David Morrow

Well-Known Member

- Joined

- Sep 8, 2008

- Messages

- 227

- Reaction score

- 60

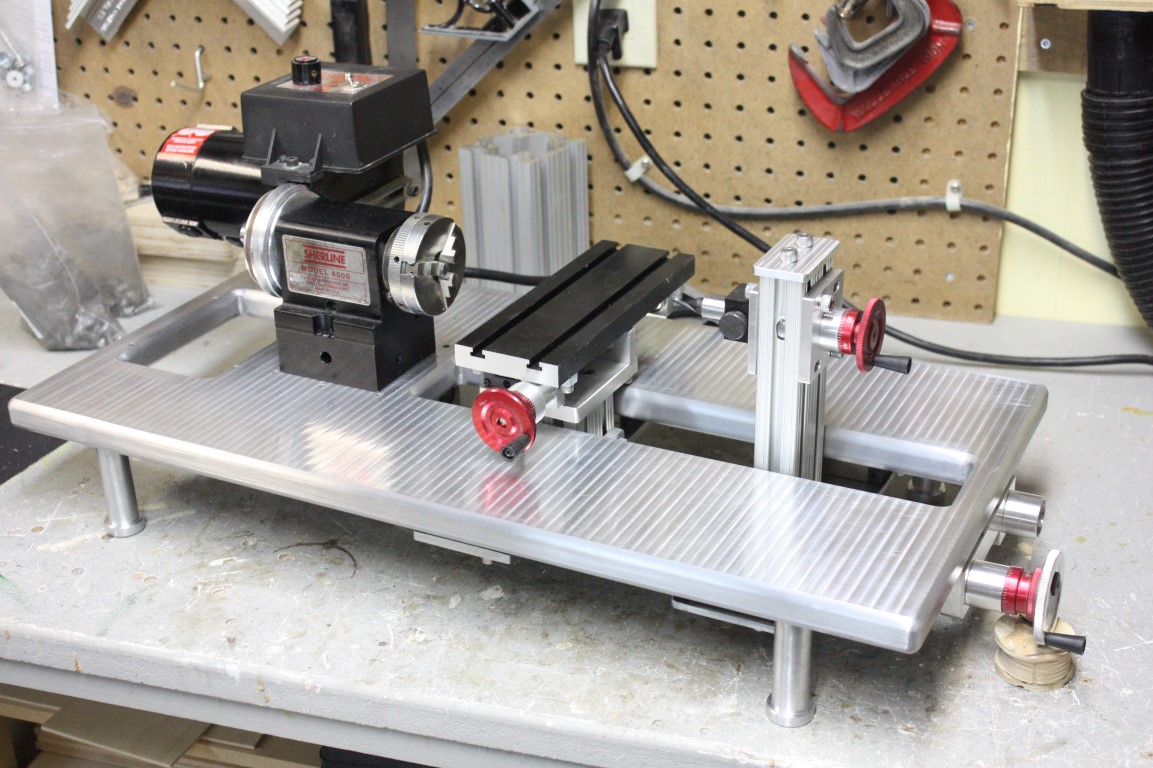

I really didn't need another lathe. I already had three. But, I did want a small lathe that I didn't have to stand up to use. I have a Sherline and it's just fine but I wanted something else with a bit more mass and a few other improvements. ( Improvements are in the eye of the beholder in this case.) I wanted the ways to be out of the path of swarf. I wanted a more accurate way without messing about with gibs. Zero backlash lead screws would be nice. I came up with a design in my head. It might not make financial sense to build your own lathe and, as long as costs were reasonable, I thought it would be a fun project. Initially, I had planned to design and build the headstock and tailstock, and source the motor to suit. With my Sherline lathe sitting on the bench beside me, I decided to just strip many of the needed part from that machine. If the project doesn't turn out, I'll just put the Sherline parts back together.

This is what I have completed so far :

The base is a slab of 12" x 24" aluminum that I resurfaced, milled and drilled on my CNC router.

You can see that in place of a conventional lathe way, I mounted a pair of linear rails and slides down below, out of the stream of falling chips and coolant.

I left the original handwheel on the tailstock but the tailstock will run along the Z axis by a handwheel mounted at the end next to the handwheel for the cross slide.

I don't have the lead screws yet but have ordered a set of zero backlash screws and nuts from Haydon Kerk. I've used their products on my two CNC routers and a small benchtop CNC mill and they are great.

I don't like the clearance of the handwheel for the cross slide so may raise everything up an inch later, once I get it operational.

There's still a bit of work to do but it's getting there.

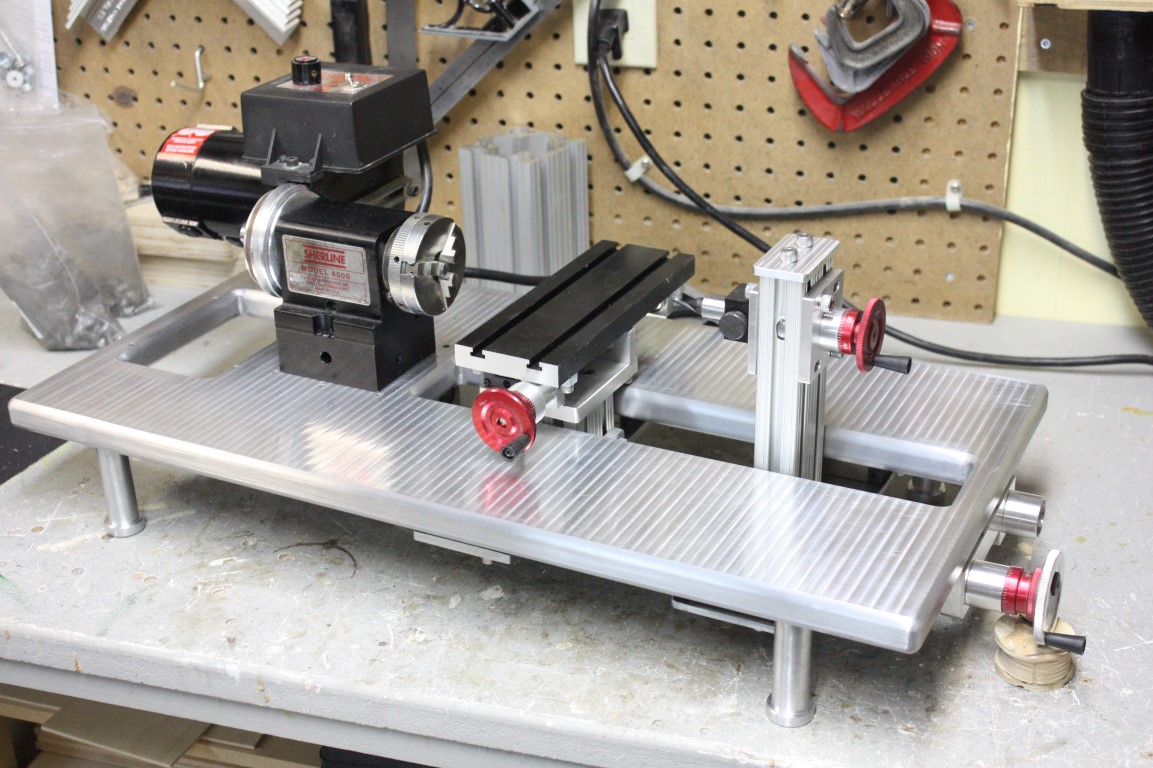

This is what I have completed so far :

The base is a slab of 12" x 24" aluminum that I resurfaced, milled and drilled on my CNC router.

You can see that in place of a conventional lathe way, I mounted a pair of linear rails and slides down below, out of the stream of falling chips and coolant.

I left the original handwheel on the tailstock but the tailstock will run along the Z axis by a handwheel mounted at the end next to the handwheel for the cross slide.

I don't have the lead screws yet but have ordered a set of zero backlash screws and nuts from Haydon Kerk. I've used their products on my two CNC routers and a small benchtop CNC mill and they are great.

I don't like the clearance of the handwheel for the cross slide so may raise everything up an inch later, once I get it operational.

There's still a bit of work to do but it's getting there.