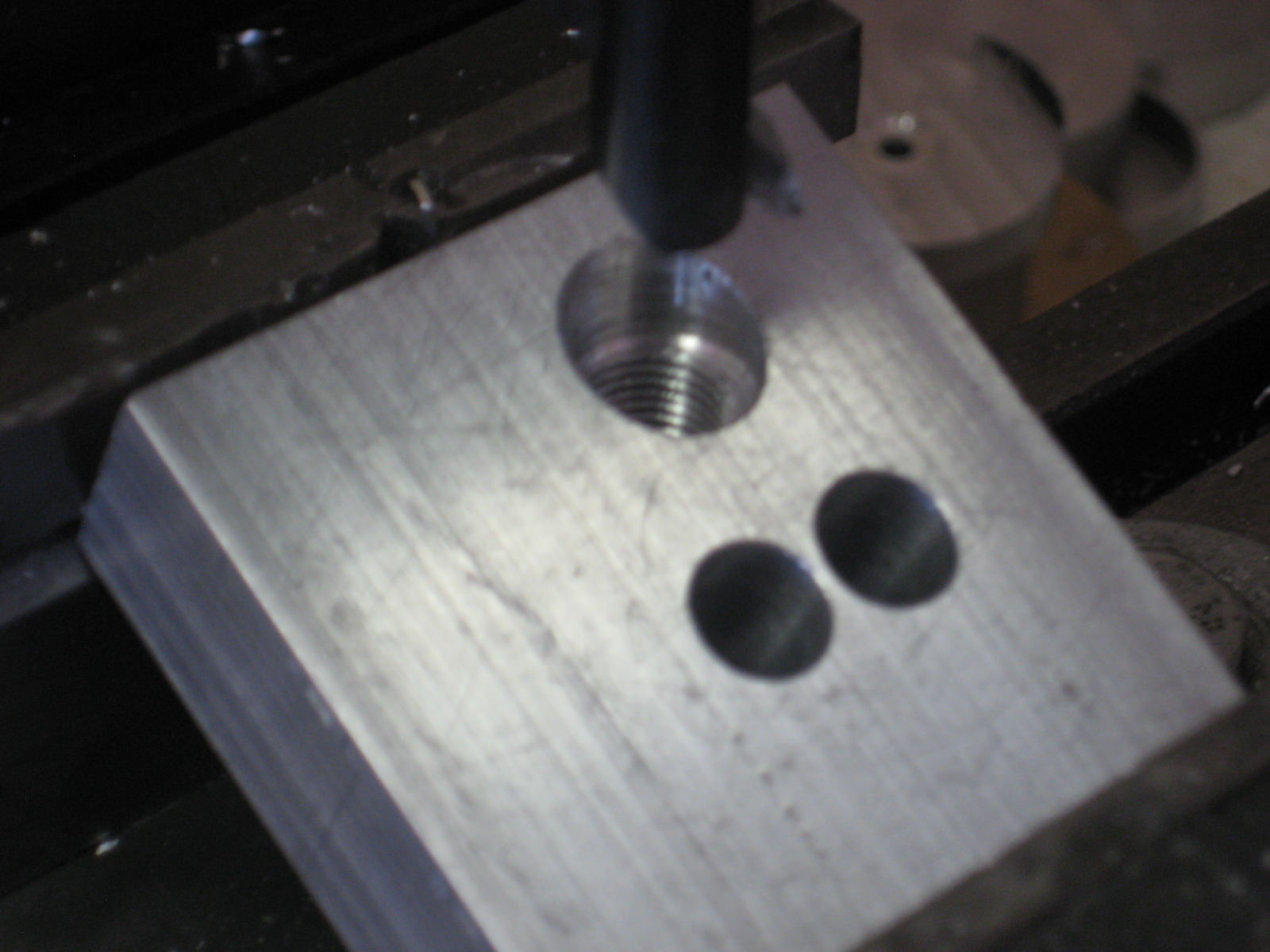

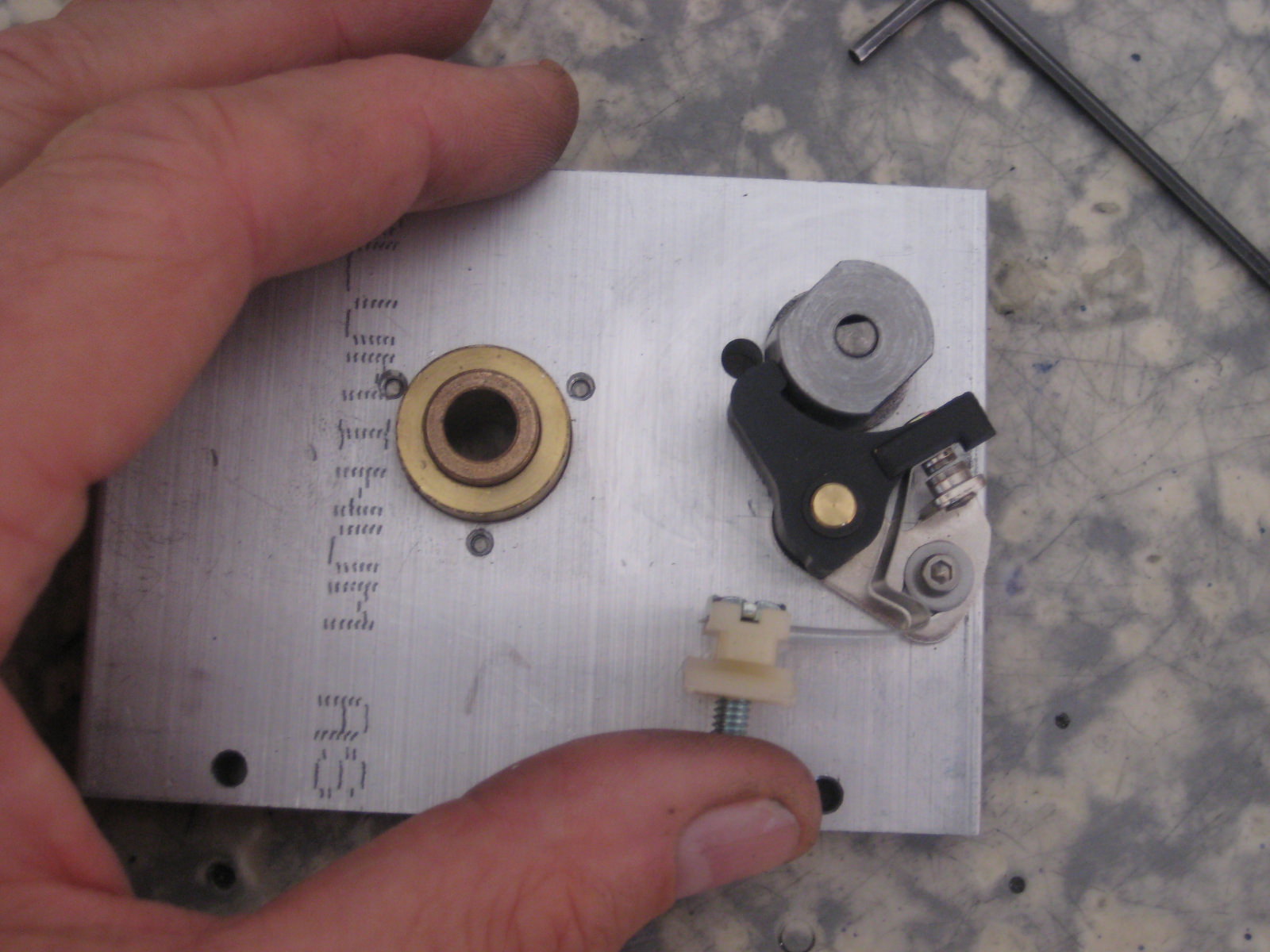

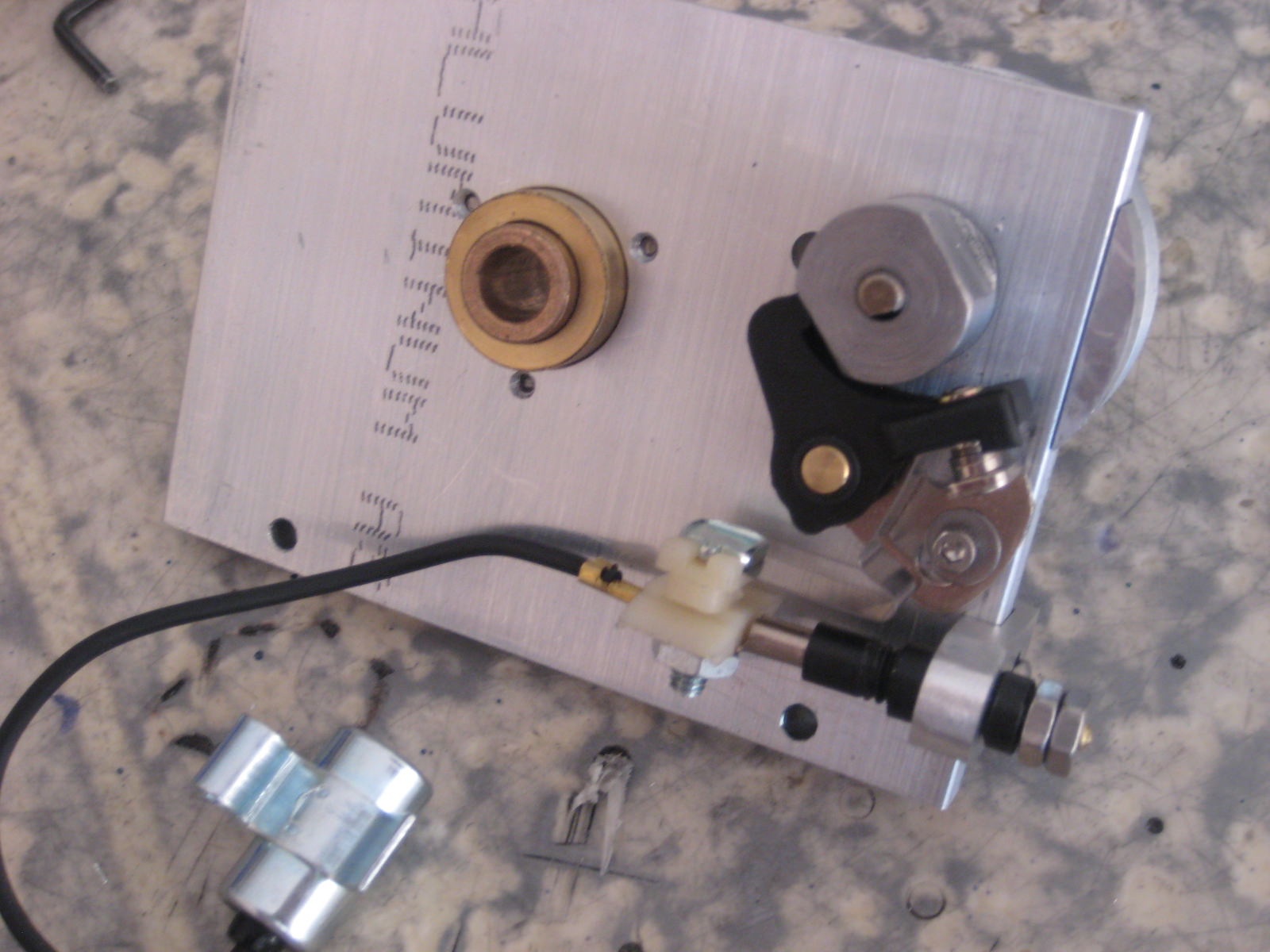

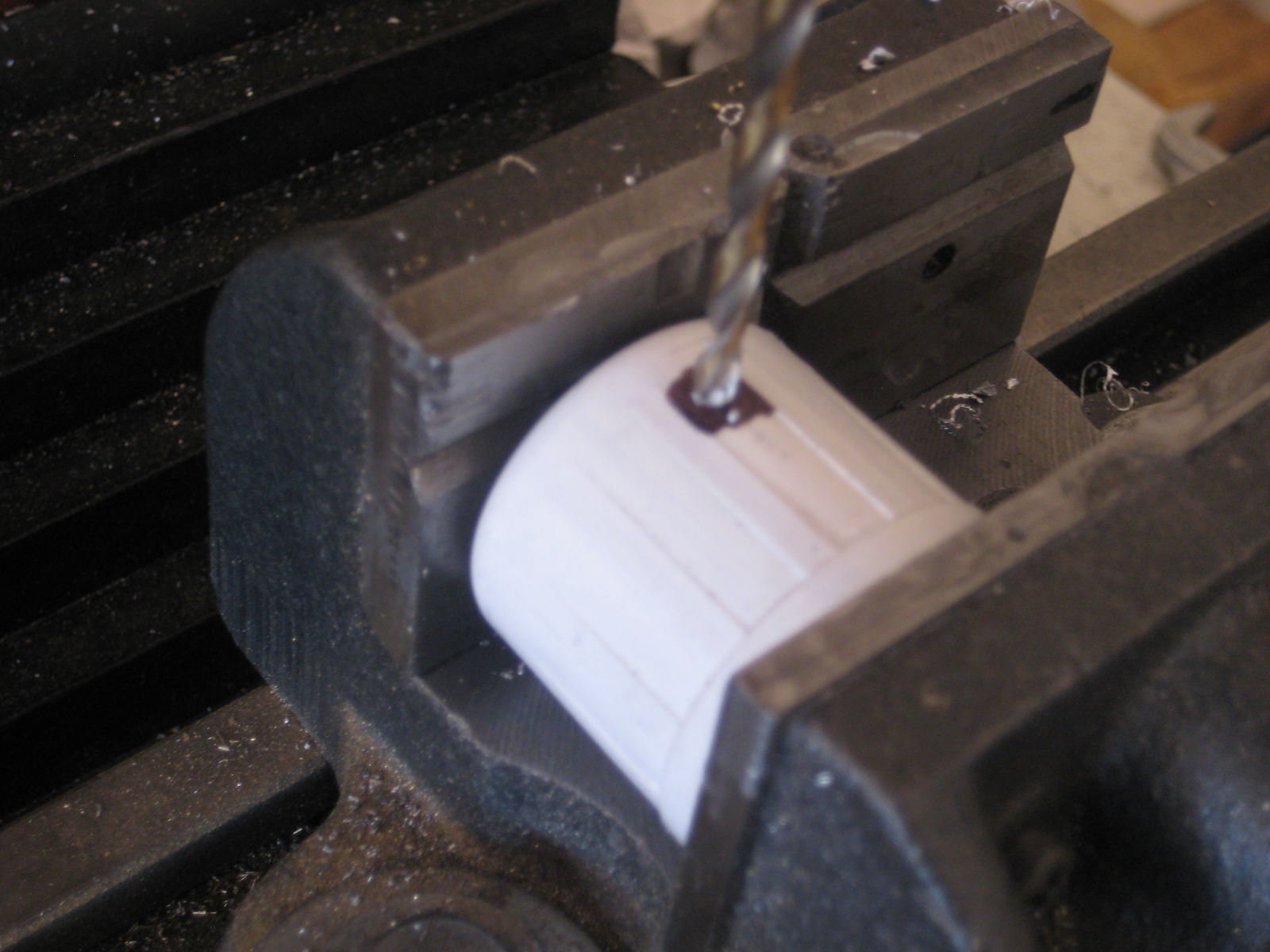

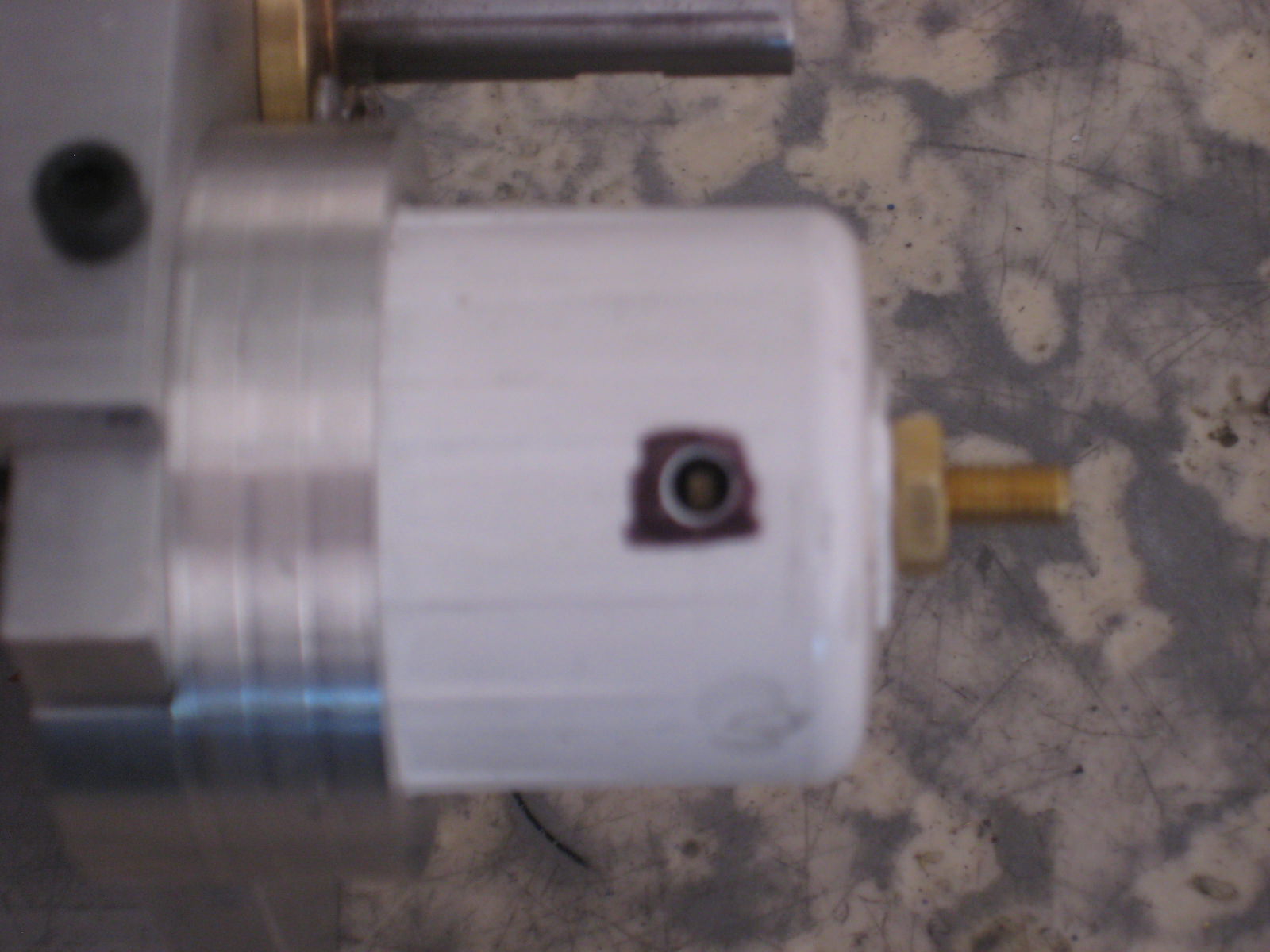

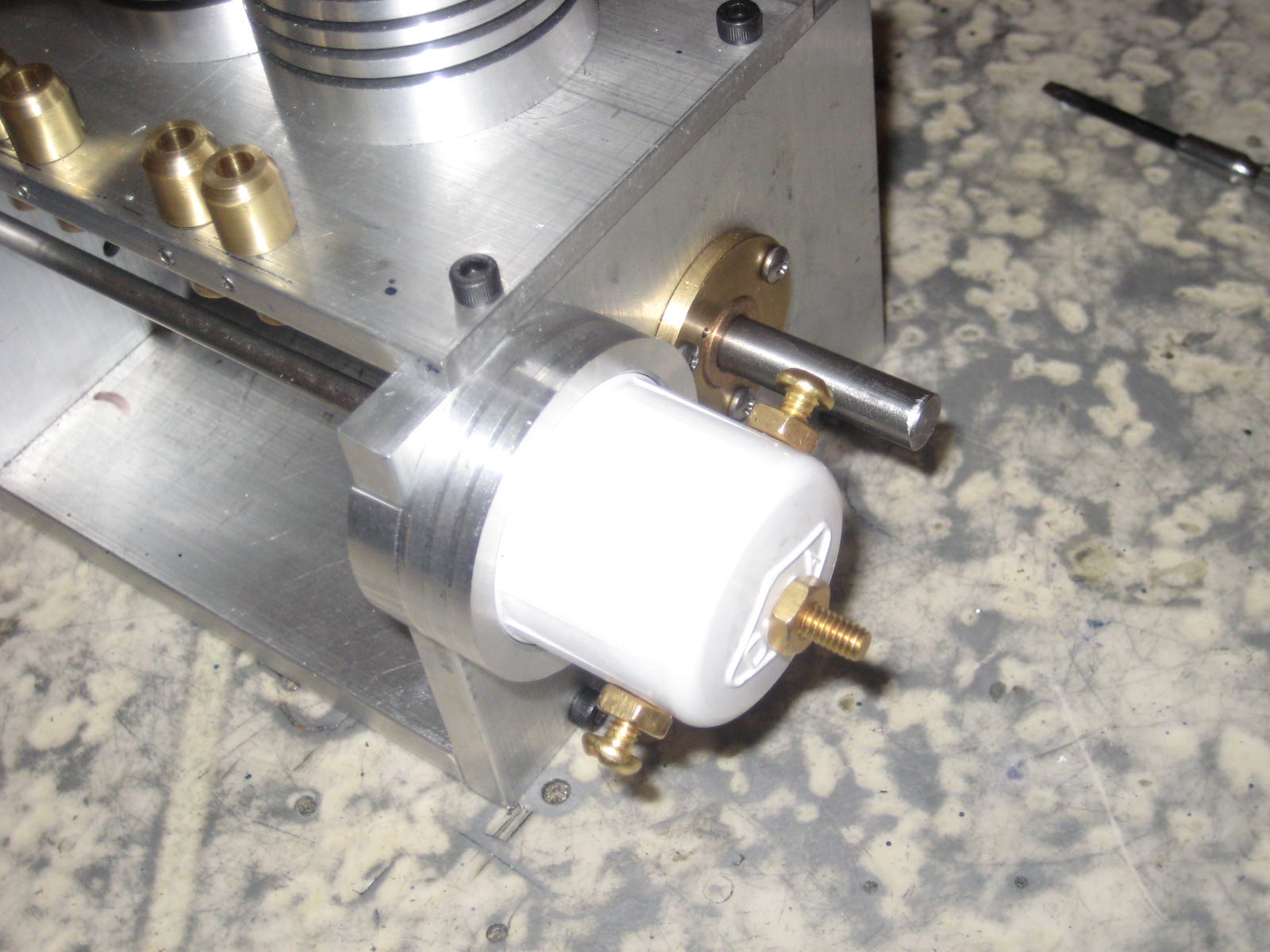

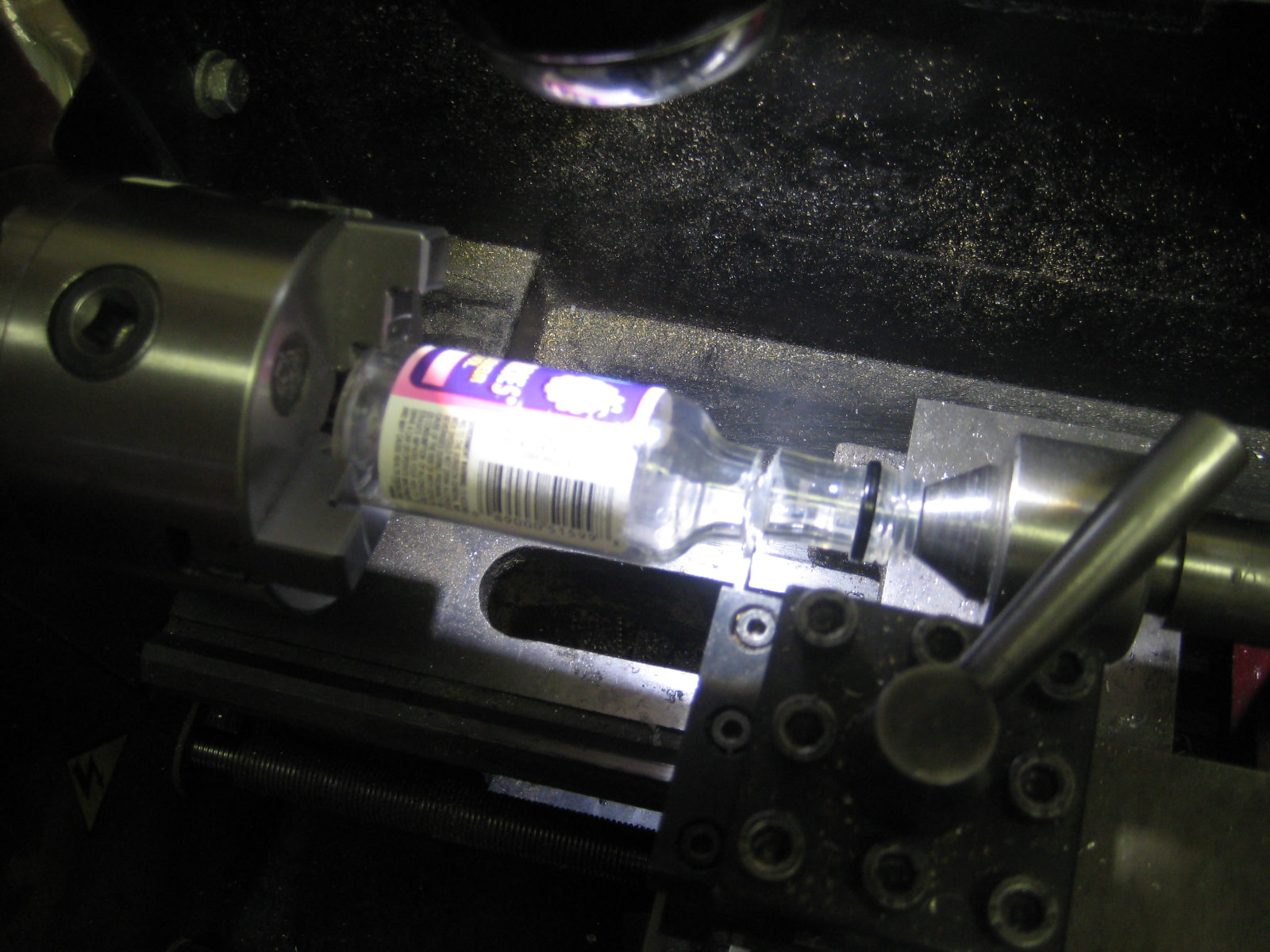

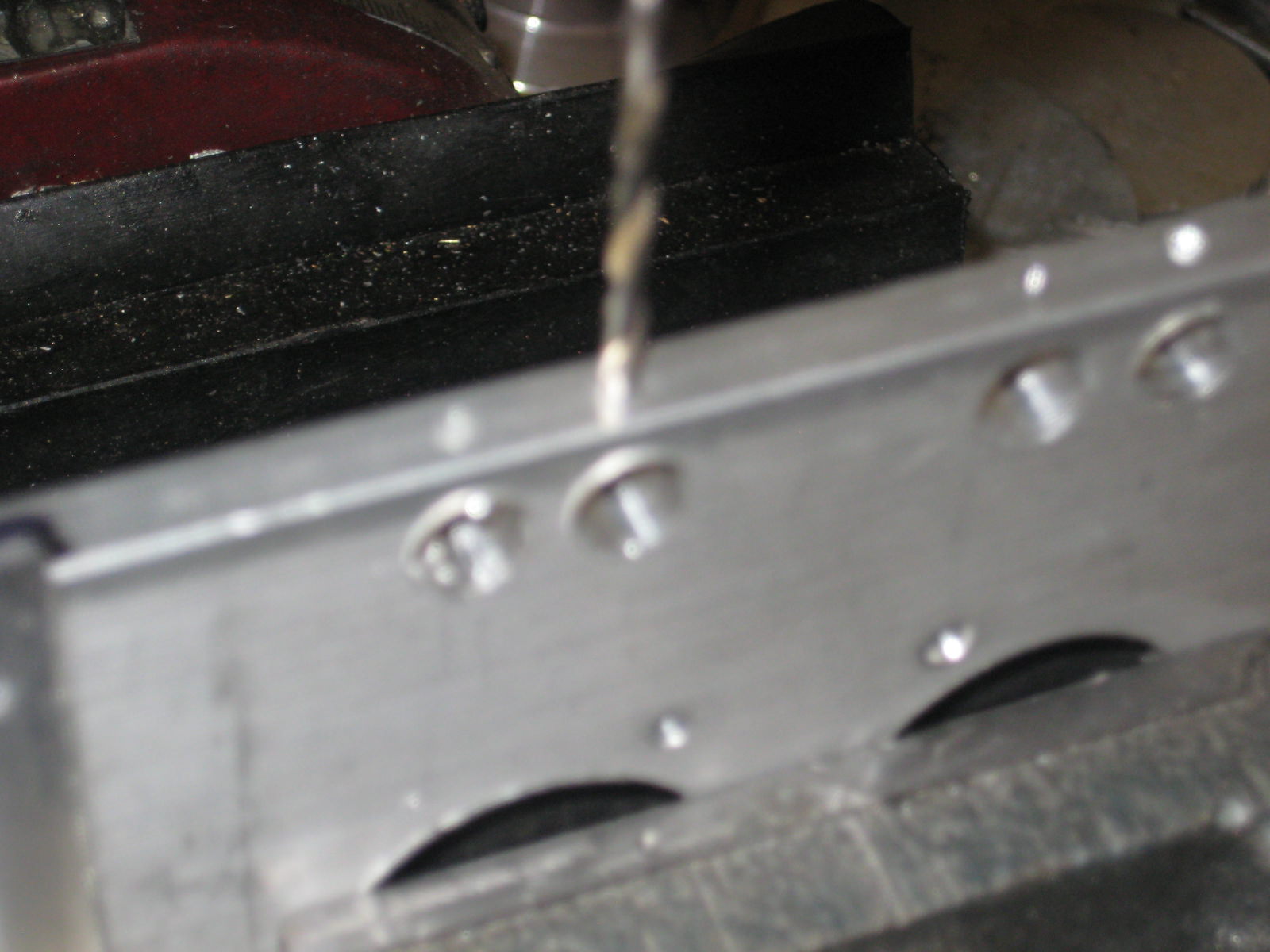

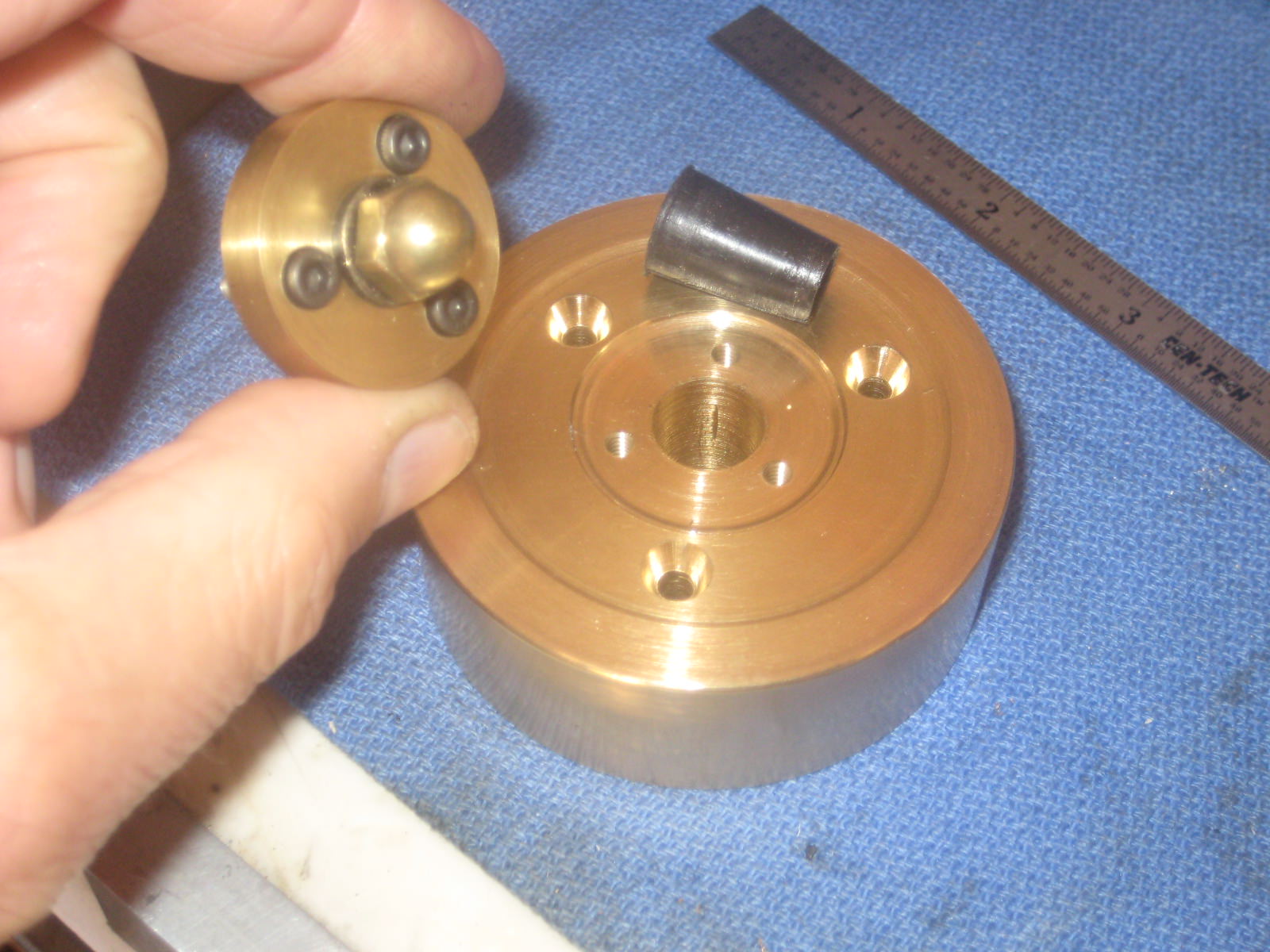

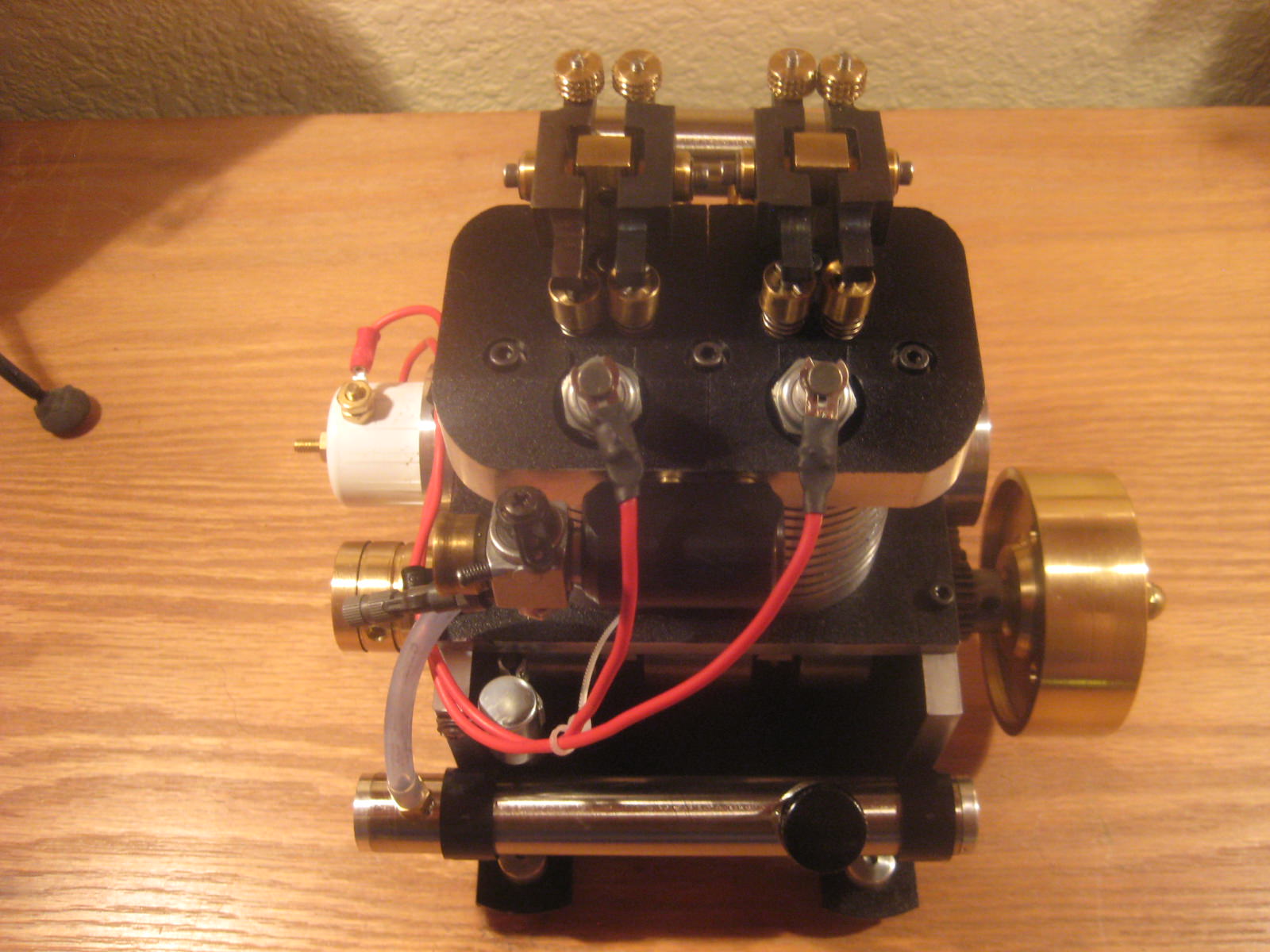

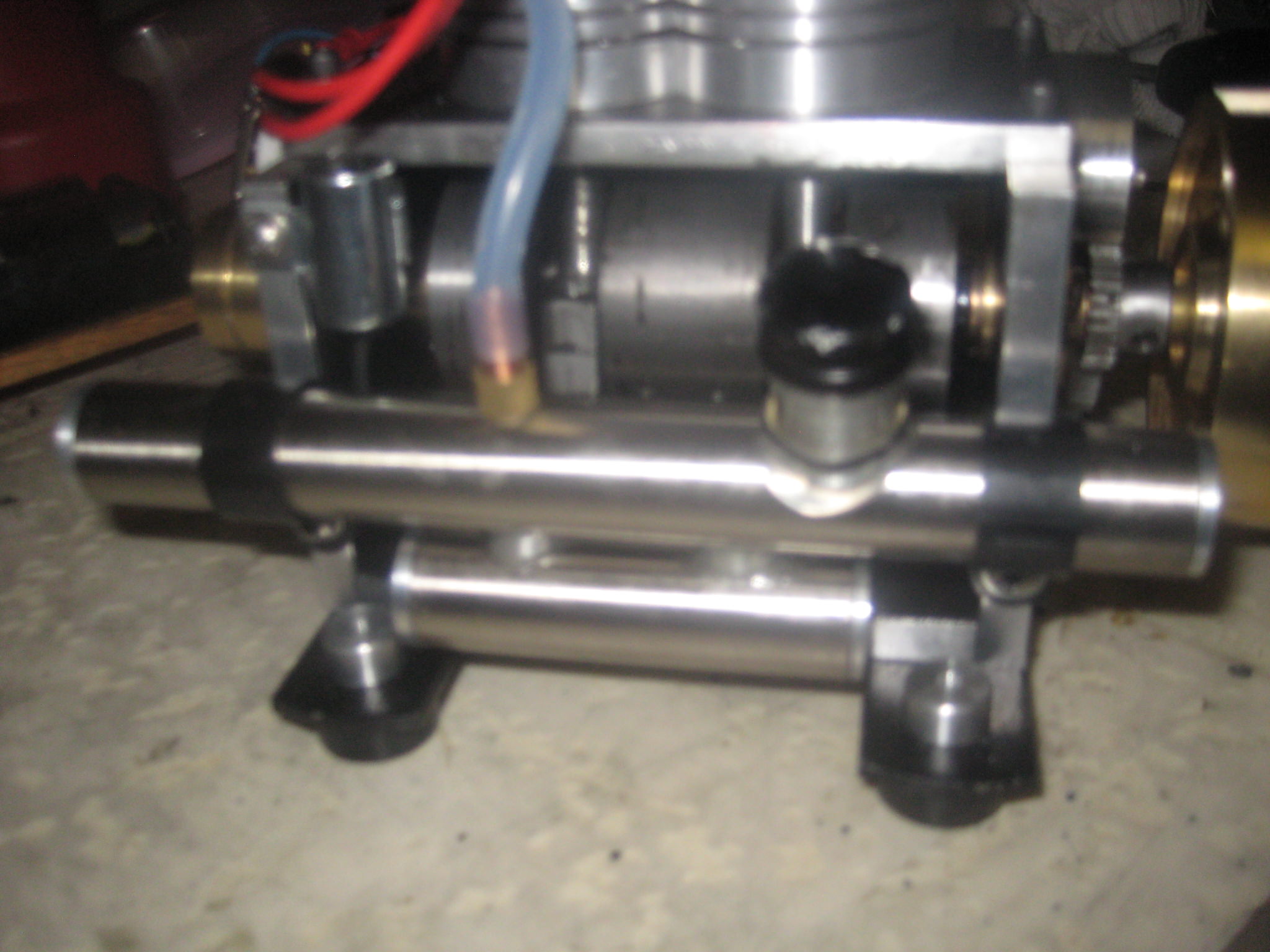

From Home Depot, I picked up both a 1-3/8in and 1 inch PVC end cap and bag of #8 brass machine screws & nuts. Used the 1 inch cap on the engine. Three drilled and taped holes located for coil and plug leads.

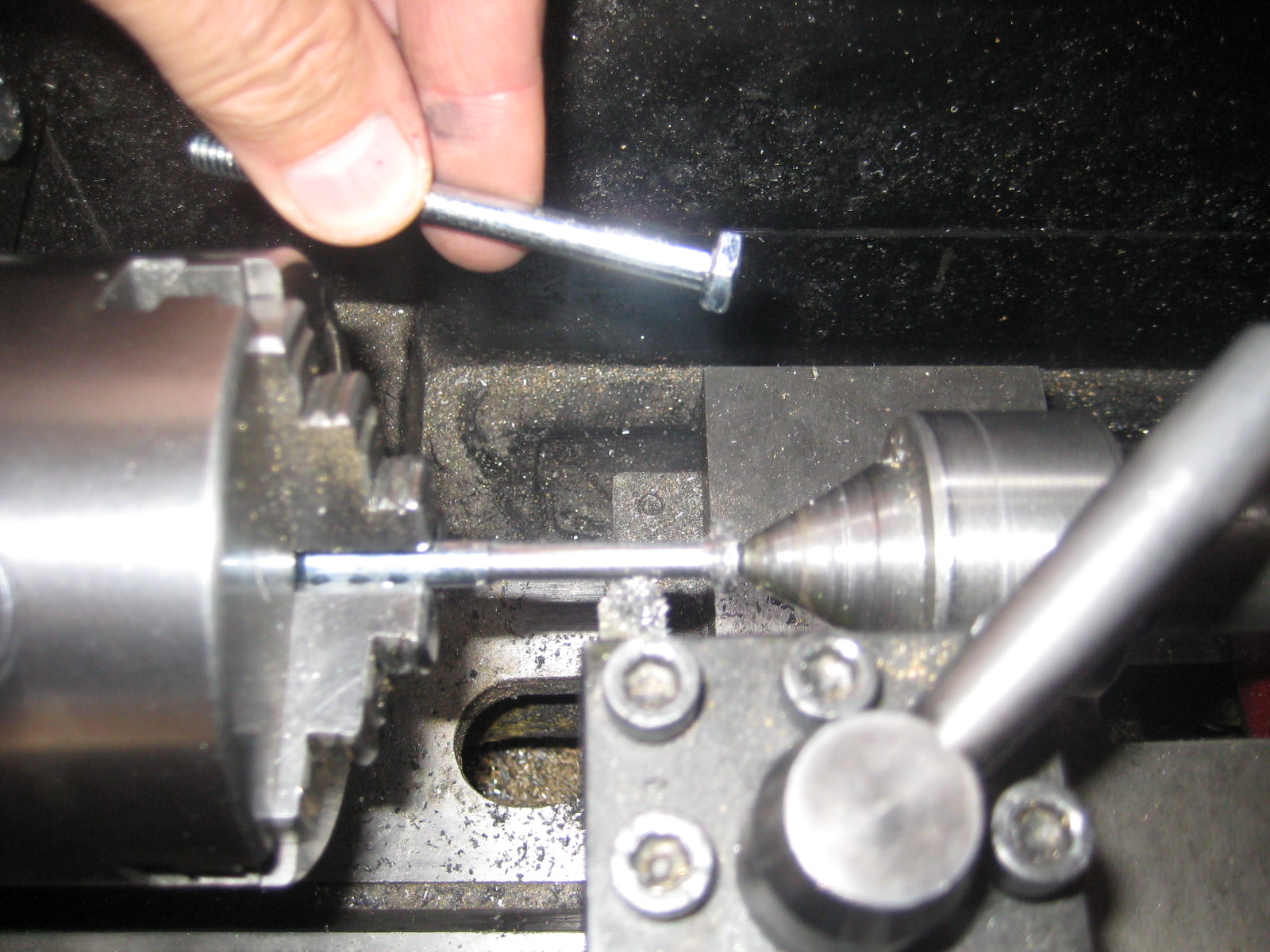

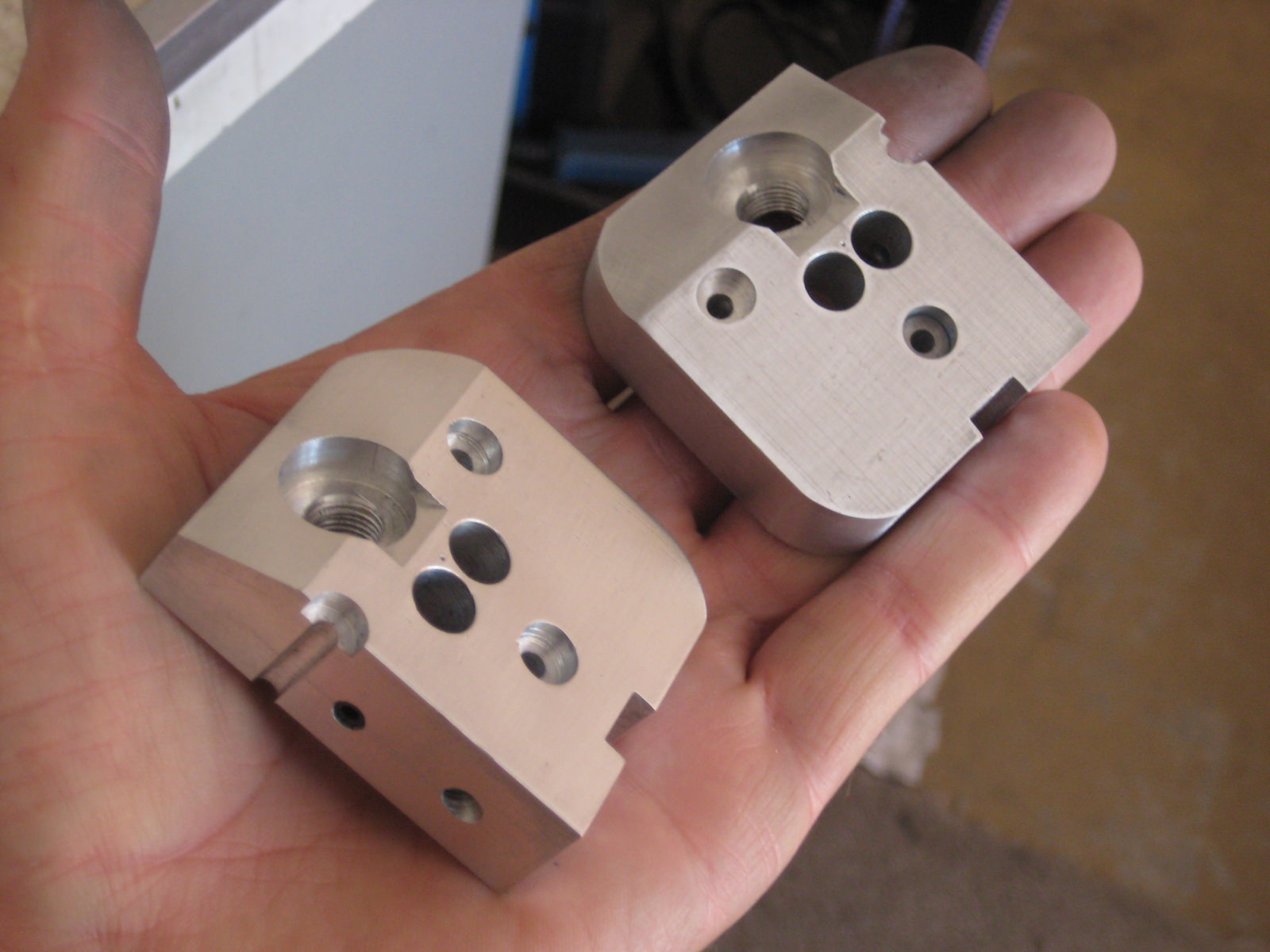

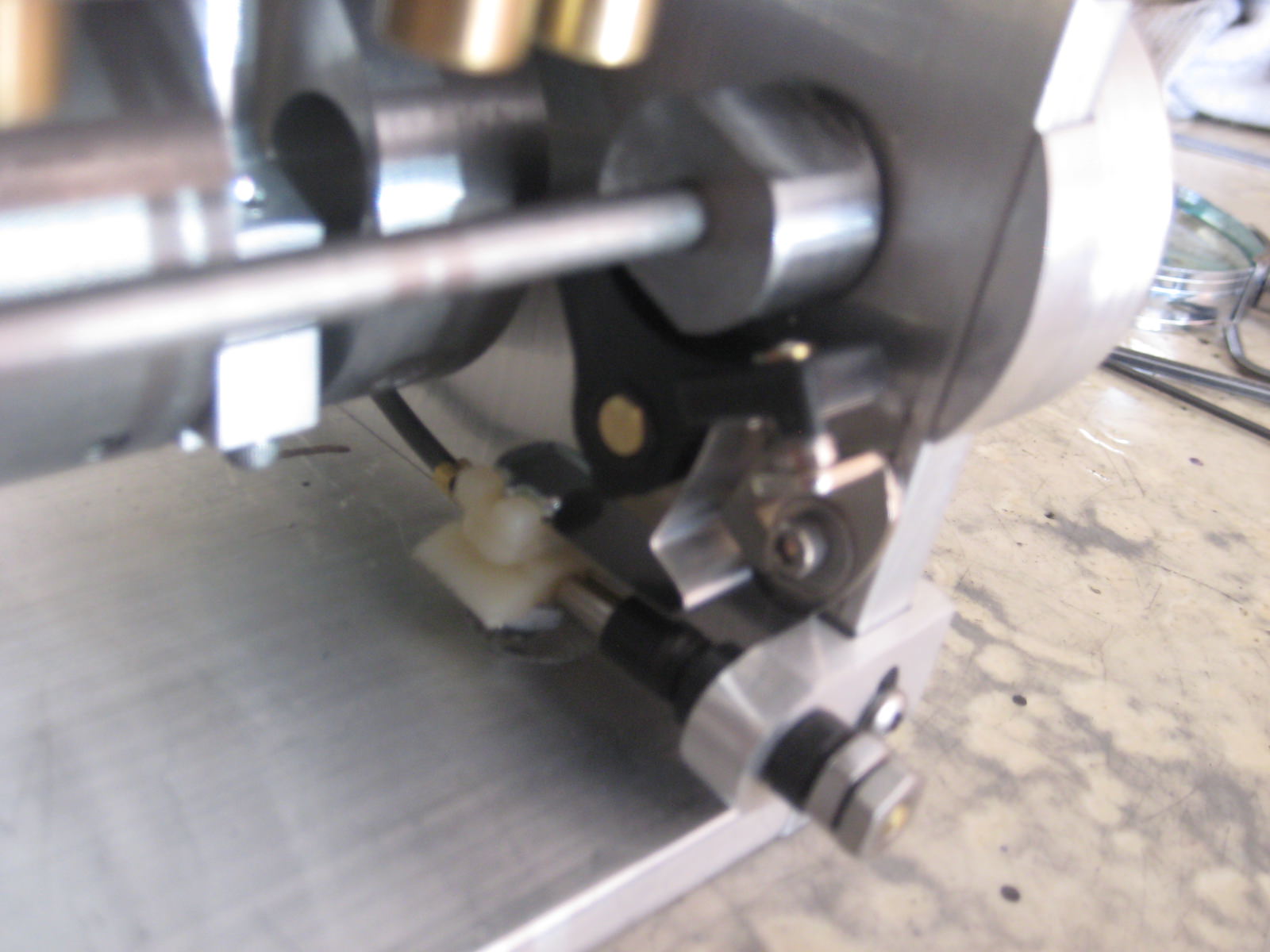

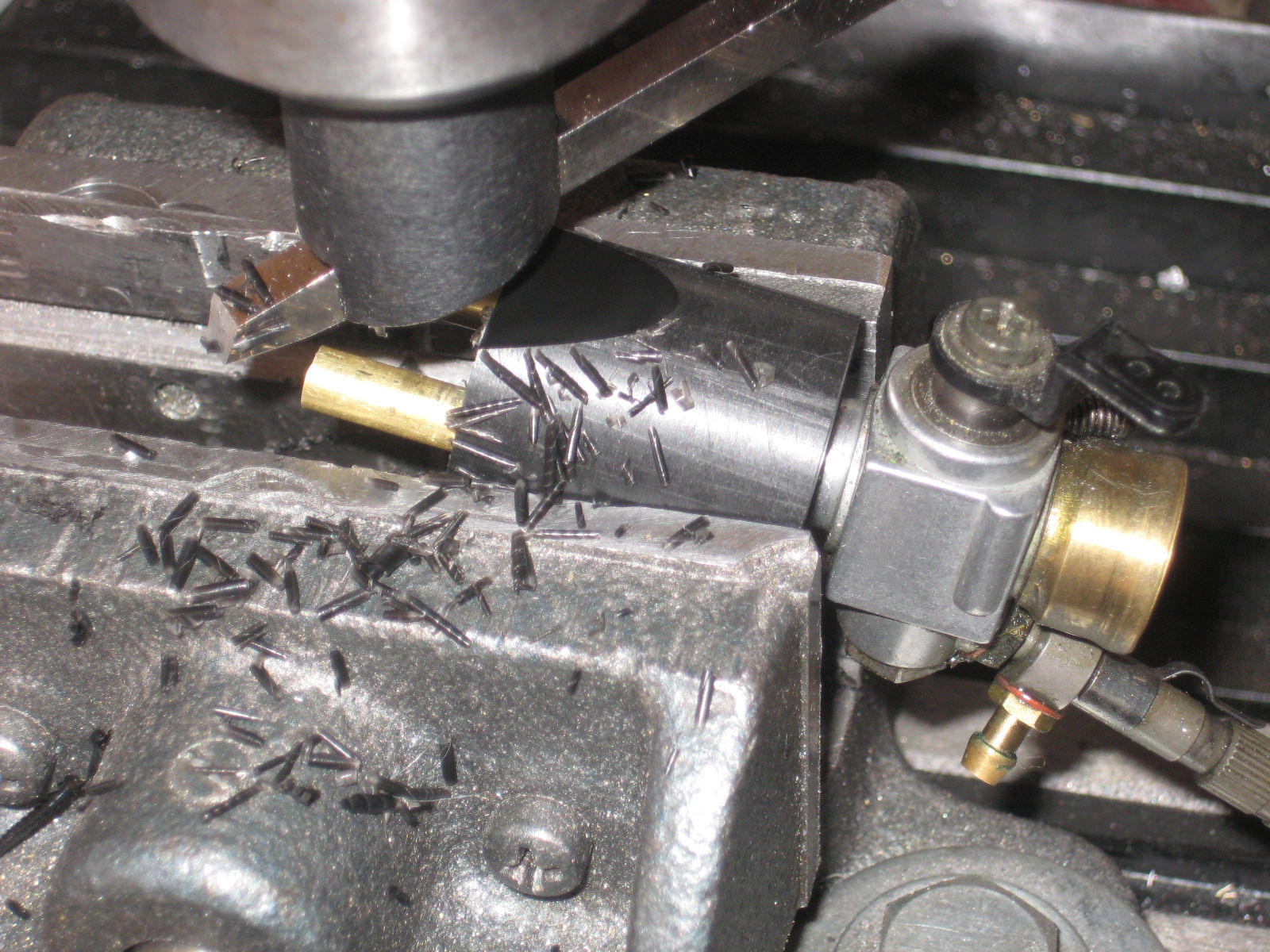

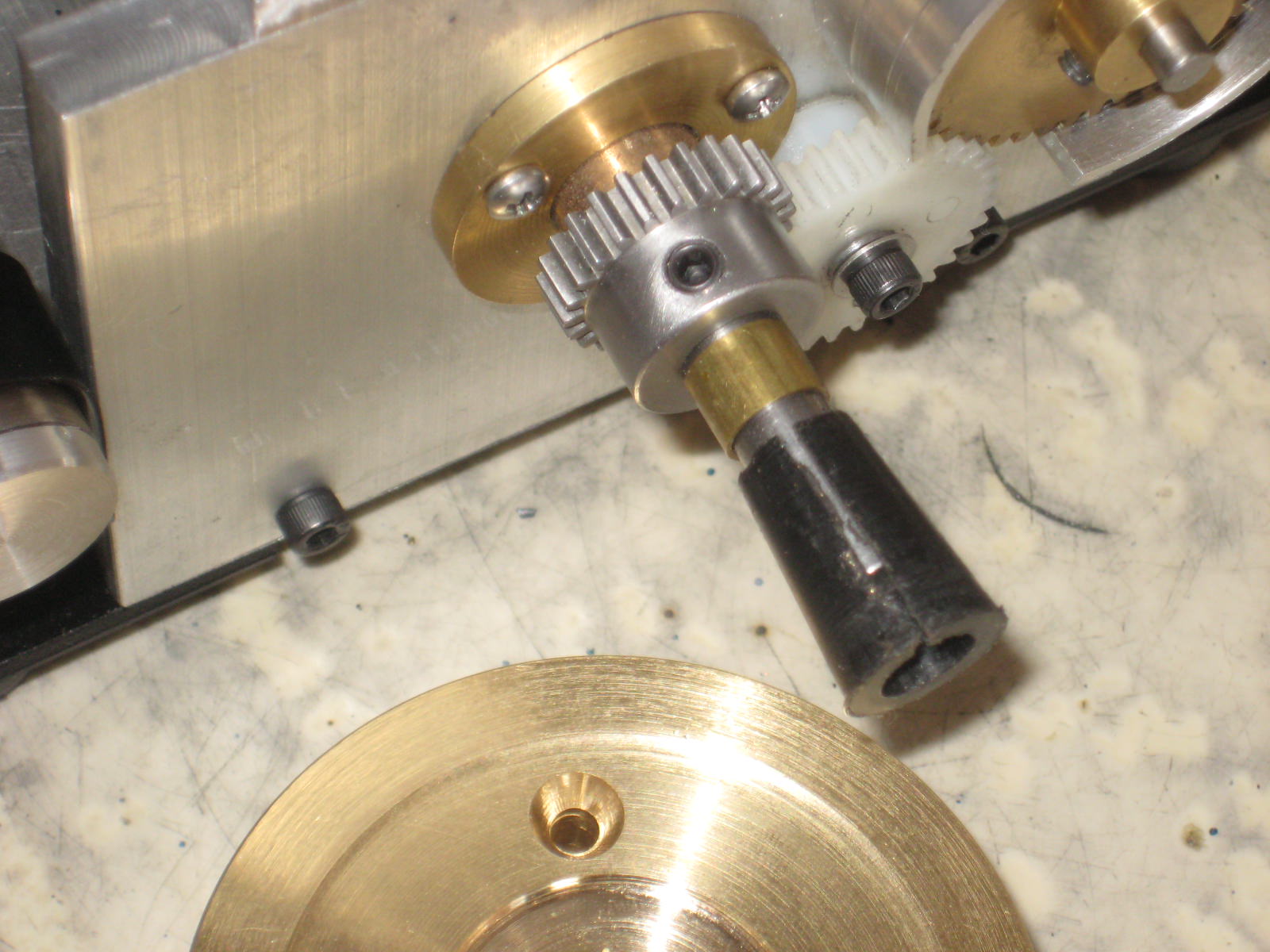

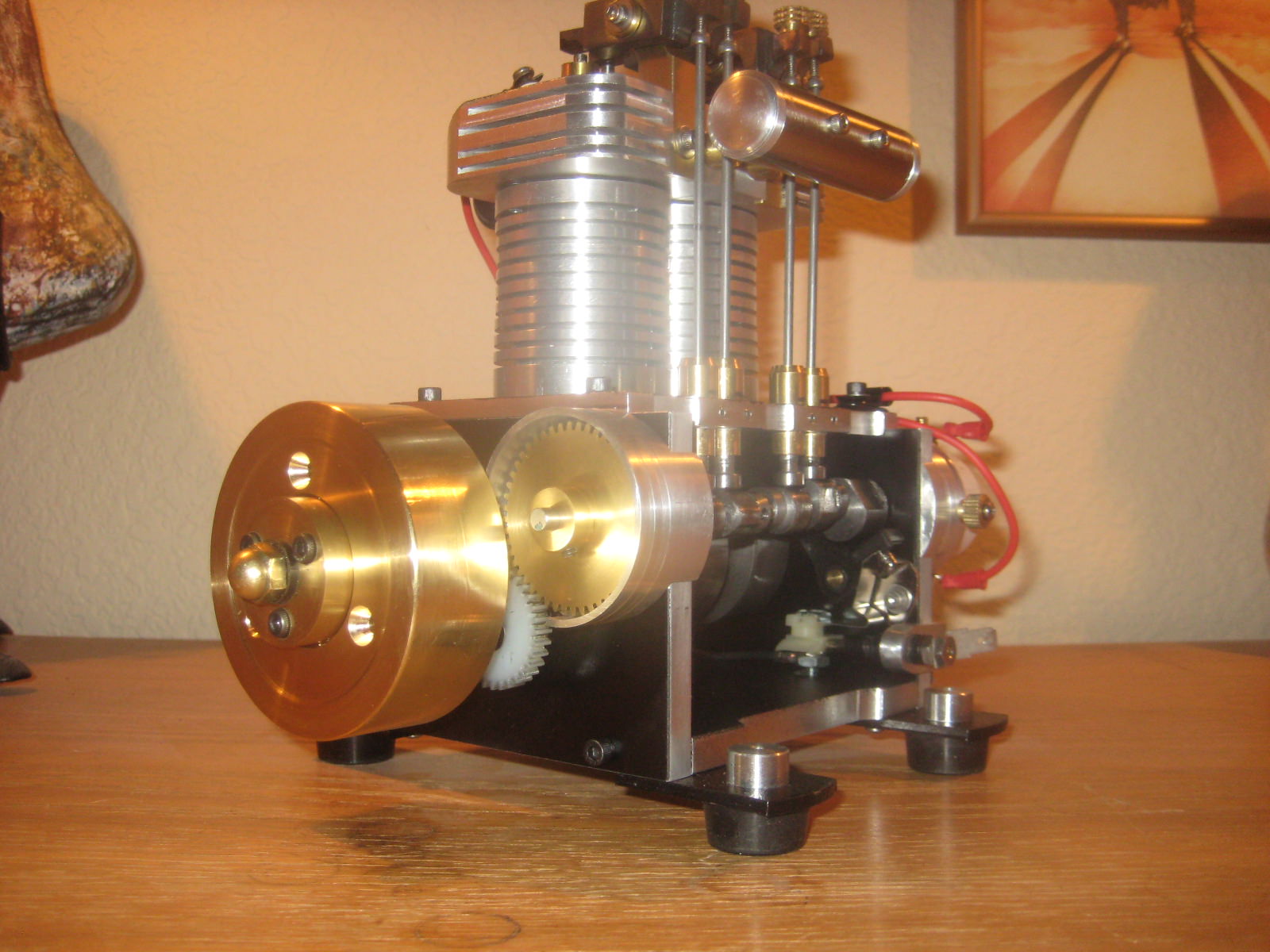

The rotor is Delrin with brass strap, stainless #4 screw. The coil screw is dished out to a ball & socket mate with the rotor screw head with a round nose tool bit on lathe. Threaded into cap from the inside, when placed over the distributor base it is threaded down till contact with the rotor screw and locked nutted in place.

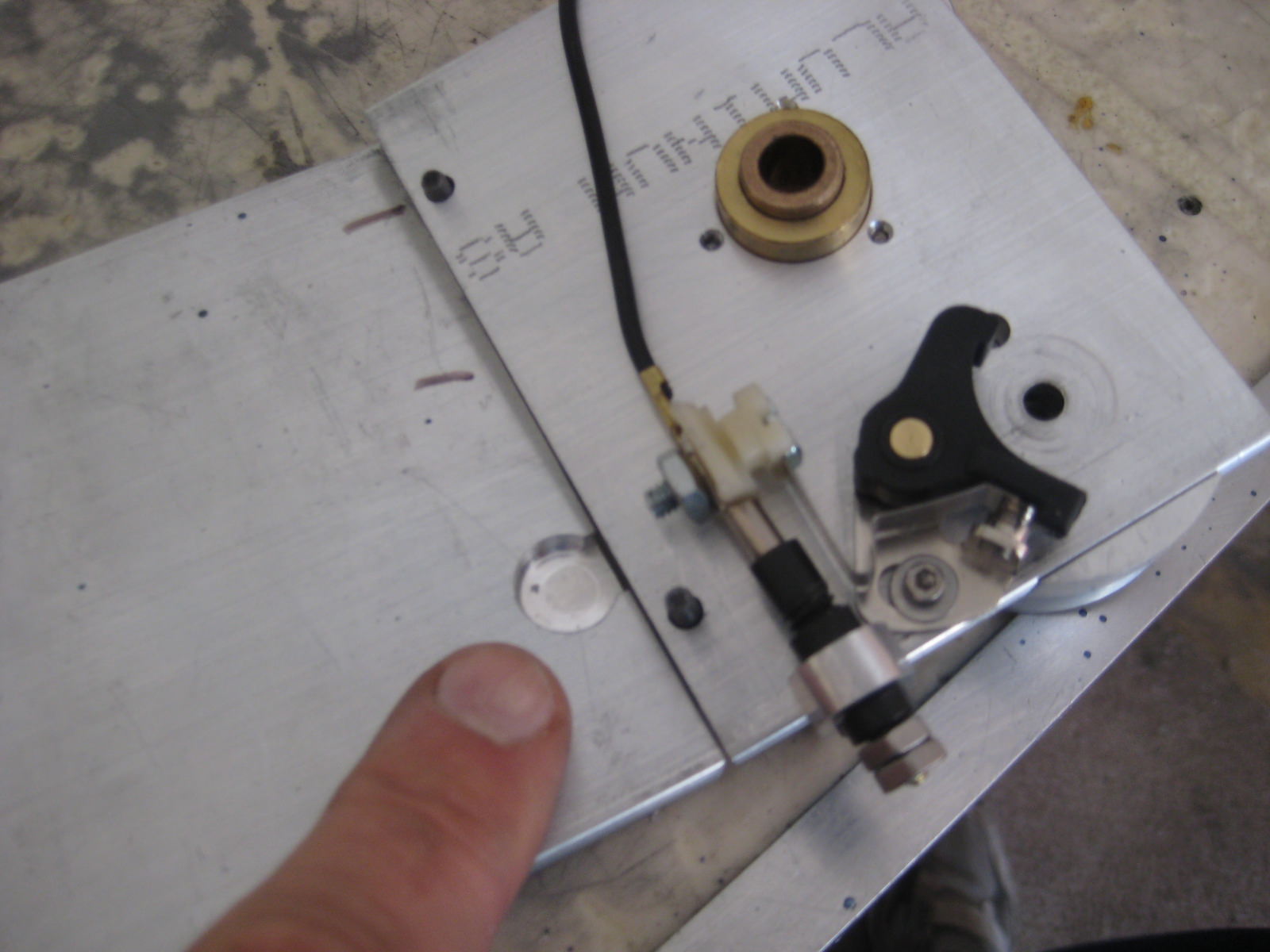

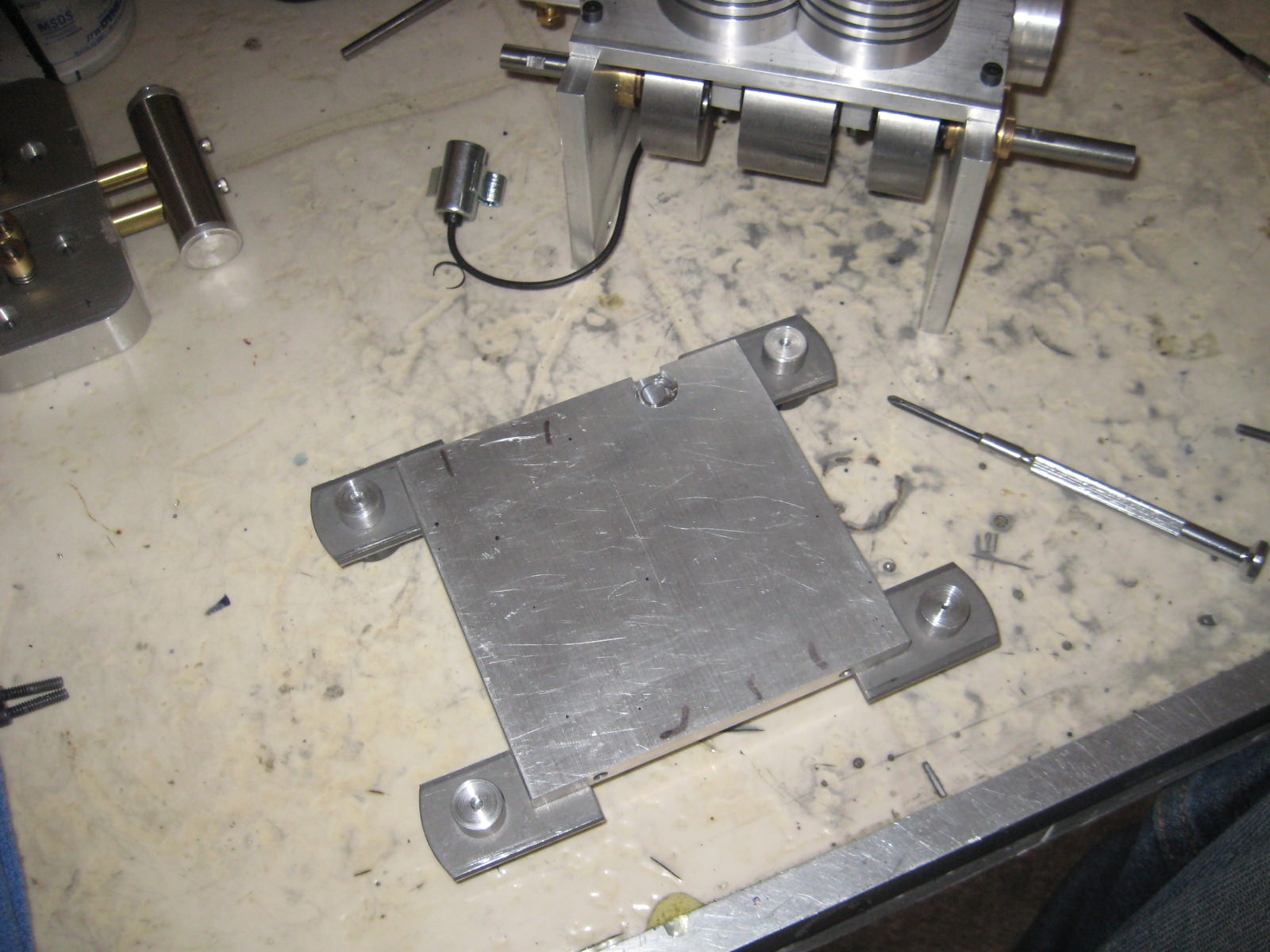

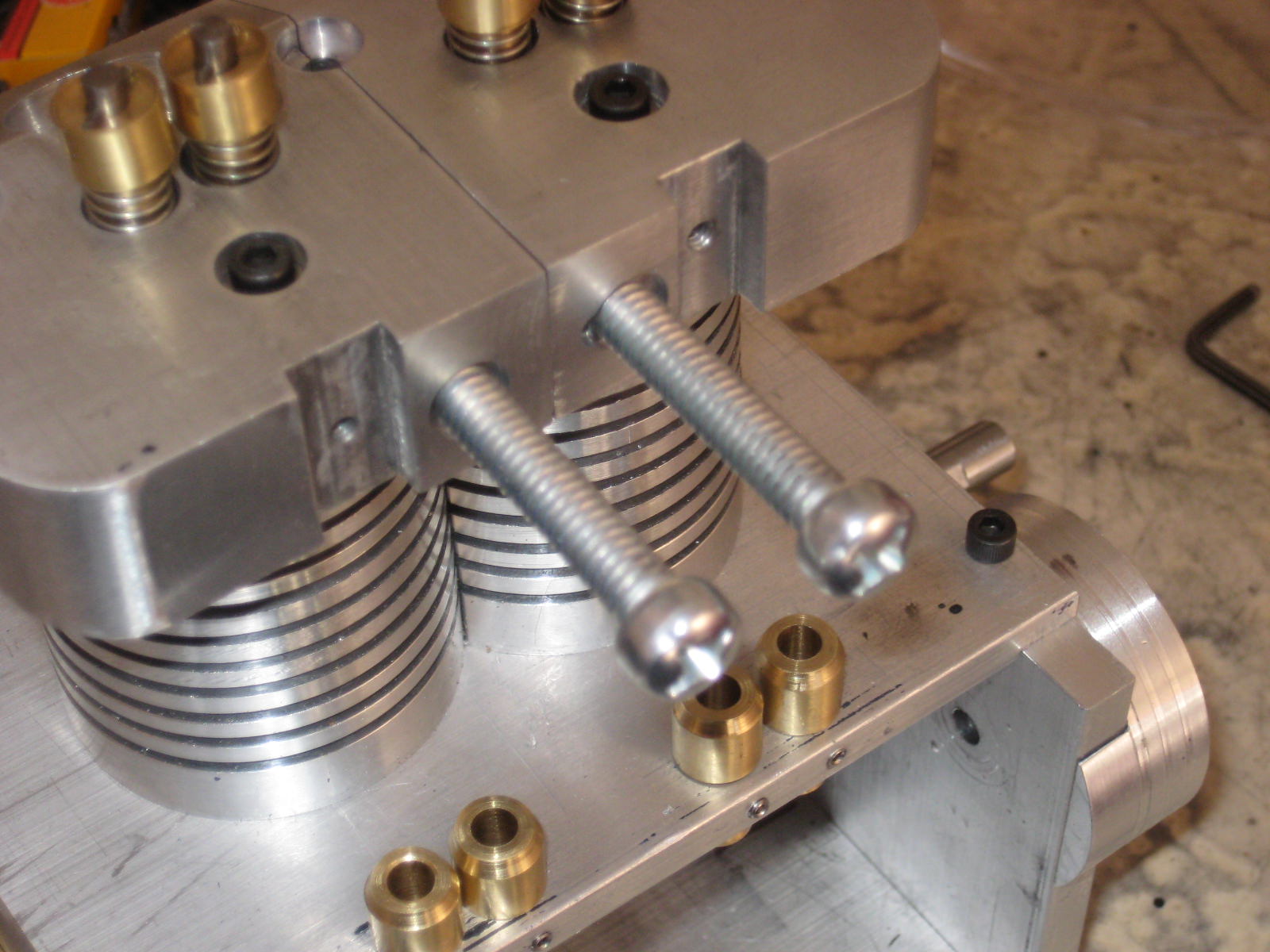

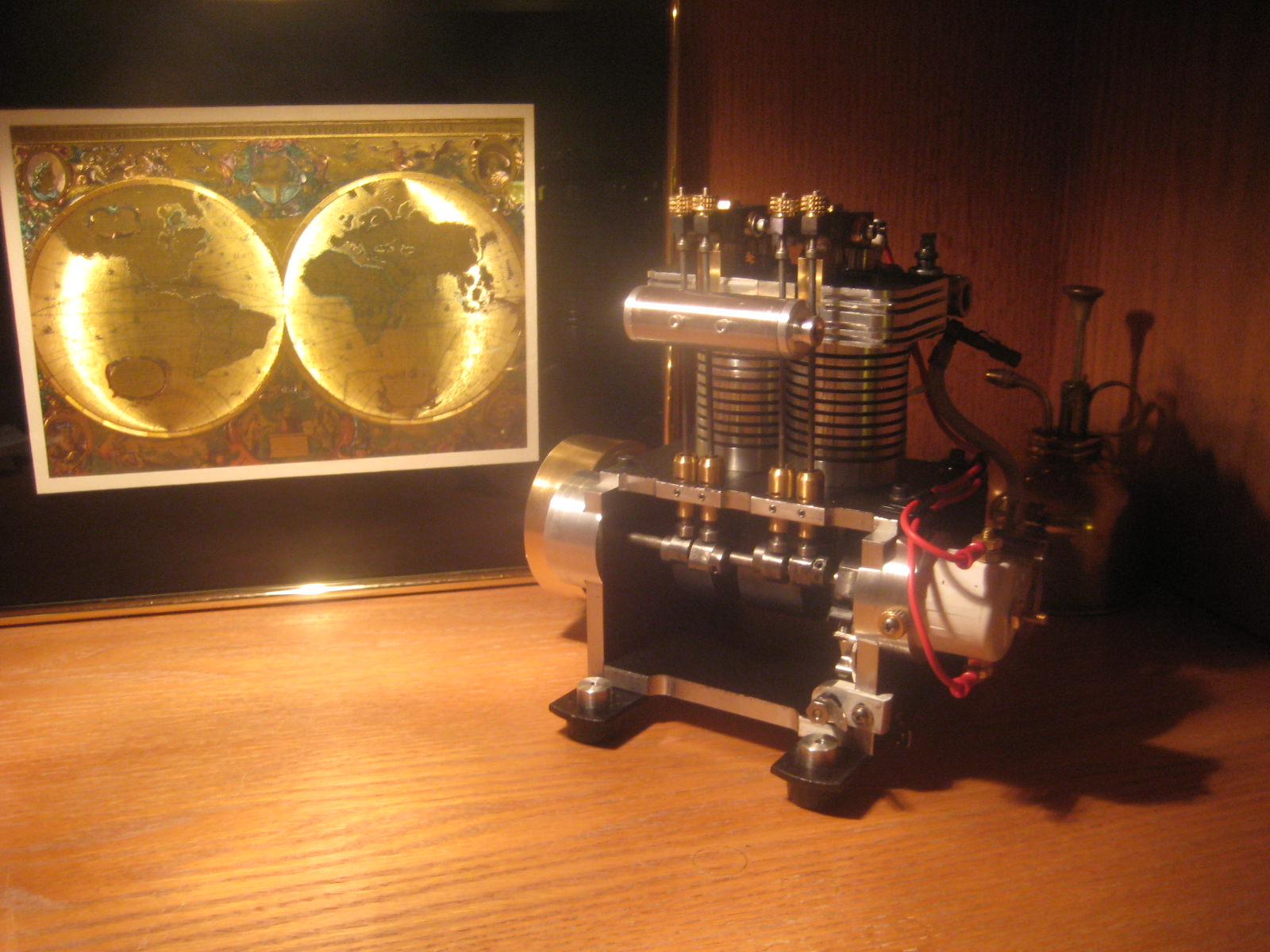

Rotor brass is located on the camshaft for line up with the plug leads. Distributor base is machined with a wrap around to the side of frame end plate and a matching piece serves as a timing gear guard at other end.

Plug lead screws are threaded in till contact and locked. Being a sweep contact, fine tune by finger rotating camshaft and feeling for it then. The screws were replaced with longer studs to fasten the wiring. Though a press fit to the base, a finger screw was added later to hold cap in its base.......cuzz I like doo dadz on the engine!